- Home

- Products

- Video

- Blog

- Projects

- Quality Control

- About ALM

- News

- Support

- Contact Us

Views: 1 Author: Site Editor Publish Time: 2023-04-10 Origin: Site

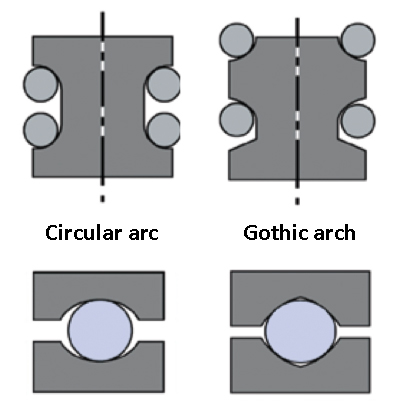

In linear guide with recirculating ball bearings,the raceway geometry defines the position of the bearing ball in relation to the track and bearing raceway(also known as the"carriage"or "slide").The two most common raceway geometrics are called circular arcs and Gothic arches.

The circular arc raceway geometry provides two-point contact between the ball and the raceway.

●Circular arc raceway geometry

The defining feature of the circular raceway geometry is that it allows the load-carring balls to contact the raceway at two points.This results in less differential slip and lower friction compared to other geometric shapes.One of the important design parameters of the profiled guide with circular arc contact is that the raceway curvature is within 51% to 52% of the ball diameter.This relatively low curvature means that bearings with circular arc geometers usually have a higher load capacity than other designs.

The two-point contact of the circular arc design also allows a certain amount of self-adjustment,so the accuracy and rigidity of the mounting base are less stringent than those of other geometric shapes.Note that since the circular arc geometry only has two points of contact,two rows of ball bearings are required on each side of the slider(bearing)to support the lift-off load.

●Gothic arch raceway geometry

Gothic arch raceway geometry provides higher rigidity by providing four points of contact for each load-carrying ball.However,bearings with Gothic arched geometry(albeit with four-point contacts) generally have lower load capacity than similar circular designs.This is because the raceway curvature is higher,55% to 60% of the ball diameter.(Recall from above that higher raceway curvature means lower load capacity.Four-point contacts also reduce the bearing's ability to compensate for inaccuracies in the mounting base,so mounting requirements for bearings with Gothic arched geometry are usually more stringent than those with circular geometry.

The main advantages of the Gothic arch design are their ability to withstand loads from any direction and relatively high moment load capacity.Therefore,bearings that use only two rows of recirculating balls(one row on each side of the bearing)usually have a Gothic arch arrangement.

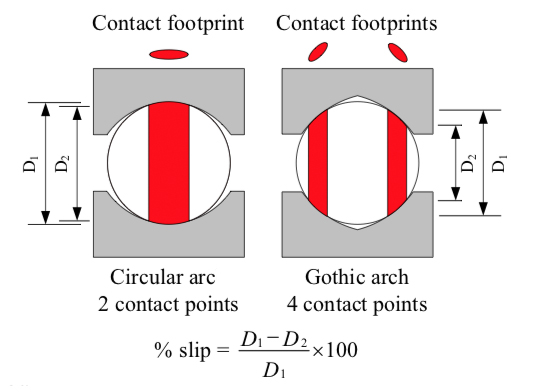

The greatest limitation of Gothic arch design is a phenomenon called differential slip.In cyclic ball bearings, the contact area between the ball and raceway is often called point contact,but because of the consistency between the ball and raceway,the contact area is actually an ellipse along the outside diameter of the ball.(Circular geometry represents two elliptic contact regions,and Gothic arch geometry provides four elliptic contact regions.

The elliptic contact area means that the diameter(and therefore,the rolling speed)of the ball roll will vary according to the meshing part of the ellipse. This provides the ball bearing with the opportunity to slip or slide rather than roll,which means the bearing will experience sliding friction. This phenomenon is called differential slip.

The greater the difference between the two diameters,the greater the slip difference in the ball over time.As shown in the figure below,the Gothic arch design results in a greater difference between rolling diameters,hence higher differential slip and higher sliding friction.In addition,differential slip increases with increasing contact area,so the Gothic arch design is somewhat limited in the amount of preload it can withstand before sliding friction becomes adverse to operating characteristics.

For circular arc geometry,the difference in diameter the ball can roll(D1-D2)is relatively small.For Gothic arch geometry,the difference in rolling diameter is large,resulting in higher differential slip and therefore higher friction.

Click to select ALM high quality linear guideways for your application:

Linear Guideways from China, Linear Guideways Manufacturer & Supplier - ALM (autolinearmotion.com)