- Home

- Products

- Video

- Blog

- Projects

- Quality Control

- About ALM

- News

- Support

- Contact Us

Views: 44 Author: Site Editor Publish Time: 2023-02-10 Origin: Site

When choosing a recirculating linear guide,several criteria need to be specified,including size,preload,and accuracy.Although the term "precision" is usually used in a general sense,it specifies five characteristics when referring to recirculating ball or roller guides:

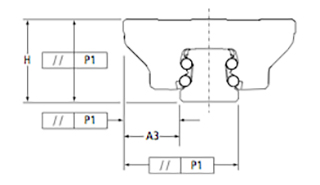

1.Height tolerance of guide and block assembly

2.Allowable height difference between multiple blocks on the same track

3.Width tolerances for guide and block assembly

4.The permissible width difference between multiple blocks on the same track

5.Parallelism between guide reference edge and block

The choice of accuracy grade of linear guide depends on the installation layout of guide rails and bearing and the required travel accuracy.

Accuracy class specifies tolerances for height,width,and parallelism.

●Mounting considerations

There are three basic installation schemes for recirculating linear guides:a single block on a single rail,multiple blocks on a single rail,and multiple blocks on multiple rails.

●Single block on a single rail

For a component consisting of a single guide rail and a bearing block,the height(1)and width(2)tolerances of the component are important not only for mounting the rail to its base,but also for mounting external loads or tools to the bearing block.In this configuration,the positioning requirements of the application are the main factor in selecting the accuracy level.For example,applications that use rigid tools or require strict tolerances to maintain the position of the payload should use higher precision bearing seats and guides.

●Multiple blocks on a single rail

Any deviation from height(2)or width(4)can be a problem when more than one bearing block is mounted on the guide rail.This is especially true when loading a payload or tool onto a bearing.Height differences can lead to uneven load on the linear guide assembly,resulting in premature failure of heavier loaded bearings.When loads are rigorously pinned or fixed to multiple bearing blocks on a single guide rail,higher accuracy classes are usually required to avoid uneven loads on bearings.

●Multiple bearings on multiple rails

The most common configuration of a recirculating guide is probably a combination of two guide rails in parallel,each with two bearing blocks,because it breaks down the torque on the bearing into vertical and horizontal forces.However,this arrangement means that the six components(two guides and four bearing blocks)must be aligned.In this case,specifications1,2,3,and 4 all play a role in the loads generated on the components.Does this mean that"super"precision bearing and rails are required when selecting this configuration?Not necessarily,but it is usually recommended to use a linear guide accuracy rating of "high" or above.

●Travel accuracy

Linear guide accuracy grade also plays an important role in the running behavior of bearings,which is a performance characteristic most people associate with the term "accuracy".

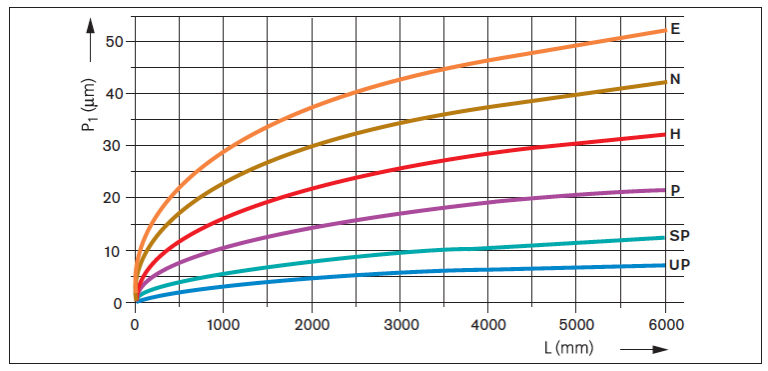

Regardless of size,preload,or mounting configuration,specification5(the parallelism between the guide reference edge and the block)plays an important role in determining the stroke accuracy of the guide system.This parallelism tolerance specifies the position behavior of the bearing block as it moves under the guide rail.In other words,does the bearing block seem to deviate from side to side or up and down during travel?

The parallelism of a linear guide depends on its accuracy class and the length of the rail.

Taking the dispensing machine as an example,due to the movement of the bearing to the left and right leads to the fluctuation of the distance between the dispensing head and the workpiece,the combination of guide rail and block with lower precision(meaning that the reference edge of the guide rail and the relative lack of parallelism between the block)will lead to changes in the thickness of the glue.If glue follows a horizontal path,the up and down movement of the bearing seat will prevent glue from being distributed in nice straight lines.

Some designers believe that using higher precision linear guides allows for lower precision mounting surfaces,requiring less time and cost to process and prepare.In other words,the precision of the guide assembly makes up for the lack of precision of the mounting surface.But the opposite is true:guide rails tend to conform with the surface on which they are mounted.To realize the full benefits of higher precision linear guides,the mounting surface shall be machined to at least the same standard as the guide.

Click to select ALM high quality linear motion components for your application:

www.autolinearmotion.com/products.html