- Home

- Products

- Video

- Blog

- Projects

- Quality Control

- About ALM

- News

- Support

- Contact Us

Views: 16 Author: Site Editor Publish Time: 2022-12-08 Origin: Site

The ball spline is a linear guide rail for rolling bearings,similar to the round shaft and bushing assembly,but with key differences in its operation.The shaft of a ball spline is much like a linear guide shaft,except that the spline shaft has grooves along its length.Spline nuts(bearings or bushings similar to traditional rolling bearing rails)contain recirculating balls.However,instead of the spline nut traveling freely on the shaft and being able to rotate as it travels,the bearing ball travels in the shaft slot,which limits the rotating of the spline nut.

A ball spline incorporates grooves along the length of the shaft and on the inner surface of the spline nut to prevent rotation and transmit torque.

Another version of the ball spline is the rotary ball spline,which contains a rotating element in the outer diameter of the nut,such as an angular contact ball bearing,a cross roller,or a gear tooth.This increases the rotational motion capability of the linear motion provided by the ball spline-somewhat like the cross between the recirculating linear guide and theball screw.

A rotary ball spline can incorporate angular contact bearings(shown),crossed rollers,or gears to produce rotary motion.

Because the recirculating ball of the spline nut travels in the groove,the contact area is larger than the ball bushing,so the load capacity of the ball spline is much higher than that of a ball bushing assembly of the same size.But while higher load capacity is a benefit,the main reason many designers and engineers use ball splines is their ability to prevent rotation,or in the case of rotating ball splines,to provide both linear and rotational motion in one device.

One shaft takes the place of two

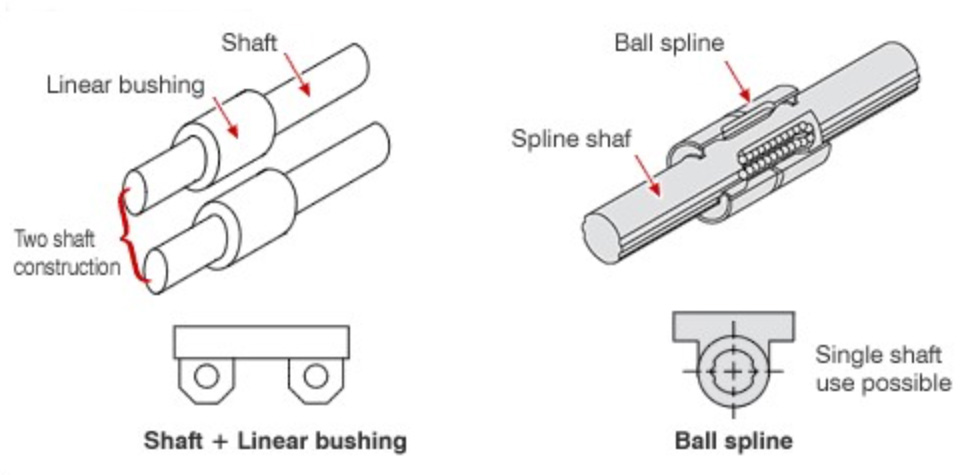

Conventional linear bushings are used almost exclusively in dual-shaft configurations to prevent the bearing from spinning while driving on the shaft.But because spherical splines are inherently anti-rotation,they can be used in a single-shaft configuration.Replacing two shafts with one also means a smaller footprint,lighter weight and easier alignment and assembly.

In this example,the ball spline is used for paper making applications.The scroll requires the degree of freedom to move horizontally from left to right,but not rotate.To prevent rotation,two conventional linear shafts are needed,but a single spline shaft supports the load,allowing horizontal movement while preventing rotation.

Ball spline used for paper making applications

Linear and rotary motion in one

The spinner spline also provides an excellent solution for the Z-theta axis on the robot.The spline shaft provides Z(vertical)motion and the rotary bearing on the spline nut provides θ(rotational) motion.These characteristics also make the rotary ball spline suitable for automatic tool changing devices in CNC machine tools.

In this automatic tool changer,a rotary ball spline provides both rotary and linear motion.

Pick and place or assemble applications can also benefit from rotating ball splines.For example,moving parts from one workstation or conveyor belt to another might involve picking up parts from the first conveyor belt(vertical motion),rotating to the position of the second conveyor belt(rotational motion),and placing parts on the second conveyor belt(vertical motion).In this case,the spinning ball spline can be driven by a combination of a cylinder for linear motion and a belt and pulley system for rotary motion.

In this pick and place application,the spinning ball spline is driven by apneumatic cylinder for linear motion and by a belt and pulley system for rotary motion.

https://www.autolinearmotion.com/ball-splines.html