- Home

- Products

- Video

- Blog

- Projects

- Quality Control

- About ALM

- News

- Support

- Contact Us

Views: 49 Author: Site Editor Publish Time: 2023-03-31 Origin: Site

For electromechanical linear actuators,integrated design saves space,reduces complexity,and reduces total cost of ownership,while reducing the number of parts required for repair or replacement.The hybrid stepper linear actuator is a design with multiple uses in medical,3D printing and assembly applications that combines a ball screw or lead screw with a hybrid stepper motor.The following are examples of excellent applications of these linear actuators,thanks to their compact size,precise positioning,and good velocity-force characteristics.

●Precision metering and dosing pumps

Whether in the medical,semiconductor or assembly industries,hybrid stepper linear actuators are the ideal solution for driving small precision pumps,thanks to their extremely compact footprint and ability to move at high speed and accuracy.

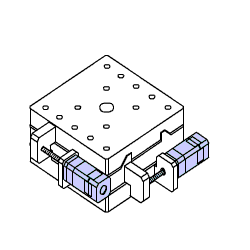

●XY tables

One of the key design principles of the XY workbench is to keep the footprint as compact as possible,and hybrid stepping linear actuators contribute to this goal by keeping the drive system small while providing high thrust and positioning accuracy.

●CNC machines and 3D printers

Although one removes material(CNC machines)and the other adds material(3D printers),both applications require very high positioning accuracy and reliability-two performance areas in which hybrid stepper motor linear actuators excel,especially when used with microstep control in closed-loop systems.

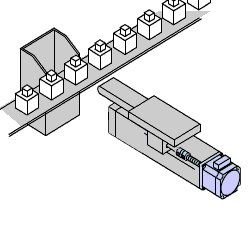

●Diverting and Sorting

In conveyor applications,there are often stations that need to shunt or sort products due to quality problems or manufacturing processes.In these applications,hybrid stepping linear actuators provide fast extension and retraction with good thrust and simple control.

Click to select ALM high quality linear motion components for your application:

Linear Module, Ball Screw, Lead Screw- ALM (autolinearmotion.com)