- Home

- Products

- Video

- Blog

- Projects

- Quality Control

- About ALM

- News

- Support

- Contact Us

Views: 26 Author: Site Editor Publish Time: 2023-04-24 Origin: Site

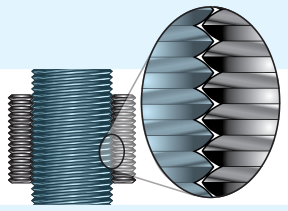

Screw drive is some of the most common mechanical linear actuation methods.Planetary roller screw is one of several screw types,including lead screw and ball screw.Planetary roller screws use threaded rollers that engage with the gear rings at each end of the nut.The roller rotates on its axis and moves around the nut in a planetary configuration.

The planetary roller screw is able to deliver higher forces because the roller has more contact with the screw thread.

One of the advantages of planetary roller screws is that they have a high force transfer capability because of the apparent contact between the roller and the thread.They provide high force,high speed operation,long lasting and require little maintenance.

The geometry of the planetary roller screw provides more contact points than the ball screw.As a result,roller screws typically have higher dynamic load capacity and rigidity than similar sized ball screws.Fine threads provide a higher mechanical advantage,so less input torque is required for a given load.

One drawback is that the increased contact area generates more heat for the same amount of work.Ball screws,due to fewer contact points,can be slightly lower in high duty ratio and high speed applications due to higher thermal management efficiency.

Typical planetary roller screw,showing the nut enclosing the roller.

Typical planetary roller screw,showing the nut enclosing the roller.However,planetary roller screws provide higher dynamic load ratings and longer service life even in repeated stress applications such as pressing,inserting,or riveting.In fact,planetary roller screws are being specified for applications that were once driven by hydraulic cylinders.

Click to select ALM high quality ball screw for your application: