- Home

- Products

- Video

- Blog

- Projects

- Quality Control

- About ALM

- News

- Support

- Contact Us

Views: 83 Author: Site Editor Publish Time: 2022-11-29 Origin: Site

A linear guide(or linear bearing)is a mechanical element that allows for relative motion between two surfaces,with one surface supporting the other and with minimal friction between the two.There are two basic types of linear guides:plain and rolling element.While their general function is the same,their design and performance are quite different.

●Linear guides with plain(sliding)motion

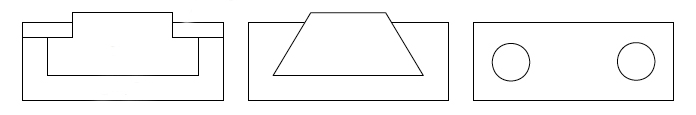

Plain bearings are the simplest type of linear guide and rely on sliding contact between two surfaces.Their construction can be boxway,dovetail or shaft and bushing.Boxway bearings can withstand the highest loads,while dovetail designs require less machining and assembly precision.Plain bearing bushings are easy to manufacture and install,but their lack of a supporting shaft makes them limited in load capacity and susceptible to deflection.

Plain bearing linear guides can be boxway,dovetail,or shaft and bushing design

While metal surfaces provide the highest stiffness and load capacity,plain bearings can also be made of plastic or composite materials to achieve high corrosion resistance and inherent lubrication properties.It is important to note that sliding contact should always be between different materials,with one element harder than the other.This allows the wear to be concentrated in the softer components.

Compared with rolling bearings,plain bearings have a higher friction coefficient,usually 0.05 to 0.1.However,unlike rolling elemnt,they can withstand impact loads and vibrations without causing significant damage to the surface.plain bearings are also less sensitive to pollution,and few catastrophic failures occur.

●Linear guides with rolling motion

Rolling element linear guides add ball or rollers between two bearing surfaces.Rolling bearings can be recirculated(profiled linear rails or linear bushings/linear bearing rails)or non-recirculated(CAM roller rails or cross roller sliders).The recirculating design allows unlimited movement along the length of the guide or shaft,where the non-recirculating design is limited in stroke by the length of the bearing.

In an non-recirculating linear guide(left),the bearing housing(1)contains a rolling body(2)that moves a limited distance along the base(3).In a recirculating linear guide,the rolling element is recirculated through the bearing housing so that the bearing can travel an infinite distance(limited only by the length of the guide or shaft).

A significant advantage of rolling linear guides is the low friction coefficient,usually between 0.005 and 0.01.Because they are made of bearing steel,they have a higher load capacity and can be pre-loaded for very high rigidity.However,preloading increases friction,which must be taken into account when determining the size of the linear guide of the rolling element.

Although sliding linear bearings can be made of a variety of materials,the diversity of contour track type rolling body bearings lies in their track geometry and raceway configuration.The track geometry defines how the rolling body makes contact with the raceway.The anomalous track geometry can be circular,providing lower friction,or Gothic arches,providing higher moment capacity.In addition,the raceway arrangement on the profiled rail can be face to face or back-to-back.A face to face arrangement has equal load capacity in all directions,while a back to back arrangement provides greater torque capacity.

Face-to-face raceway arrangement

Back-to-back raceway arrangement

The life of the linear guide rail of the rolling body is determined by calculating the life of the L10 bearing.The life of the L10 bearing is a theoretical but statistically formulaic prediction of the distance the bearing can travel before reaching its fatigue life.The life of the L10 depends on the type and size of the load,although environmental factors such as shock,vibration and pollution can shorten the service life of the rolling bearings.

Click to select ALM high quality linear motion components for your application:

www.autolinearmotion.com/products.html