- Home

- Products

- Video

- Blog

- Projects

- Quality Control

- About ALM

- News

- Support

- Contact Us

Views: 174 Author: Site Editor Publish Time: 2022-12-16 Origin: Site

The ball screw contains a screw and a ballnut,the ballnut is fitted with recirculating ball bearings to carry the load.This design minimizes friction and provides high efficiency.The following are four common application standards that require ball screws(in most cases).

Many of the advantages that ball screws hold over lead screws are due to the recirculating balls that support the load.

●Heavy loads

Ball screws use recirculating steel balls to support the load and have a higher load capacity than equivalent-sized lead screws with plastic or polymer nuts.A lead screw with a bronze nut can drive a heavier load,but friction increases as the load increases.Higher friction means lower duty cycle.

Also related to load,the selection of ball screw is based on the L10 bearing life equation,providing a statistically verified estimated screw life in meters or stroke rotation.The wear characteristics of the lead screw make life almost unpredictable.A lead screw with a plastic nut can be selected based on its PV value,but this gives a range of pressures and speeds that the screw can withstand;it's not an estimate of life.

●High accuracy requirements

Unlike lead screws,which have backlash between nuts and screws,ball leads can and often are preloaded to eliminate the backlash.This is usually done by using a ball whose diameter is slightly larger than the space between the screw and nut raceway.Some lead screws offer nut designs that eliminatebacklash,but these often increase friction and reduce efficiency.In addition,ball screws have their lead deviations classified according to ISO,DIN and JIS standards,so selecting the right accuracy level for ball screws is very simple.

International standards (ISO,DIN,and JIS) define the allowable travel deviation for each ball screw accuracy class.

●High efficiency

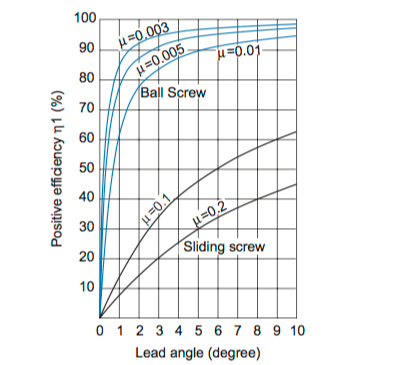

The rolling elements(e.g.,the ball in the ball screw assembly)relies on point contact to support the load,while the sliding elements(e.g.,the screws and nuts in the screw assembly)rely on line contact.Point contact creates less friction,which makes the component more efficient.An example:ball screw efficiency is almost always 90% or higher,while lead screw efficiency is usually less than 50%.High efficiency means that the required motor torque is lower,which means that smaller motors(and associated components)may be suitable for this application.

Lead angle vs.forward efficiency for various friction coefficients common to ball screws and lead screws.

●Demanding duty cycle

The maximum speed of both the lead screw and the ball screw is limited by the critical speed of the screw.However,the lower friction inherent in the ball screw design means that they generate less heat and can therefore withstand a higher duty cycle than the lead screw.In fact,when determining the amount of travel a screw will achieve over its calculated life,the duty cycle is only considered when selecting the ball screw.On the other hand,duty cycle and heat must always be considered when choosing a lead screw.As with plain linear guides with sliding friction,a lead screw with a plastic nut must adhere to its maximum PV(pressure x velocity)value.

Click to select ALM high quality ball screw for your application: