- Home

- Products

- Video

- Blog

- Projects

- Quality Control

- About ALM

- News

- Support

- Contact Us

Views: 107 Author: Site Editor Publish Time: 2023-12-06 Origin: Site

Direct drive technology is one of the key technologies of high-end five-axis CNC machine tools,and it is also the inevitable trend of the development of various high-end CNC machine tools in the future.

Whether it is a linear motor driven linear motion shaft,or a DDR torque motor driven rotation shaft(cradle turntable),compared with servo motor+mechanical transmission,direct drive technology has the advantages of high precision,fast speed,high response,no wear,zero back backlash,and has a very high precision life.It has very high technical and economic value for the development of high-grade CNC machine tools.

●Traditional vs direct drive

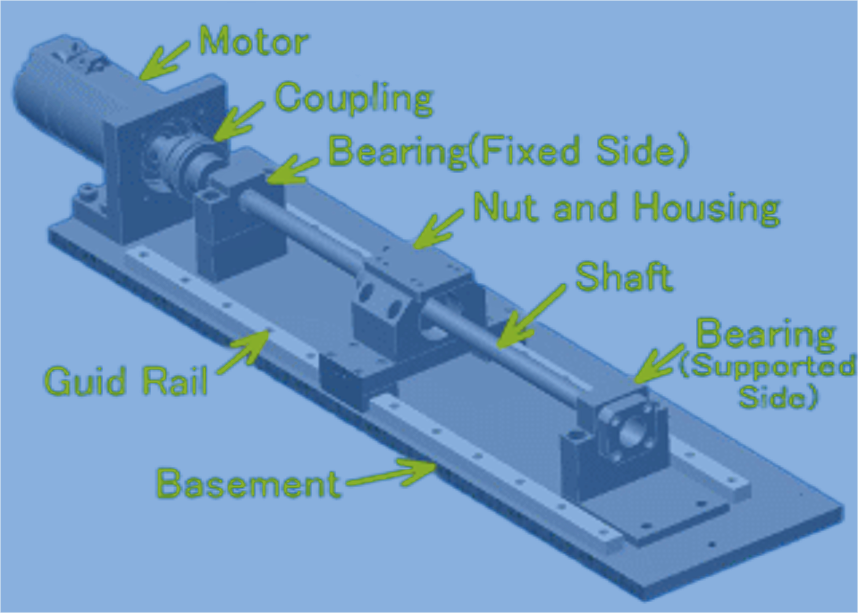

Servo Motor > Coupling > Ball screw > Nut holder > Load platform

●MHT linear motor for machine tools

Benefiting from our continuous research in electromagnetic solutions and processes,the MHT series linear motors have a thrust density about 20% higher than market products at the same mover volume and temperature rise.Our linear motor can meet the requirements of compact devices for high beat and high response speed.

The MHT series linear motor not only has high thrust density,but also achieves minimal cogging force.The speed fluctuation can reach around 3 ‰,and the position error can reach ±5 count at a uniform speed.

Through ALM's linear motor direct drive technology,high-end five-axis CNC machine tools have achieved a breakthrough in precision machining,bringing excellent application results to aerospace,marine manufacturing and other fields.

Linear Motors from China, Linear Motors Manufacturer & Supplier - ALM (autolinearmotion.com)