- Home

- Products

- Video

- Blog

- Projects

- Quality Control

- About ALM

- News

- Support

- Contact Us

| Availability: | |

|---|---|

| Quantity: | |

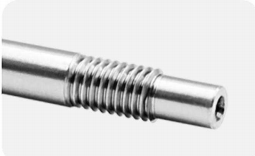

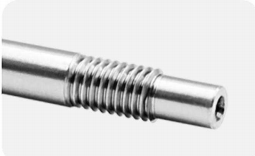

T12x2

ALM

8483900090

The T12x2 lead screw has low backlash.This results in accurate and repeatable positioning.The T12x2 lead screw is made of high-quality materials and is designed to last for a long time.This makes it a cost-effective solution for many applications.

| ALM Lead Screw Basic Information | |

| Lead screw material | ASTM1045,SUS303,SUS304,SS316,SS316L |

Lead nut material | Brass,Tin bronze,Phosphor bronze,Aluminum bronze,POM,PEEK,nylon,POK,Stainless steel, 1045,Zinc alloy,Brass+Plastic,Aluminum alloy+Plastic,Brass+Steel,Self lubricating(No oil type) |

Available surface coating | Zinc-plated,nickel plated,hard chromium plated,fluorine coated,tungsten disulfide,black chorme plated |

| Quality standard | ISO9001:2015,CE certificate,RoHS and reach compliance |

| Clearance | 7e,higher precision is available upon request |

| Custom Services | Customized nuts and end machining are available upon drawing |

For more information,pls contact the salesman.

| ALM Lead Screw Factory |

| Lead Screw Shaft End Machining |

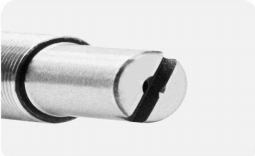

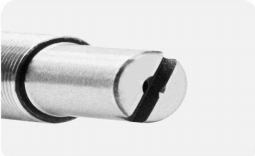

ALM provides lead screw shaft end machining custom services,the following is the common shaft end machining drawing,other lead screw shaft end machining according to customer requirements.

Milling Circlip

Milling Slotted Drives

Milling Hex Socket

Milling Flat

| Lead Screw and Lead Nut Materials |

ALM provides a variety of lead screw and lead nut materials for your selection.You can also contact us,we will give you professional advice according to your specific application.

●plastic materials

●metal materials

| Our Advantages |

| Free service | Performance testing |

| Technical solution | |

| Please contact the salesman for details | |

Custom service | C45,Stainless steel and other customized materials |

| Surface treatment | |

| Custom lead nut and shaft end machining | |

| Please contact the salesman for details | |

| Lead Screw Shipping and Payment |

●Shipping

Sample order:We have DHL,FedEx,UPS VIP account with discount.So you can get favorable shipping freight.

Bulk order:We have freight forwarder to ship by air,by train or by sea.You can also arrange shipping through your own agent.

●Payment

LC,T/T,D/P,PayPal,Western Union,Money Gram

| ALM Lead Screw Catalog Download |

A broad range of lead nuts are available,other nut type or size can be made upon drawing.Other lead screw models are available,kindly pls refer to the catalog.Lead screw catalog-ALM.pdf

The T12x2 lead screw has low backlash.This results in accurate and repeatable positioning.The T12x2 lead screw is made of high-quality materials and is designed to last for a long time.This makes it a cost-effective solution for many applications.

| ALM Lead Screw Basic Information | |

| Lead screw material | ASTM1045,SUS303,SUS304,SS316,SS316L |

Lead nut material | Brass,Tin bronze,Phosphor bronze,Aluminum bronze,POM,PEEK,nylon,POK,Stainless steel, 1045,Zinc alloy,Brass+Plastic,Aluminum alloy+Plastic,Brass+Steel,Self lubricating(No oil type) |

Available surface coating | Zinc-plated,nickel plated,hard chromium plated,fluorine coated,tungsten disulfide,black chorme plated |

| Quality standard | ISO9001:2015,CE certificate,RoHS and reach compliance |

| Clearance | 7e,higher precision is available upon request |

| Custom Services | Customized nuts and end machining are available upon drawing |

For more information,pls contact the salesman.

| ALM Lead Screw Factory |

| Lead Screw Shaft End Machining |

ALM provides lead screw shaft end machining custom services,the following is the common shaft end machining drawing,other lead screw shaft end machining according to customer requirements.

Milling Circlip

Milling Slotted Drives

Milling Hex Socket

Milling Flat

| Lead Screw and Lead Nut Materials |

ALM provides a variety of lead screw and lead nut materials for your selection.You can also contact us,we will give you professional advice according to your specific application.

●plastic materials

●metal materials

| Our Advantages |

| Free service | Performance testing |

| Technical solution | |

| Please contact the salesman for details | |

Custom service | C45,Stainless steel and other customized materials |

| Surface treatment | |

| Custom lead nut and shaft end machining | |

| Please contact the salesman for details | |

| Lead Screw Shipping and Payment |

●Shipping

Sample order:We have DHL,FedEx,UPS VIP account with discount.So you can get favorable shipping freight.

Bulk order:We have freight forwarder to ship by air,by train or by sea.You can also arrange shipping through your own agent.

●Payment

LC,T/T,D/P,PayPal,Western Union,Money Gram

| ALM Lead Screw Catalog Download |

A broad range of lead nuts are available,other nut type or size can be made upon drawing.Other lead screw models are available,kindly pls refer to the catalog.Lead screw catalog-ALM.pdf

ALM originally established in year of 2005.From a small factory,ALM nowadays has four production workshops for ball screw,lead screw,linear motor,linear actuator,linear guideways and related CNC machining parts for automation industry.Total areas over 7000 square meters,109 employees.Above 8 technical engineers are with over 20 years’ experience in linear motion filed.

ALM manufactures and supplies high quality linear motion components for customers in fields of aircraft, satellite,medical,Instrumentation,Robotics,Automobile,Electrical & Electronics,Textile,Medical,Food & Beverages,General Industry and so on.Customers cover more than 65 countries in Europe,North America,South Asia,Middle East,Africa,Latin America etc.With super quality and service,ALM has been widely recognized and highly valued by its high-end and picky customers, and thus remains at the top of their vendor lists.

ALM key production machines are imported,like high precision CNC grinding machine,3 axis,4 axis machining centre,internal and external grinding centre,CNC lathe.In addition,with advanced production management,ALM obtained the quality certificate ISO9001:2008 and IATF16949.And through our R&D department dedication over 16 years,we possess more than 26 national patents.

ALM's office

ALM's workshop

ALM product processing

ALM's warehouse

ALM product show

Customer Visit

ALM originally established in year of 2005.From a small factory,ALM nowadays has four production workshops for ball screw,lead screw,linear motor,linear actuator,linear guideways and related CNC machining parts for automation industry.Total areas over 7000 square meters,109 employees.Above 8 technical engineers are with over 20 years’ experience in linear motion filed.

ALM manufactures and supplies high quality linear motion components for customers in fields of aircraft, satellite,medical,Instrumentation,Robotics,Automobile,Electrical & Electronics,Textile,Medical,Food & Beverages,General Industry and so on.Customers cover more than 65 countries in Europe,North America,South Asia,Middle East,Africa,Latin America etc.With super quality and service,ALM has been widely recognized and highly valued by its high-end and picky customers, and thus remains at the top of their vendor lists.

ALM key production machines are imported,like high precision CNC grinding machine,3 axis,4 axis machining centre,internal and external grinding centre,CNC lathe.In addition,with advanced production management,ALM obtained the quality certificate ISO9001:2008 and IATF16949.And through our R&D department dedication over 16 years,we possess more than 26 national patents.

ALM's office

ALM's workshop

ALM product processing

ALM's warehouse

ALM product show

Customer Visit

Patent Certificate for invention and utility model

ISO Certificate

CE Certificate

Excellent HighTech Enterprise

Leading Talents Certificate

Patent Certificate for invention and utility model

ISO Certificate

CE Certificate

Excellent HighTech Enterprise

Leading Talents Certificate

1.Why can ALM be your better option for linear motion components?

With more than 16 years of industry experience,quality assurance,factory directly price.

2.What is your main products ?

Our Main products are consist of ball screw,linear guide,lead screw,linear module and linear motor.

3.How to Custom-made?

Step1:Send us your drawing for checking.We will check the production feasibility.Our specially trained engineers will help you find out the best solution based on rich projects experience.

Step2:We make our production drawing for your checking to avoid misunderstanding.And to ensure each dimensions comply with your requirements.

Step3:Prepare for sample

Step4:After samples approved on your prototype.Move to mass production

4.When can I get the quotation?

We usually quote within 24 hours after we get your inquiry.If you are very urgent to get the price,please call us or tell us in your email so that we will regard your inquiry priority.

1.Why can ALM be your better option for linear motion components?

With more than 16 years of industry experience,quality assurance,factory directly price.

2.What is your main products ?

Our Main products are consist of ball screw,linear guide,lead screw,linear module and linear motor.

3.How to Custom-made?

Step1:Send us your drawing for checking.We will check the production feasibility.Our specially trained engineers will help you find out the best solution based on rich projects experience.

Step2:We make our production drawing for your checking to avoid misunderstanding.And to ensure each dimensions comply with your requirements.

Step3:Prepare for sample

Step4:After samples approved on your prototype.Move to mass production

4.When can I get the quotation?

We usually quote within 24 hours after we get your inquiry.If you are very urgent to get the price,please call us or tell us in your email so that we will regard your inquiry priority.