- Home

- Products

- Video

- Blog

- Projects

- Quality Control

- About ALM

- News

- Support

- Contact Us

Views: 80 Author: Site Editor Publish Time: 2025-05-07 Origin: Site

Exploring planetary roller screws: applications and outstanding advantages

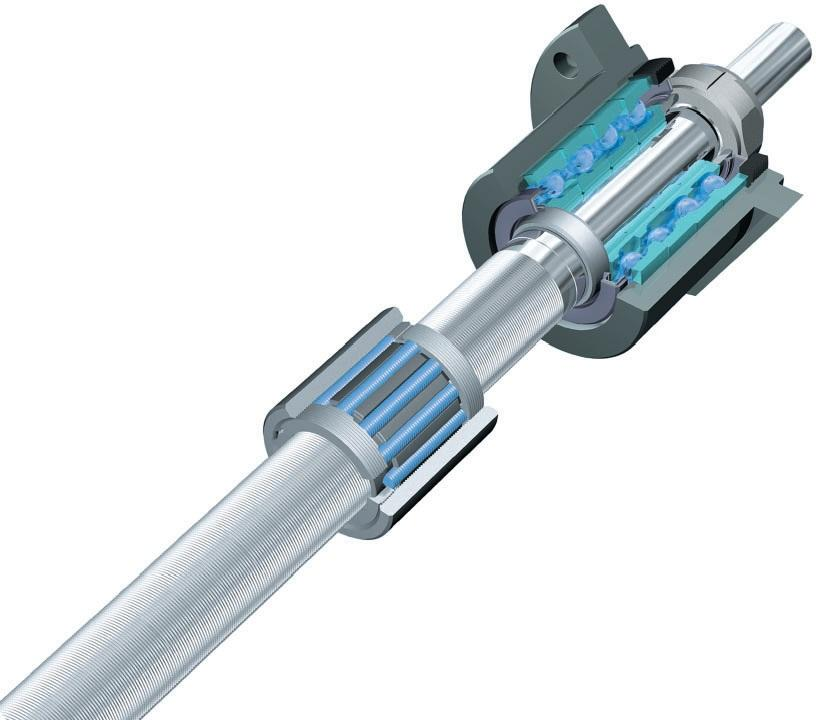

What is a planetary roller screw?

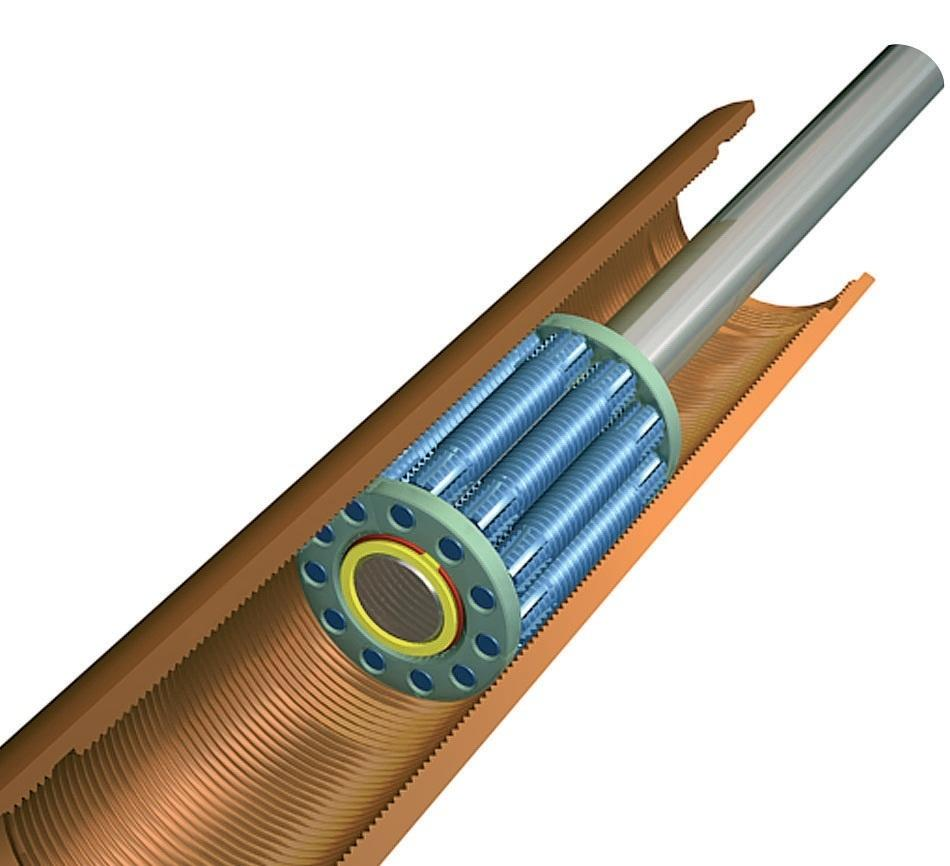

A planetary roller screw is a mechanism that converts rotary motion into linear motion. The rolling elements between the nut and the screw are threaded rollers. The numerous contact lines make the planetary roller screw highly load-bearing.

The widespread applications of planetary roller screws:

2.Automotive manufacturing industry: The automotive industry continuously pursues technological innovation, with planetary roller screws widely used in production processes. On robotic assembly lines, they assist robotic arms in accurately positioning and handling components, significantly enhancing assembly quality and production efficiency. In automotive testing equipment, these screws precisely apply force and displacement, providing reliable data support for vehicle performance tests.

3.Industrial machinery field: Industrial machinery requires reliable components capable of withstanding heavy loads and harsh operating conditions, making planetary roller screws a common choice. In machine tools like lathes, milling machines, and grinders, they drive cutting tools in linear motion, ensuring high machining precision. In industrial equipment such as presses and injection molding machines, these screws apply high pressure and achieve precise positioning, ensuring product quality consistency.

5.Renewable energy field: With the development of renewable energy industry, the demand for efficient and reliable equipment is growing. In wind power generation, planetary roller screws are used to adjust the angles of wind turbine blades, optimizing wind energy capture efficiency, even in wind farms with strong winds and complex environments. In solar power stations, they help solar panels track the position of the sun, ensuring maximum absorption of solar energy.

Planetary roller screws offer outstanding advantages:

2.Long service life: The unique design reduces wear on components, extending the life of the screws and decreasing maintenance and replacement frequency, making it a cost-effective choice in the long run.

3.High precision: Its precise design and manufacturing process ensure smooth and consistent linear motion, effectively reducing backlash and improving repeat positioning accuracy, suitable for high-precision fields such as semiconductor manufacturing and precision machining.

4.High-speed operation: Low friction and efficient load transfer characteristics allow planetary roller screws to achieve high-speed operation, meeting the speed requirements of applications like automated production and robotics.

5.Excellent rigidity: Multiple contact points provide exceptional rigidity to planetary roller screws, minimizing deformation under force and ensuring accurate linear motion, crucial for equipment requiring stable cutting forces like machine tools.

6.Compact design: Despite their powerful performance, planetary roller screws have a relatively small size, suitable for space-constrained environments and easy integration into existing systems, reducing retrofitting challenges.

In summary, planetary roller screws, with their unique design and significant advantages, have become an ideal choice for many industries. As technology continues to advance, they will undoubtedly play a important role in more innovative applications, continuously driving development and transformation in the field of mechanical engineering.

For more information, contact us right now!