- Home

- Products

- Video

- Blog

- Projects

- Quality Control

- About ALM

- News

- Support

- Contact Us

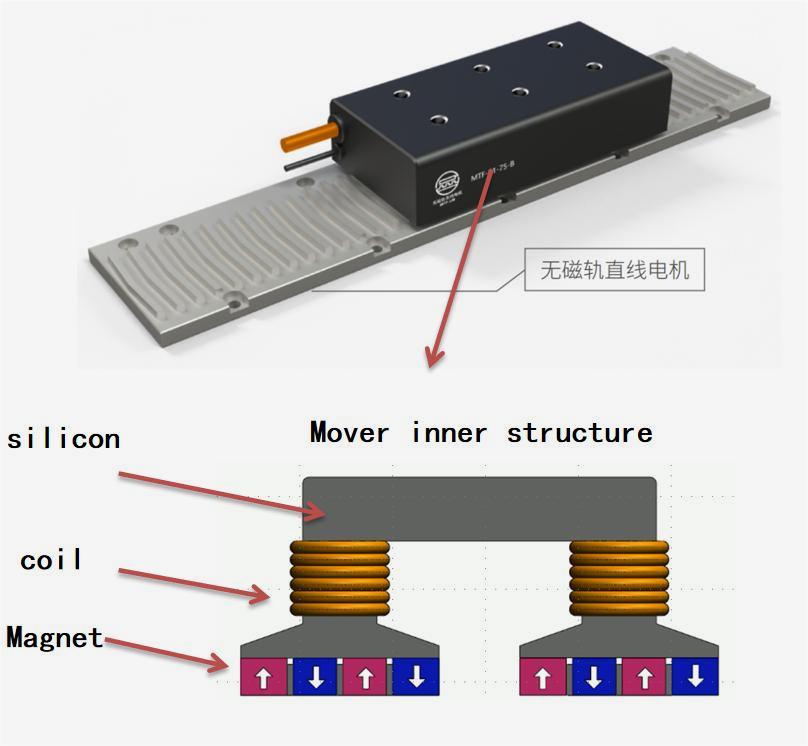

The stator of the magnetic-track-free(MTF)linear motor does not use magnets,but the powder magnetic conductive materials.This material with the features of high permeability,high saturation flux and is easy to manufacture by metallurgical die casting.MTF linear motors put the magnet inside the actuator,and when the actuator moves,the corresponding magnet moves.That is,the motor will have the excitation of the magnet with movement,the magnet movement to which part,which part of the electromagnetic force.Thus,as the rotary permanent magnet synchronous motor,the magnet utilization rate reaches 100%,no extra magnet is exposed.As a result,the cost of linear motors is greatly reduced and safety is improved.

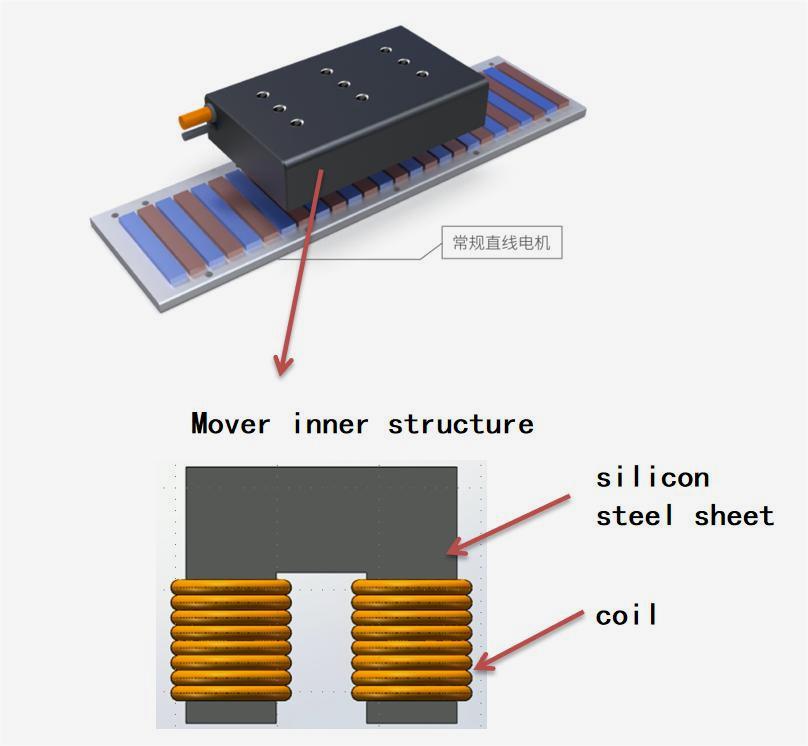

Magnetic track linear motor:Put the coil on the forcer and magnet on the stator

MTF linear motor:Coil + magnet is placed on the forcer,and non-magnetic material is used on the stator

