- Home

- Products

- Video

- Blog

- Projects

- Quality Control

- About ALM

- News

- Support

- Contact Us

Views: 15 Author: Site Editor Publish Time: 2024-01-31 Origin: Site

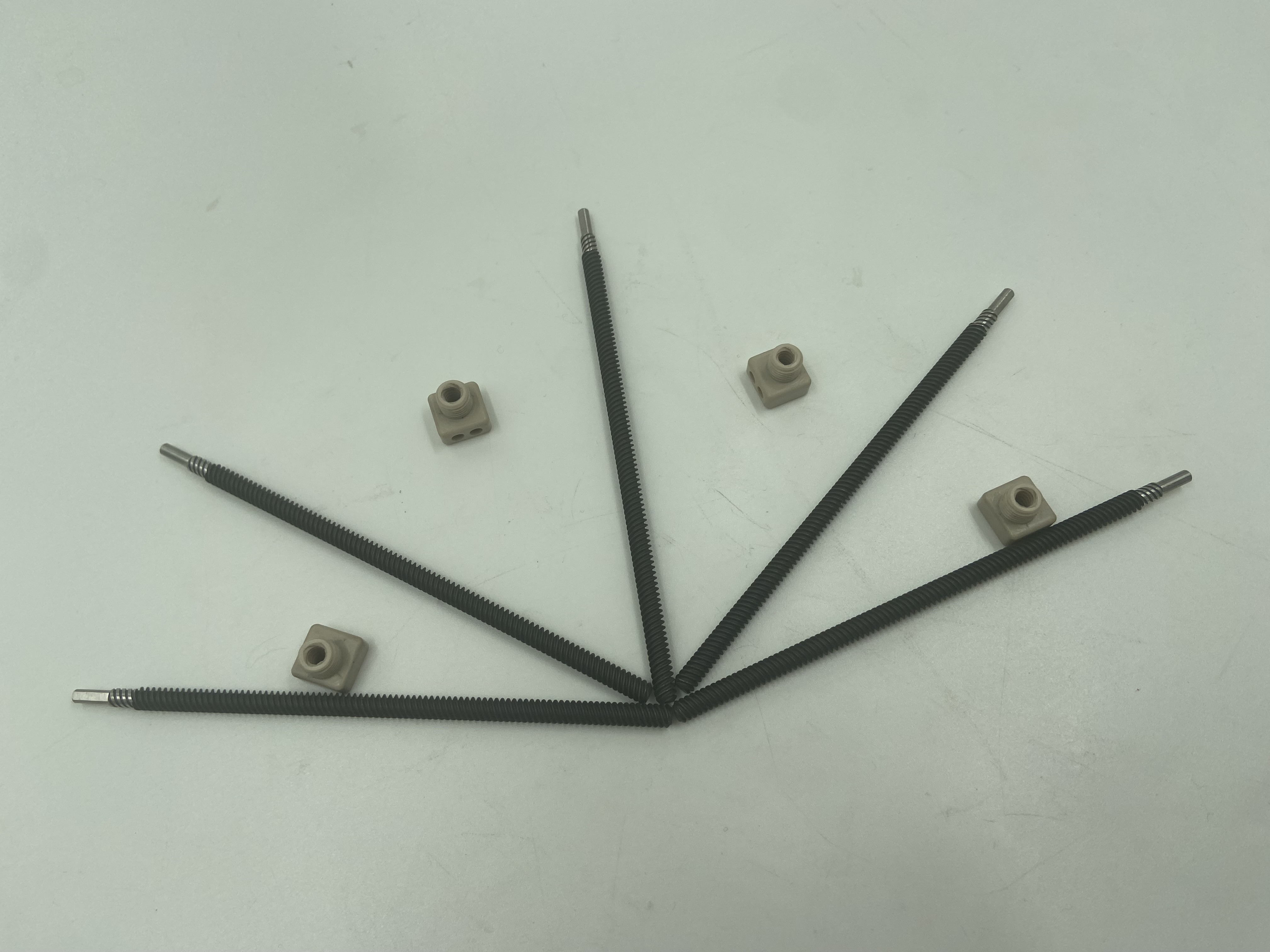

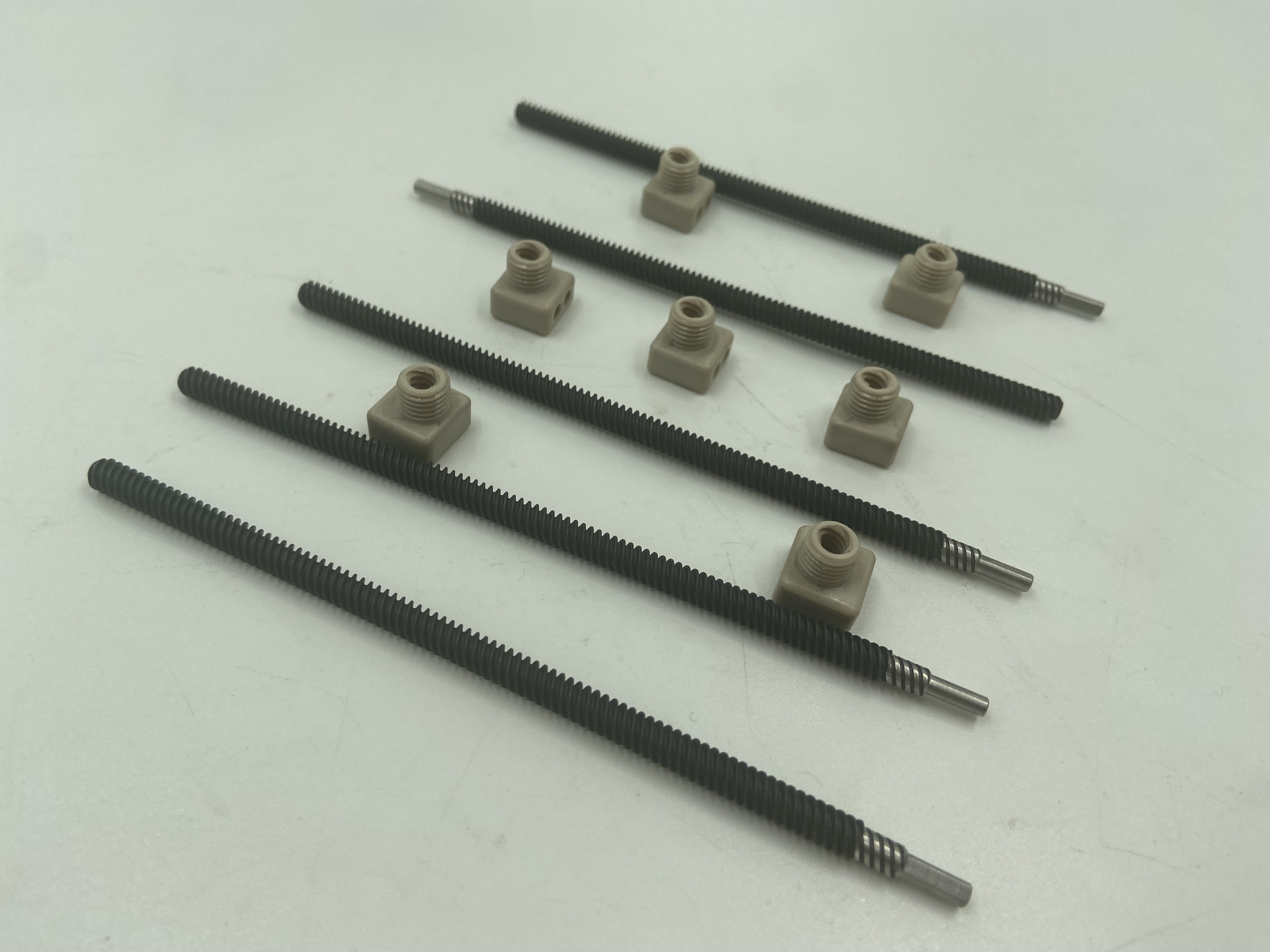

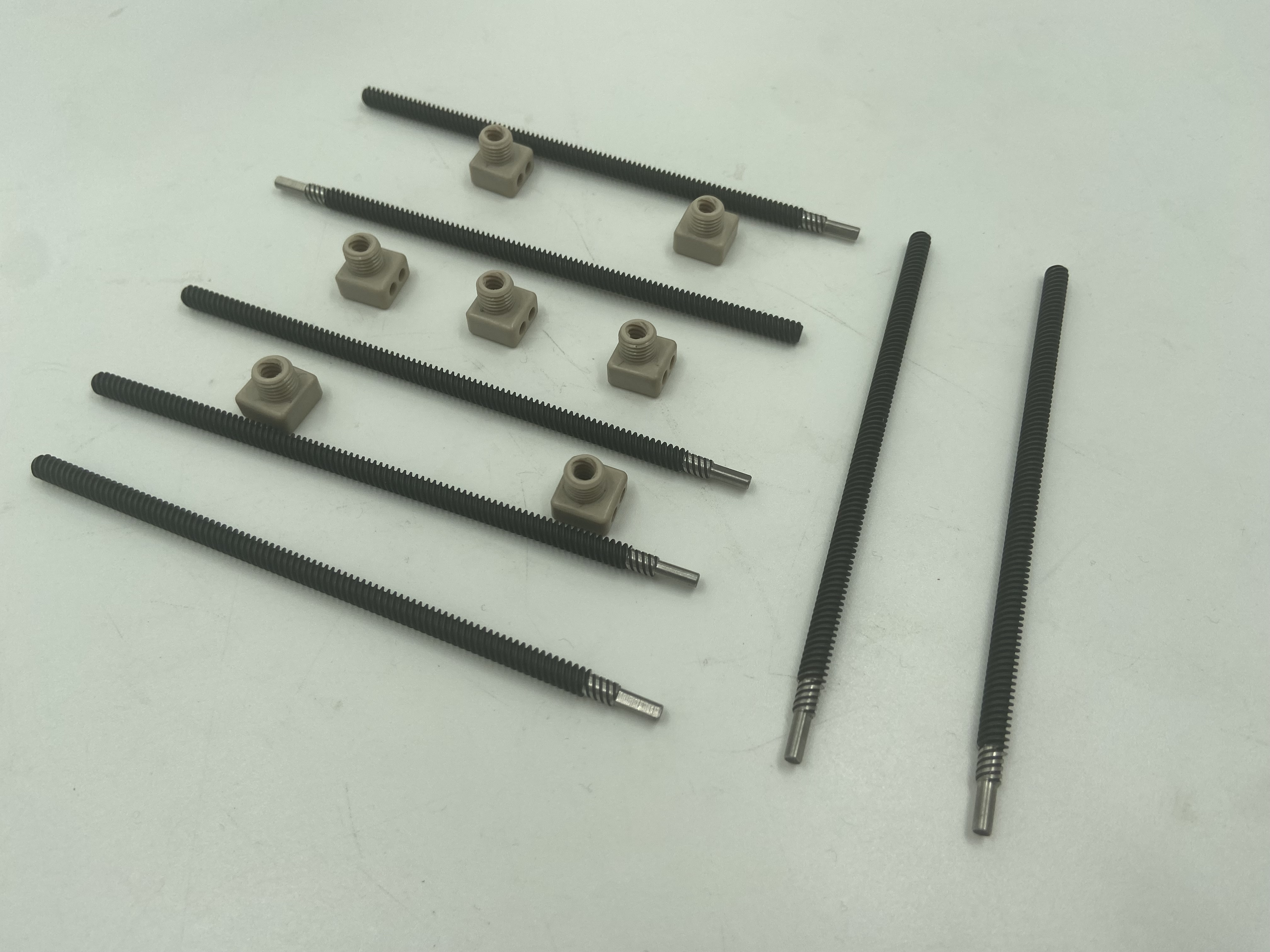

Trapezoidal lead screw is a mechanical component used for power transmission and motion,often used in industrial machinery and equipment.In order to improve the service life and performance of the trapezoidal lead screw,the surface is often coated.WS2 and MoS2 are common trapezoidal screw surface coating materials,they have some differences mainly have the following points:

(1) Material characteristics:Tungsten disulfide (WS2) is a solid lubricating material with low friction coefficient and high wear resistance,while molybdenum disulfide (MoS2) also has similar characteristics,but its friction coefficient is slightly higher.

(2) Coating color: tungsten disulfide coating is usually gray or black,while molybdenum disulfide coating is usually gray.

(3) Coating thickness:The thickness of tungsten disulfide coating is usually thinner, generally between a few microns and tens of microns,while the thickness of molybdenum disulfide coating is usually thicker, generally between tens of microns and hundreds of microns.

(4) Coating performance: Tungsten disulfide coating has lower friction coefficient and higher wear resistance, which can effectively reduce the friction loss and wear of the trapezoid lead screw and extend the service life.Molybdenum disulfide coating can also provide similar properties, but its coefficient of friction is relatively high.

(5) Application field: Because tungsten disulfide coating has lower friction coefficient and higher wear resistance,it is often used in occasions with higher friction and wear requirements,such as precision mechanical equipment,aerospace and so on.Molybdenum disulfide coating is often used in general industrial equipment and automotive and other fields.

Professional manufacturer for complete selection of lead screws - ALM (autolinearmotion.com)

Stepper Motor from China, Stepper Motor Manufacturer & Supplier - ALM (autolinearmotion.com)