- Home

- Products

- Video

- Blog

- Projects

- Quality Control

- About ALM

- News

- Support

- Contact Us

Views: 124 Author: Site Editor Publish Time: 2023-03-06 Origin: Site

One of the key criteria in the specification is preload when choosing the recirculating linear guide.Linear guide preload eliminates the clearance between the bearing block and the guide,thereby increasing rigidity and reducing deflection when external loads are applied.The following are the main factors to consider when choosing linear guide preload.

●Positioning Accuracy

Linear guides without preload(often called "clearance" because of the clearance between the raceway of the bearing block and the guide)allow some clearance in motion,which can negatively affect positioning accuracy.For applications where position accuracy is important,such as assembly and dispensing,linear guides with light preload(2%)are generally recommended.Higher preloads do not necessarily provide better positioning accuracy unless deflection becomes a factor.

●Deflection

The higher rigidity of the linear guide,the less deflection it experiences.Even a small deflection on the bearing block will be amplified at the end of the arm tool.This makes preload an important factor in applications where tools or work areas are located away from linear guide components.For example,machine tools often have to move heavy loads that are positioned a long distance from the bearing block.In such applications,high rigidity and low deflection are required for precise machining of parts,typically requiring a heavy preload of 5% to 8%.

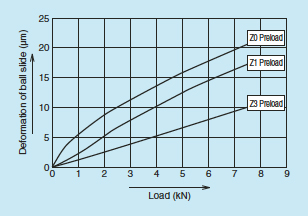

Deflection of linear guide under no preload (Z0),light preload(Z1)and medium preload(Z3).

●Linear Guide Layout

Profiled linear guides are often used in configurations with two parallel profiled guides and two bearing blocks per guide,creating in a square or rectangular pattern. This arrangement provides optimal support for torque loads in roll,pitch, and yaw directions. Although alignment of multiple guides and bearing block is always important,alignment becomes even more important if bearings are preloaded.

An example:when two profiled guides are used in parallel,the slider is preloaded,and the allowable offset in the vertical direction(usually expressed as S1)is less than the offset when the slider is not preloaded.If the maximum vertical offset is exceeded,a roll moment is introduced into the bearing blocks,which shortens the bearing life.Thus,while higher preloads can reduce deflection and provide better positioning accuracy,it also requires more precise machining of the mounting surface.

Vertical offset between guides,S1.

Click to select ALM high quality linear guideways for your application:

Linear Guideways from China, Linear Guideways Manufacturer & Supplier - ALM (autolinearmotion.com)