- Home

- Products

- Video

- Blog

- Projects

- Quality Control

- About ALM

- News

- Support

- Contact Us

Views: 9 Author: Site Editor Publish Time: 2024-02-28 Origin: Site

For linear stepper motor,precision lead screws are widely used.As to shaft end machining,two processes are commonly applied.One is to make raised spline.And another is Knurl processing.So Raised spline VS Knurl;what’s the difference between them?

●Raised spline

Raised spline is to process a certain shape and depth of concave and convex lines on the lead screw,usually in the following two ways:

The first way is to make raised spline on the lead screw directly and the raised spline line is parallel to the lead screw (as shown in the figure below),but under this way the lead screw surface is rough,the accuracy is low,and the appearance looks not beautiful.

Another way is to use adhesive to attach the lead screw to a brass sleeve,then make raised spline on the brass sleeve. The raised spline line is perpendicular to the lead screw.However,the adhesive is easy to fall and unstable over time.This can result in a decrease in performance and accuracy of the lead screw.

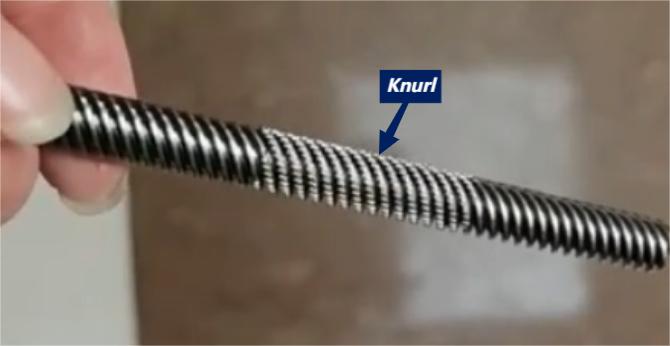

●Knurl

The Knurl process can make a uniform pattern on the lead screw.This process creates a one-piece design that is more stable and reliable.The knurled process ensures high performance and accuracy of the lead screw and motor.So Knurl process is becoming more and more popular.

ALM company specializes in producing motorized lead screws.With our mature Knurl process,we can mass produce high-quality lead screws for motors. If you are in search of reliable lead screws for motors, contact us via email: sales@autolinearmotion.com

Professional manufacturer for complete selection of lead screws - ALM (autolinearmotion.com)