- Home

- Products

- Video

- Blog

- Projects

- Quality Control

- About ALM

- News

- Support

- Contact Us

Views: 109 Author: Site Editor Publish Time: 2025-02-25 Origin: Site

Wire-wound Mayer rods and extruded Mayer rods are both used in coating applications,but they differ in their construction,performance,and suitability for specific applications.Here's the differences:

1. Wire-wound mayer rod applicators are made by winding different diameters of steel wires onto steel rods of specific diameters,and the wet film thickness is mainly controlled by the diameter of the winding wires.The coating is placed on the substrate and the wire-wound rod is scraped across the surface.The coating stored in the grooves is sheared and transferred to the substrate to form a uniform wet film.

2. Extruded wire mayer bar utilize a cold extrusion process to extrude continuous grooves of different sizes on a smooth steel rod,with the thickness of the coated wet film controlled by the size of the grooves.The material is pumped into the die slit and extruded under pressure into a uniform liquid film that directly covers the moving substrate.

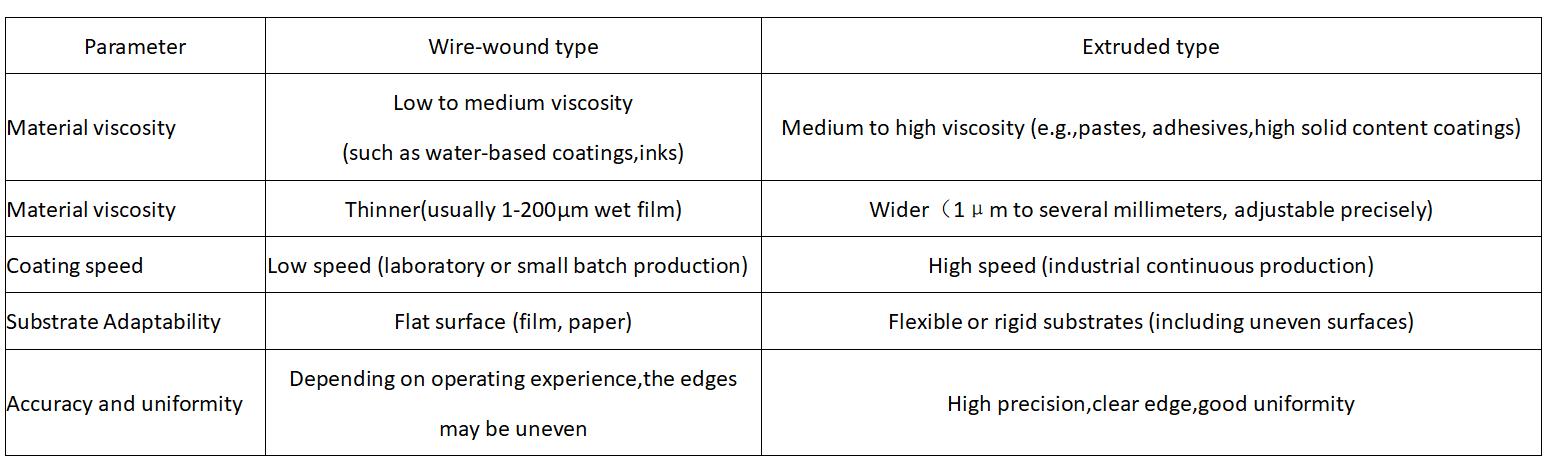

The table comparing the application scenarios of wire-wound and extrusion mayer rod coaters in 5 aspects:

(1)Winding type advantages: low cost,easy change of different wire diameter coated bar;Simple operation, suitable for laboratory or small batch test;Easy to clean and maintain.Disadvantages:poor adaptability of high viscosity material,easy residue;The coating speed is limited and the uniformity depends on manual operation.It is not possible to achieve ultra-thin or ultra-thick coatings.

(2)Extrusion type advantages: to adapt to the high viscosity materials and complex formula;Coating thickness and speed can be precisely controlled; Suitable for industrial continuous production, high efficiency.Disadvantages: high equipment cost, maintenance complex;Slit is easy to clog,need regular cleaning; Debugging parameters (pressure, speed, temperature) takes time.

ALM is a professional manufacturer of mayer rods. High precision wire coater and extruded wire coater are available, contact us to get a quote!