- Home

- Products

- Video

- Blog

- Projects

- Quality Control

- About ALM

- News

- Support

- Contact Us

Industrial belt is a kind of transmission device widely used in various industrial fields.They are made of soft materials,usually synthetic materials such as rubber,polyurethane or nylon.The main function of the industrial belt is to transfer power from one rotating shaft to another rotating shaft,so as to achieve the operation of mechanical equipment.

ALM focuses on providing professional belt solutions for industrial automation

●ALM Belt category

Synchronous Belts

V-Belts

Banded Belts

Specialty Belts

Ribbed belt

Agricultural Belts

Powersport Belts

Automotive belt

●Industry Solution Case

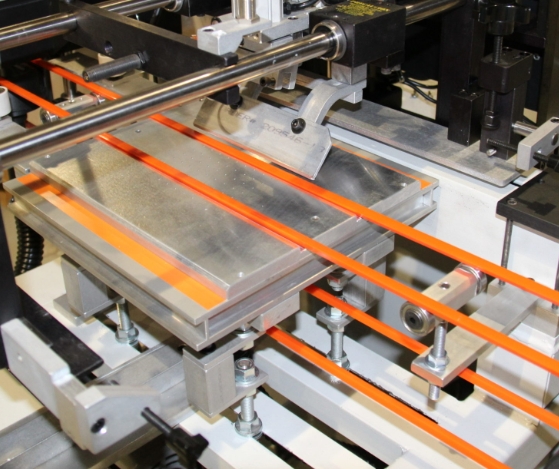

Industrial belts are widely used in many different industries and applications.For example,belts are used in the automotive manufacturing industry for drivetrains that transmit power from the engine to the wheels.In the logistics and transportation industry,industrial belts are used in conveyor belt systems to help move items along the production line.In addition,industrial belts are also used in various equipment in mining, metallurgy, chemical and food processing industries.

Food production and processing

Assembly line, logistics transportation

Stone,porcelain production and processing

Packaging and printing industries

Wood,wood-based panel production

Automobile,tire industry

Fitness,entertainment industry

Tobacco industry transportation

●Belt Drive Advantages

(1)Transmit large torque: belt drive can transmit large torque,suitable for industrial equipment that needs to transmit high power.Compared to other transmission methods,such as gear drive,belt drive can be better adapted to torque changes and impact loads.

(2)Space saving:belt drive can achieve transmission in a small space, suitable for industrial equipment with limited space.Compared with transmission methods such as gear drive,belt drive can better meet the requirements of compact design.

(3)Buffer and shock absorption:belt drive can play a role in buffer and shock absorption,reducing the impact load in the transmission process.This is important for industrial equipment that requires protection and extended service life.

(4)Speed regulation and speed change:the belt drive can realize the function of speed regulation and speed change by changing the tension of the belt,which is suitable for industrial equipment that needs to be adjusted frequently according to the process requirements.

(5)Low maintenance cost: Compared with other transmission methods,the maintenance cost of belt drive is lower. When the belt is worn or damaged,only the belt needs to be replaced,without the need for large-scale repair or replacement of the entire transmission system.