- Home

- Products

- Video

- Blog

- Projects

- Quality Control

- About ALM

- News

- Support

- Contact Us

Views: 42 Author: Site Editor Publish Time: 2024-01-16 Origin: Site

ALM specializes in manufacturing precision-grade trapezoidal lead screws,offers a wide range of options for machining trapezoidal lead screw shaft ends to meet customer requirements.The following shows the common trapezoid lead screw shaft end processing pictures:

Milling Circlip

Processing Thread

Milling Keyway

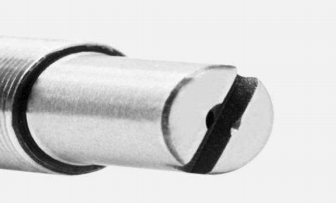

Milling Slotted Drives

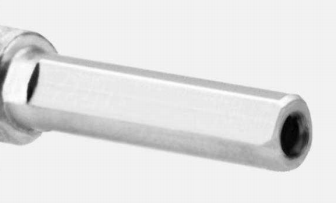

Milling Hex Socket

Milling Flat

1.Plain Shaft End:This is the simplest form of trapezoidal screw shaft end,where the end is left plain without any additional features or modifications.It is suitable for applications where the shaft end does not require any specific functionality.

2.Keyway Shaft End:In this type of machining,a keyway is cut into the shaft end to allow for secure and precise connection with other components.Keyways ensure proper alignment and torque transmission in applications that require rotational motion.

3.Threaded Shaft End:For applications that require a threaded connection,ALM can machine trapezoidal screw shaft ends with external or internal threads.External threads are useful for connecting nuts or other components,while internal threads are suitable for attaching accessories or additional components.

4.Milling Hex Socket: Also known as a hex socket or Allen socket.This allows for easy installation and removal using a hex key or Allen wrench.

5.Milling Circlip:In the case of a lead screw,the circlip shaft end is typically used to hold a nut or other components in place on the shaft.The circlip is inserted into a groove on the shaft,and its spring-like properties allow it to expand and secure the components in position.

6.The milling slotted drives are slots or grooves machined into the end of the lead screw shaft.These slots are used to engage with a mating part,such as a nut or a drive mechanism, to transmit the rotational motion from the drive source to the lead screw.

Apart from the above options,ALM also offers various customized shaft ends.Customers can provide specific drawings or requirements.

For more information about our lead screw,please contact us email:sales@autolinearmotion.com

Professional manufacturer for complete selection of lead screws - ALM (autolinearmotion.com)