●MTF Linear Motor VS Conventional Linear Motor

MTF Linear Motor

MTF Linear MotorWe proposed the Magnetic-track-free linear motor for the first time in industry based on the innovation in the magnetic field theory.The stator does not need the PMs any more,which can save massive rare-earth materials bring at least 70% cost saving,particularly on long track linear motors.By iteratively optimizing the design and the manufacturing craft,MTF linear motor obtained the extremely high force density,operating speed and moving precision.

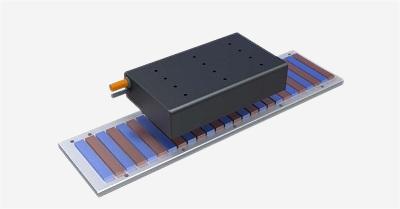

Conventional Linear Motor

Conventional Linear MotorLinear motor moves by the magnetic force produced by the magnetic field between stator and mover,so the mover and the stator are untouched.For the conventional linear motors,whether for the iron core or the ironless core linear motors,they need to lay the magnetic track built by the permanent magnets on the stator,so the motor can move by the magnetic force produced by the coil-generated magnetic field and the PM generated magnetic field.

●MTF Linear Motor Main Structure

Linear Motor Mover

MTF linear motors put the magnet inside the mover,and when the mover moves,the corresponding magnet moves.

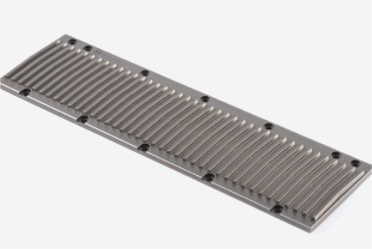

Linear Moter Stator

The stator of the magnetic-track-free(MTF)linear motor does not use magnets,but the powder magnetic conductive materials.

●MTF Linear Motor Series

| Series | Feature | Performance | Applications |

S1 | ●The use of non-magnetic rail sergs,affordable ●No magnetic field on the synth,safe,easy to protect,compact structure ●Light,small inertia ●Very low tooth groove force and electro-magnetic thrust fluctuations significantly reduce the vertical suction force(About 1/3 of conventional motors) | ●Up to 22G acceleration ●Up to 30m/s speed ●Thrust range from 160N-538N | ●Wafer detection ●Patch machine ●Crystal-fixing machine ●Welding wire machine ●PCB punching/testing ●Three-coordinate measuring ●Medical devices ●Universal automation |

S2 | ●The use of non-magnetic rail sergs.affordable ●No magnetic field on the synth,safe and easy to protect ●The length of the mover is moderate ●Medium weight linear motor ●Very low tooth groove force and electromagnetic thrust fluctuations ●Significantly reduce the vertical suction force(About 1/3 of conventional motors) | ●Up to 24G acceleration ●Up to 15m/s speed ●Thrust range from 320N-1076N | ●Crystal-fixing machine ●Welding wire machinePCB ●punching / testing ●The seventh axis of the robot ●Medical devices ●The up-and-down system ●Universal automation |

●MTF Linear Motor Advantages

More Safe

No magnetic field in stator,easier for assembling,much lower risk for operators.

More Adaptive

With low requirement for the ingress protection,and reduce the EMI grade obviously.

Easier for Protection

Not easy to attract the sundries and ashes into the motor,easier for protection.

Much Smaller Attraction Force

About ⅓ of the conventional linear motor attraction force can reduce the attraction force significantly,thus to increase the life expectancy and reduce operating noise.

Much Smaller Cogging Force

Benefited from the low attraction force and the specialized optimizing design,MTF linear motor can obtain the extremely low cogging force.