- Home

- Products

- Video

- Blog

- Projects

- Quality Control

- About ALM

- News

- Support

- Contact Us

Backlash can cause wear and inaccurate positioning,which can be detrimental to your application.Our anti-backlash nuts are designed to reduce or eliminate backlash in linear motion systems,providing smoother and more precise movement.As a professional anti backlash nut lead screw manufacturer and supplier,we also produce custom anti-backlash nuts and lead screws to meet specific customer requirements.

| Available lead screw material | ASTM1045,SUS303,SUS304,SS316,SS316L (other customized materials,according to customer requirements) |

Available lead nut material | Brass,Tin bronze,Phosphor bronze,Aluminum bronze,POM,PEEK,nylon,POK,Stainless steel,1045,Zinc alloy,Brass+Plastic,Aluminum alloy+Plastic,Brass+Steel,Self lubricating(No oil type) |

Available surface coating | Zinc-plated,nickel plated,hard chromium plated,fluorine coated,tungsten disulfide,black chorme plated |

| Quality standard | ISO2901-4,DIN103 |

| Note:Customized nuts and end machining are available upon drawing | |

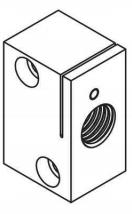

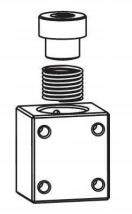

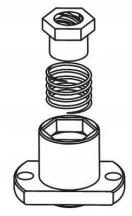

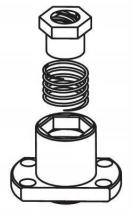

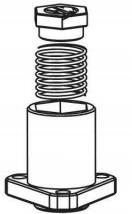

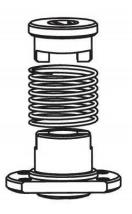

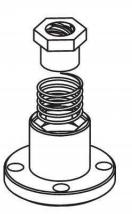

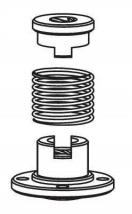

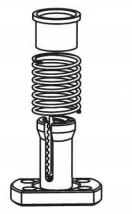

The following pictures show the common ALM anti-backlash lead screw nut structure.Other anti-backlash lead nut structures can be manufactured according to customer's drawings.

G

H

DCHT2

DCHT4

DCYT3

ECHT4

DCOT4

E

K

F

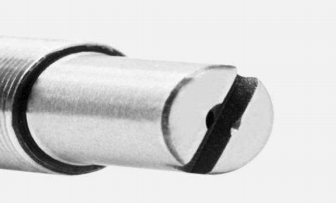

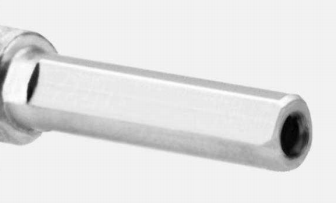

ALM provides lead screw shaft end machining custom services,the following is the common shaft end machining drawing,other lead screw shaft end machining according to customer requirements.

Milling Circlip

Processing Thread

Milling Keyway

Milling Slotted Drives

Milling Hex Socket

Milling Flat

Quiet,low maintenance.

High precision and long service life.

Clean and smooth,excellent surface finsh.

Cost-effective and helps customers save more costs.