- Home

- Products

- Video

- Blog

- Projects

- Quality Control

- About ALM

- News

- Support

- Contact Us

Views: 5 Author: Site Editor Publish Time: 2022-12-30 Origin: Site

Clean rooms are most commonly associated with applications in the semiconductor,electronics,and medical device industries.Other industries such as aerospace,pharmaceuticals,food and beverage also use cleanroom environments in some applications.

Cleanrooms are common in semiconductor manufacturing.

Friction is the enemy of a cleanroom

The primary goal of using linear motion systems in cleanroom applications is to keep the particles to a minimum.But linear motion components depend on sliding or rolling motion,which inevitably produces particles due to friction and wear between surfaces.So one of the main areas of concern should be minimizing friction.

Plain bearings(left)rely on sliding contacts,which exhibit higher friction and particle formation than rolling contacts in recirculating bearings(right).

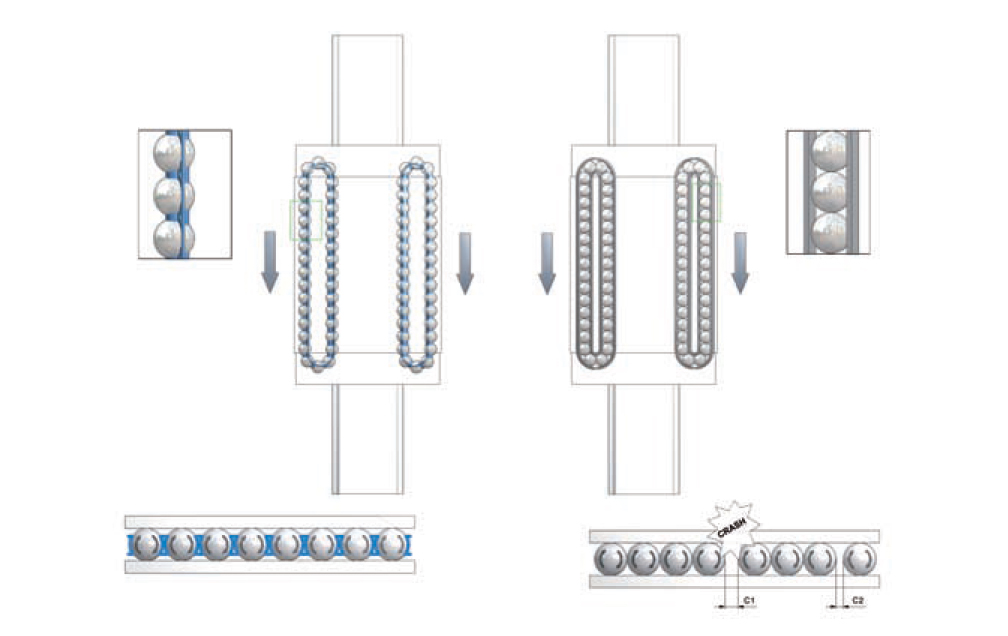

Linear ball bearings and ball screws are a better choice than plain bearings and lead screws in most cleanroom applications.However,standard full-contact seals on linear ball bearings and ball screws slide in contact with the guide rail or screw shaft,so low-friction or non-contact seals are superior to full-contact designs.Recently,some manufacturers have performed particle counting tests to demonstrate that ball spacers or ball chains can reduce particle in profiled rail guides and ball screws.

Ball separators(also referred to as ball chains or caged balls)can be useful in cleanrooms because they prevent ball-to-ball contact, which can cause particle generation.

Lubrication is both friend and foe

Lubrication not only helps to reduce friction and ensure proper operation,it can also be used to "trap"some of the particles produced by linear bearings or screws and prevent their release into the environment.However,if released into the atmosphere,the lubricant itself could become a source of pollution.This is especially problematic for ball screws,which "sling off" lubrication as they rotate.This is why many cleanroom applications require cleanroom approved lubricants.These special formulations contain no(or fewer)additives that contain solid particles,such as aluminum,silica,and PTFE.

Cleanroom-friendly materials are a must

The preferred materials for cleanroom are stainless steel and PVC,but aluminum and carbon steel are the main materials used in linear motion components.However,there are ways to make aluminum and standard carbon steel compliant with cleanroom standards.For example,anodizing aluminum,gives it good corrosion resistance.Carbon steel parts can be treated with a cleanroom compatible protective coating,such as black chromium or nickel,to prevent oxidizing.

A variety of miniature guides and micro screws are available in stainless steel versions,making them ideal for cleanroom applications with short travel lengths and light loads.Miniature versions usually offer low friction seals and low preload as standard options,so they generate essentially less particles than full-size versions.Also keep in mind that fasteners are often coated with a black oxide finish and have a high particle shedding rate even if these components are static.For clean room applications,stainless steel hardware should be used whenever possible.

Miniature linear guides and ball screws are usually offered in stainless steel versions, making them ideal for clean room applications.

Systems with reduced contact and friction

One way to eliminate or reduce many of the above problems is to use essentially "clean" linear motion components and systems.These include air bearings for guiding and linear motors for driving.Both systems eliminate sliding or rolling contact,so they have little friction and produce no particles.

https://www.autolinearmotion.com/