- Home

- Products

- Video

- Blog

- Projects

- Quality Control

- About ALM

- News

- Support

- Contact Us

Views: 37 Author: Site Editor Publish Time: 2023-03-24 Origin: Site

From a mechanical perspective,one of the more challenging applications in linear motion traditionally involves moving two or more loads independently,as required by some handling,transportation,and inspection applications.While using multiple linear systems or pre-assembled actuators is a simple mechanical solution,this option typically requires a significant amount of space and cost.But there are several types of linear systems that allow users to install multiple loads and move each load independently.

One of the most common linear motion systems used to move multiple loads independently is the linear motor.Most linear motor designs(with or without iron cores)use forcers that contain windings and are powered directly,so multiple forcers can be mounted on the rail and controlled using different move profiles and strokes.Linear motors with multiple forcers or sliders are usually used for high dynamic movements that require very precise control of speed or position.In fact,many conveyor systems based on linear motors are based on the concept of linear motors with multiple forcers.

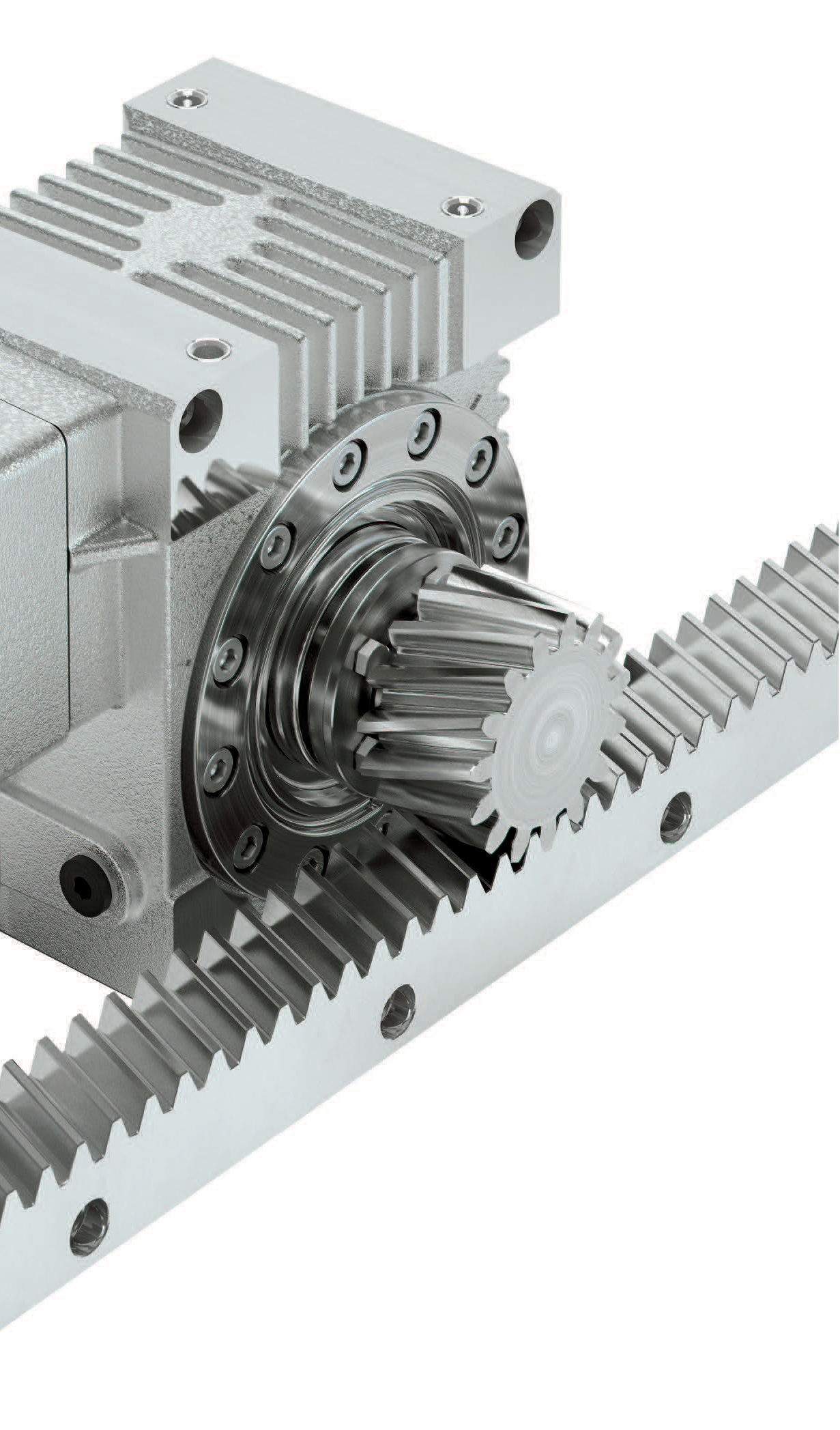

Another traditional linear motion system that allows multiple loads to move independently is the rack and pinion drive.Because the motor and gearbox are mounted directly onto the pinion,it is relatively simple to mount additional motor-pinion combinations on a single rack,each programmed for a specific stroke and move profile.Rack and pinion systems with multiple independent sliders are ideal for large gantry frames and transportation applications,often used in robotic transmission units.

The pinion is driven directly by a motor-transmission combination,making it easy to assemble multiple pinion gears onto a single rack,with each pinion driven independently.

There are also linear actuator designs that use two ball or lead screws-one with left-hand thread and one with right-handed tread- pinned or welded together.Each ball screw or lead screw has a nut and slider,and a motor drives the entire assembly.This setting allows the sliders to move at the same time,but in opposite directions-using the same moving profile towards or away from each other.This arrangement is less flexible than the linear motor,rack and pinion described above,but is useful in applications that require clamping-type motion with precise force and speed control.

Ball screw or lead screw-driven linear actuators

Click to select ALM high quality linear motion components for your application:

Linear Module, Ball Screw, Lead Screw- ALM (autolinearmotion.com)