- Home

- Products

- Video

- Blog

- Projects

- Quality Control

- About ALM

- News

- Support

- Contact Us

Views: 381 Author: Site Editor Publish Time: 2023-02-23 Origin: Site

In vertical applications,screw assemblies are usually preferable to belt or linear motors.Because the screw will prevent a catastrophic collapse of the load if the motor is powered down.However,vertical loads will still cause the screw to drive backwards,allowing the load to drop,albeit at a slightly more"controlled"rate,because it must overcome the screw's(low)efficiency,system friction and the screw's lead angle.

Lead Screws and ball screws have different tendencies to reverse drive - lead screws typically have a very low chance of reverse drive,while ball screws are more likely to allow load drop.This difference come down to efficiency.The low efficiency of a lead screw is often considered a negative performance factor and in vertical applications may prevent the nut from rotating freely under the weight of the load.If the lead of the screw is small,the assembly will be less likely to drive backwards.(A rule of thumb to prevent reverse drive is to use a lead smaller than 1/3 of the screw diameter.)

The high efficiency of ball screw drives makes them more likely than lead screw to back drives in vertical applications.However,if the application requires a ball screw for positioning accuracy,load capacity or rigidity,the designer has a way to determine the likelihood of a reverse drive occurring.

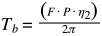

First,calculate the reverse drive torque,which is a factor of the load,the lead of the screw and the efficiency of the screw.

Tb = back driving torque(Nm)

F = axial load(N)

P = screw lead(m)

η2 = reverse efficiency(0.8 to 0.9 for ball screws)*

*Efficiency when back driving is typically less than the efficiency for normal operation.Be sure to check the manufacturer’s specification for the back driving efficiency.

To determine if this torque will cause reverse drive,compare it to the friction in the assembly- Ball nut drage torque,seal friction,and end bearing friction).If the back drive torque is less than the friction of the assembly,it is unlikely that the load will cause the screw to drive backwards.

Despite these calculations,safety is the most important consideration in vertical applications.Knowing the possibility of a load causing a screw assembly to drive backwards is not a "get out of jail free" card that ignores fail-safe mechanisms.Rather,it should help designers select the appropriate safety mechanism,such as an auxiliary brake or counterweight,to prevent equipment damage or personnel injury.

Click to select ALM high quality ball screw for your application: