- Home

- Products

- Video

- Blog

- Projects

- Quality Control

- About ALM

- News

- Support

- Contact Us

Views: 97 Author: Site Editor Publish Time: 2023-03-13 Origin: Site

Rack and pinions are often the preferred drive option for applications requiring long stroke.For ball screw drives,the critical speed of the ball screw(the speed at which the ball screw begins to whip as it rotates)is proportional to the diameter of the ball screw and inversely proportional to the square of its unsupported length.Therefore,for long stroke at even moderate speeds,the ball screw diameter needs to be relatively large to prevent ball screw whip.Rack and pinion drives,on the other hand,can be manufactured to almost infinite lengths by mounting rack sections end-to-end without increasing the module(size)of the rack or larger opinion.

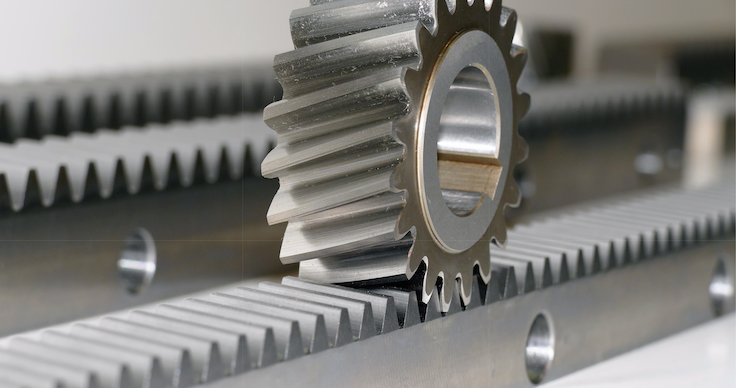

A rack with a helical pinion.

In addition,for ball screw drives,the inertia that the load must control increases as the stroke length increases.At long stroke lengths,this inertia can be significant.For ball screws,a longer stroke length usually means an increase in both the length and diameter of the ball screw,resulting in a significant increase in mass and inertia.The higher the inertia of the moving load,the more difficult it is to achieve dynamic motions -- especially those that require high thrust at high accelerations.

Various ball screws from ALM company

On the other hand,one of the main advantages of rack and pinion systems is that their moved inertia does not increase with length,so they can achieve high speed and high dynamic moves regardless of stroke length.

Although ball screw is generally considered the most accurate of the two drive mechanisms,rack and pinion systems can provide accuracy and repeatability that approaches or even exceeds most typical ball screw applications.According to DIN/ISO and AGMA quality standards,rack with helical teeth may have a pitch error in the single micron range,with cumulative pitch errors of less than 25 microns per meter.Preload rack and pinion systems eliminate backlash and achieve excellent repeatability,especially when applications require directional changes.

Click to select ALM high quality linear motion components for your application: