- Home

- Products

- Video

- Blog

- Projects

- Quality Control

- About ALM

- News

- Support

- Contact Us

| Availability: | |

|---|---|

| Quantity: | |

1001

ALM

8483900090

The 1001 bi-directional ball screw consists of a ball screw shaft with a left and right thread and two ballnuts.This is a good choice when you need to move two ballnuts in opposite directions through a motor.Our commonly used material of ball screw is bearing steel,the ball screw axial play can be zero and can achieve 90% efficiency.The accuracy grade of our bi-directional ball screw can be C1,C3,C5.

| Material | Gcr15(HRC60~62),9Cr18(HRC55~58) |

| Axial play | 0~0.005mm(Can be zero) |

| Preload | P0,P1,P2,P3,P4 |

| Efficiency | >90% |

| Accuracy grade | C1,C3,C5 |

| Features | Clean and smooth,excellent surface finsh |

| Certificates | ISO9001:2015,CE certificate,RoHS and reach compliance |

| MOQ | 1 piece |

| Lead time | 10~30 days. |

| Packing | Carton+Plastic bag + Wooden box or according to customers' demands |

| Mating parts | Nut housing,ball screw support BK,BF,EK,EF,FK,FF,end maching service is available |

Notes:Other model or ballnut types are available upon your requirement.

| ALM Ball Screw Video Show |

| Our Advantages |

| Free service | Performance testing |

| Technical solution | |

| Please contact the salesman for details | |

| Custom service | Gcr15,9Cr18 and other customized materials |

| Surface treatment | |

| Custom ballnut and shaft end machining | |

| Assembly | |

| Please contact the salesman for details | |

| Ball Screw Dimension |

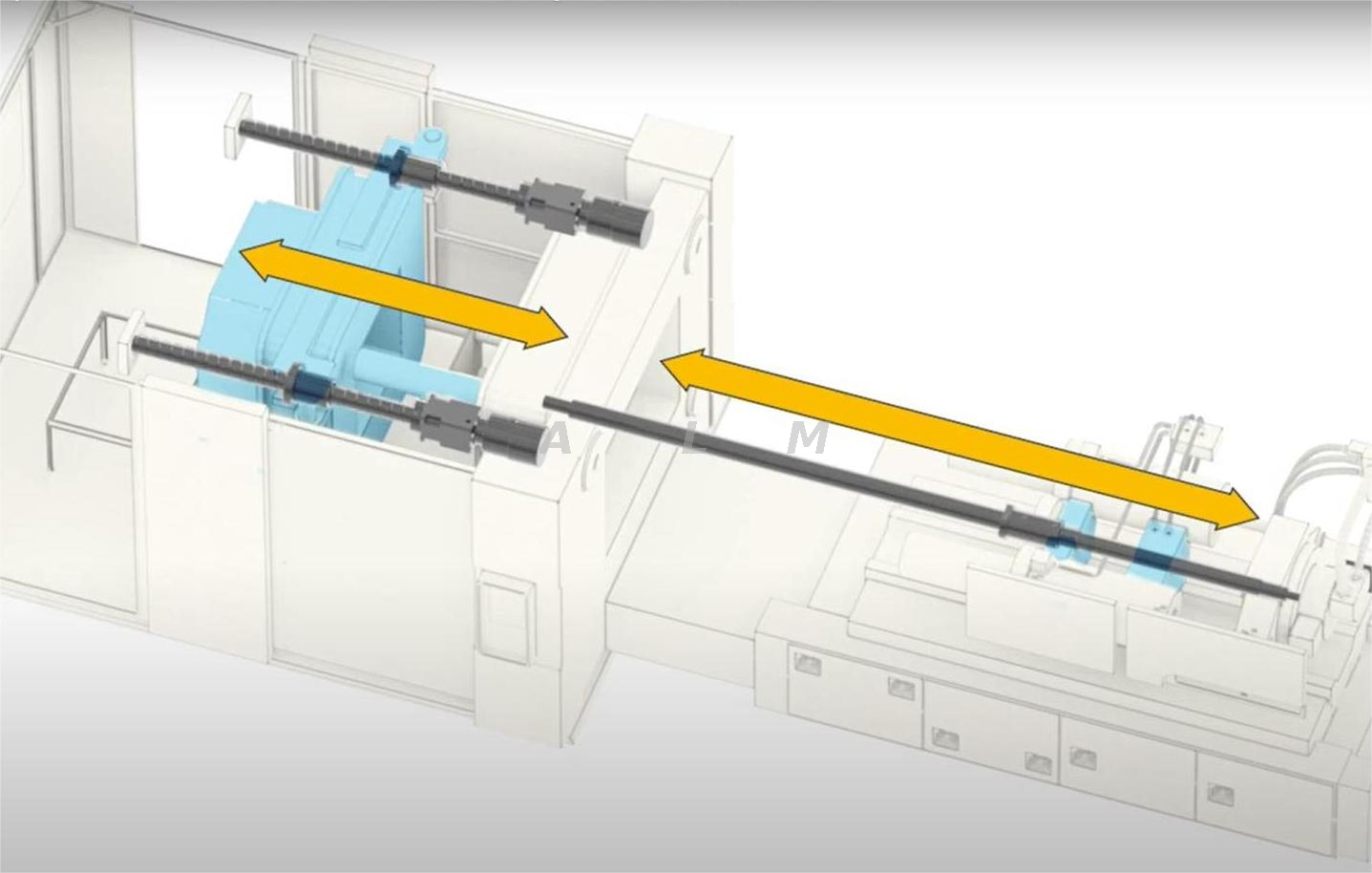

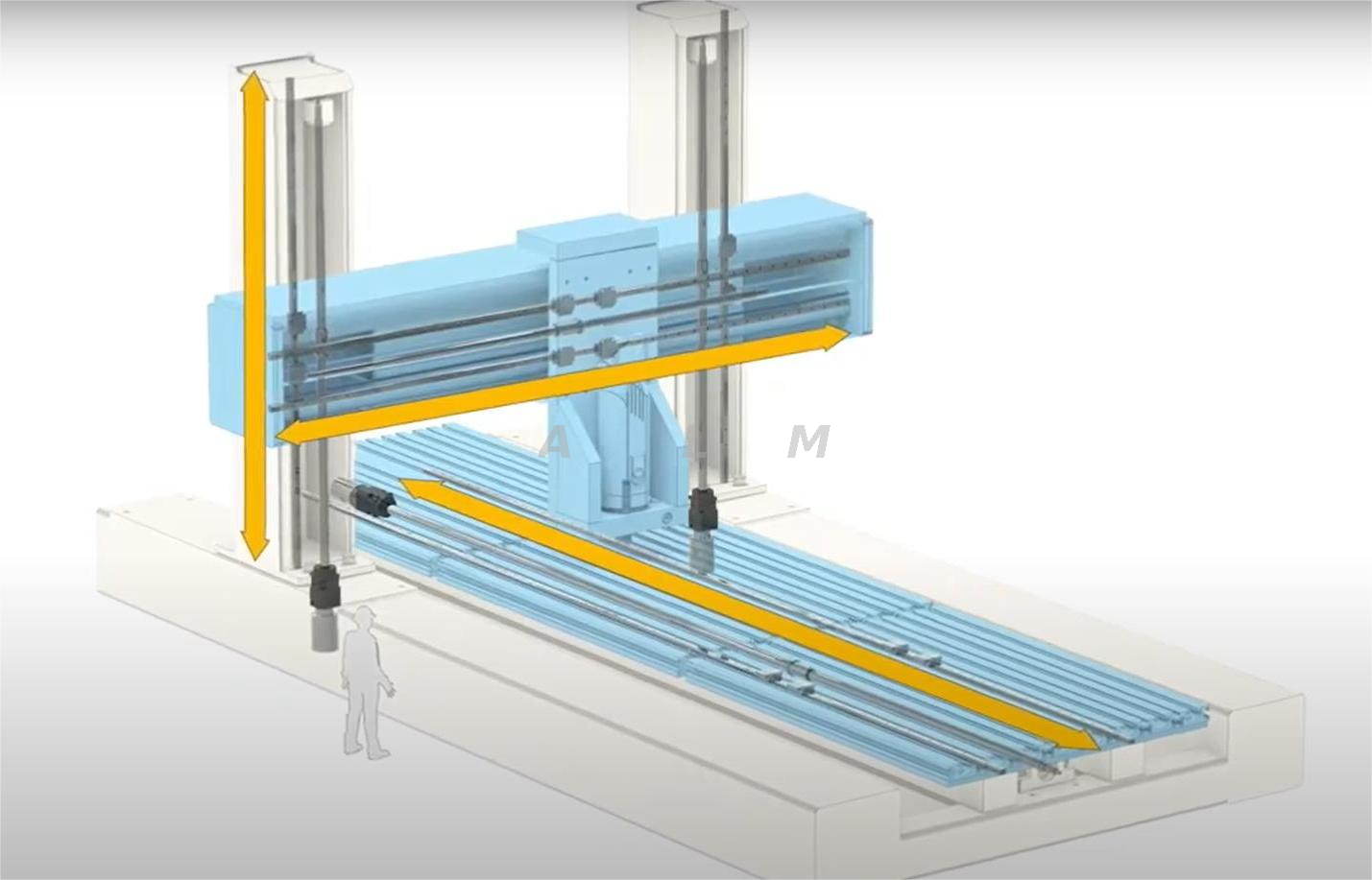

| Ball Screw Application |

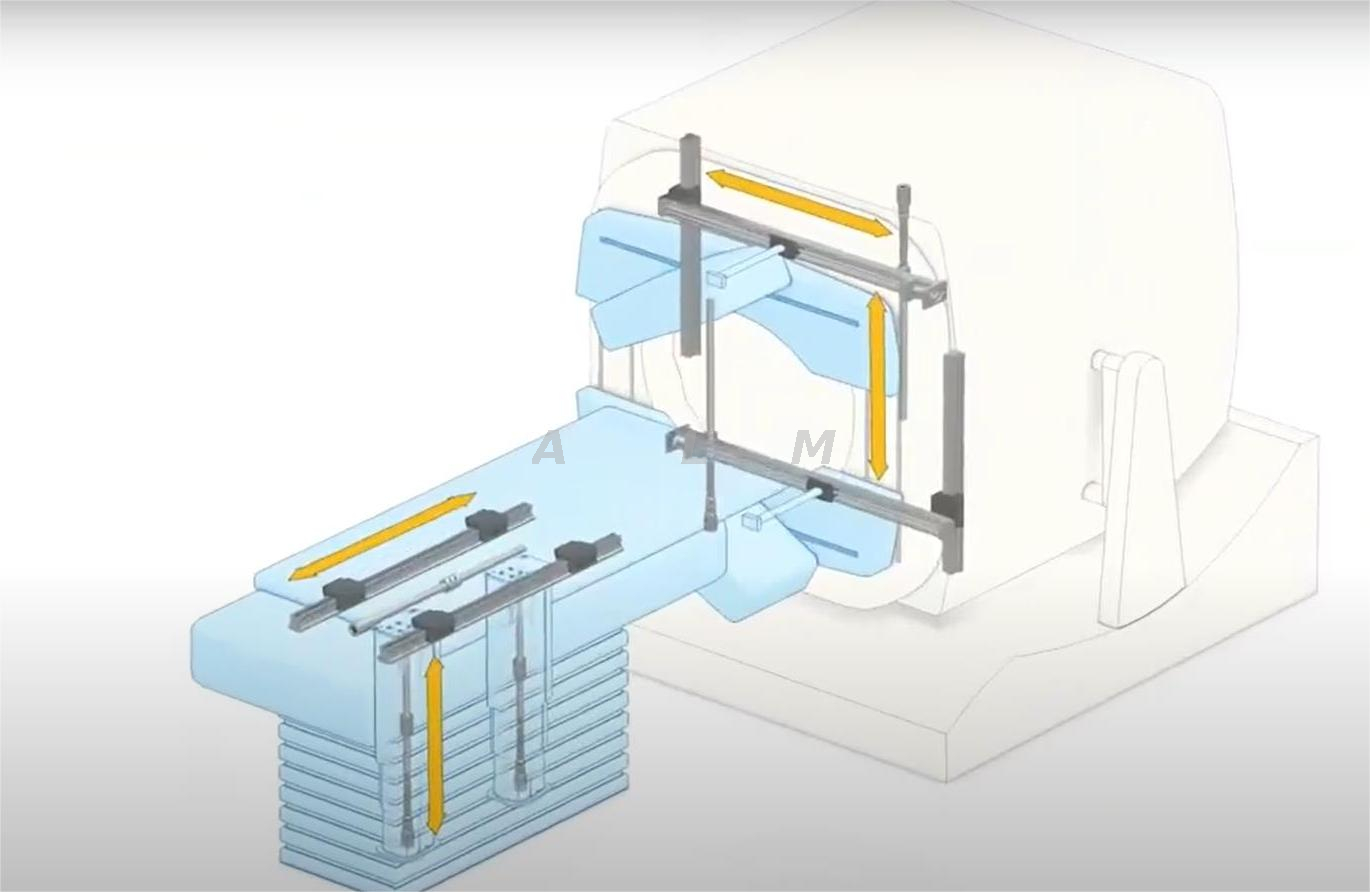

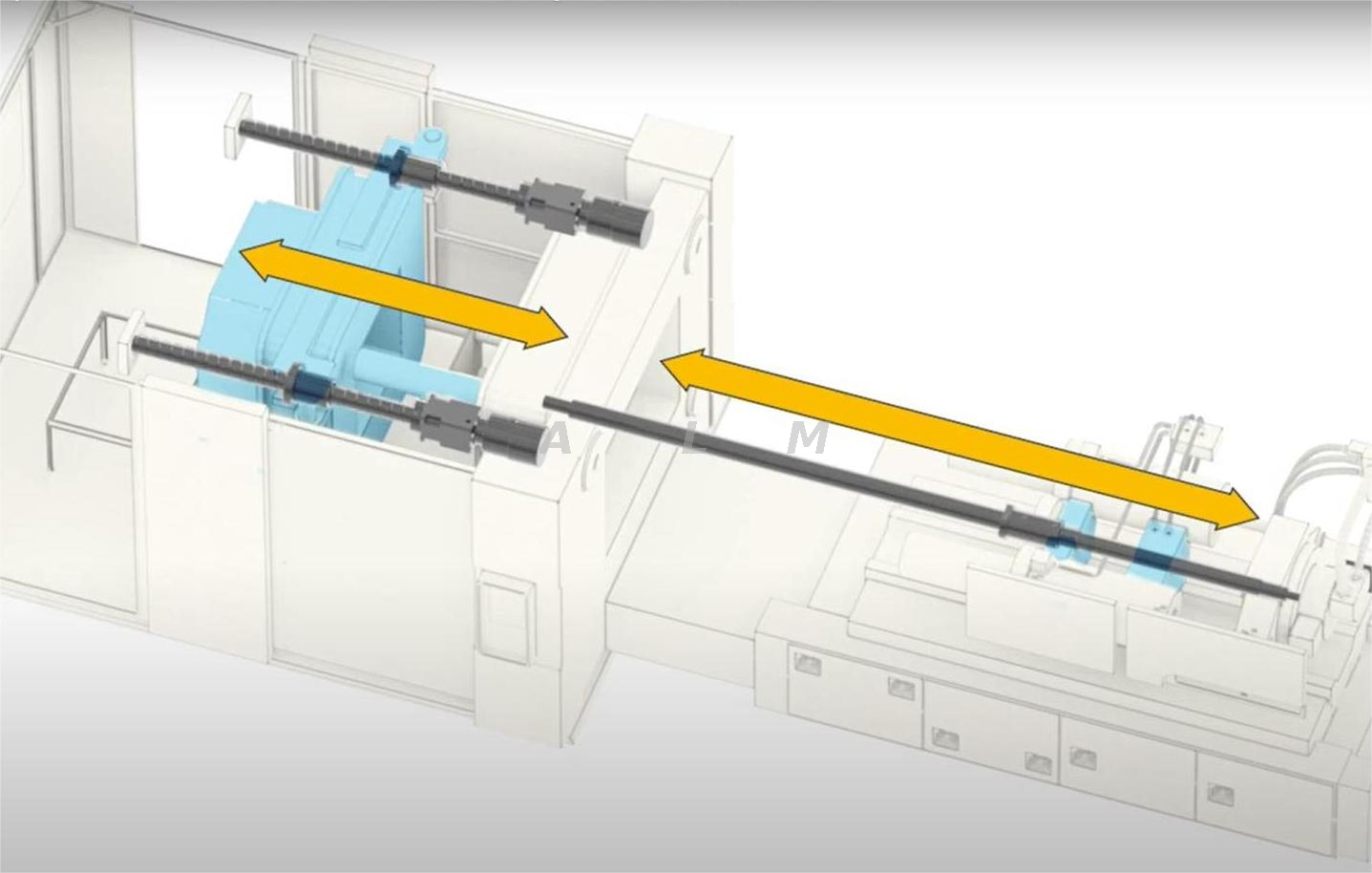

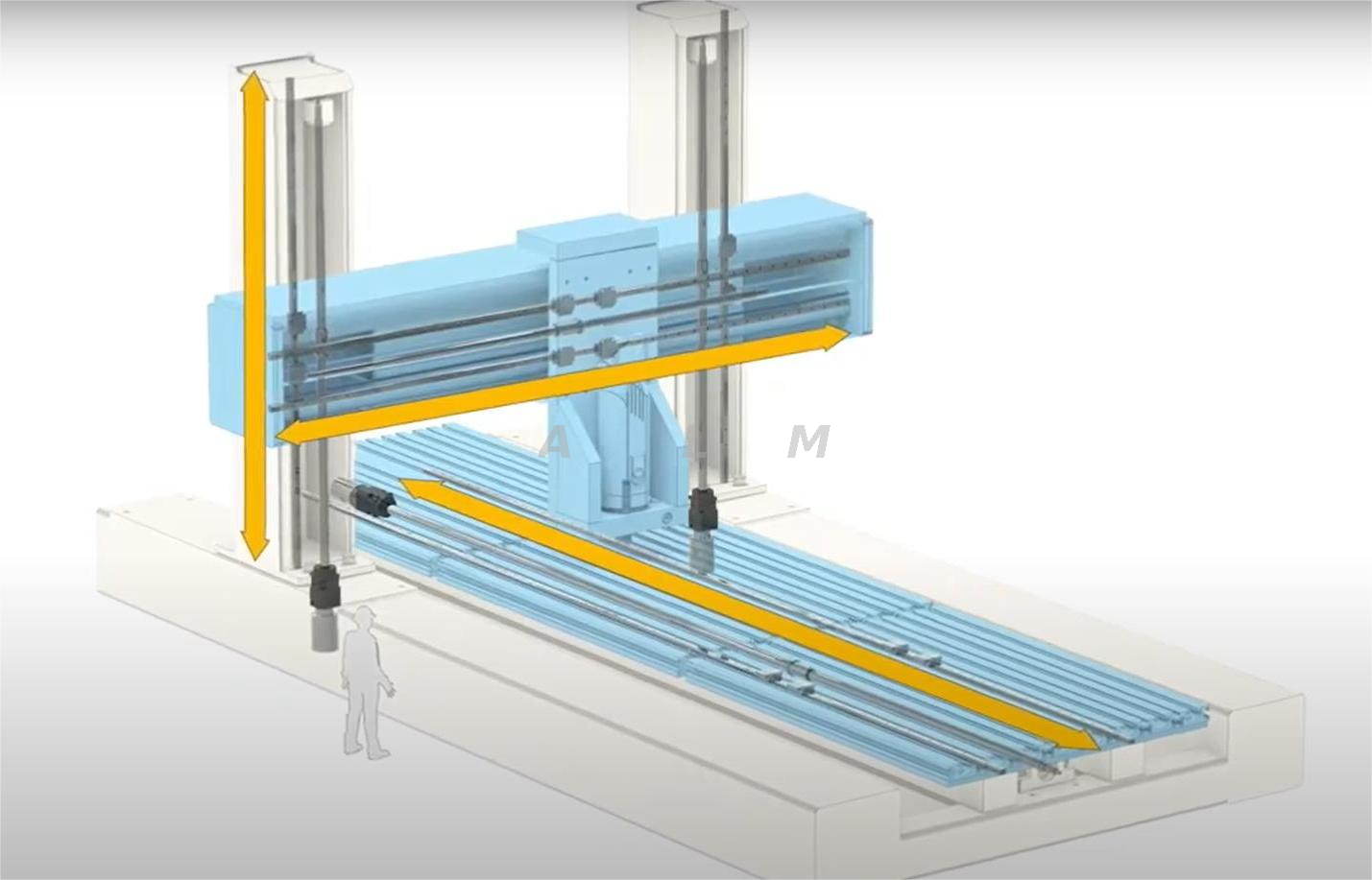

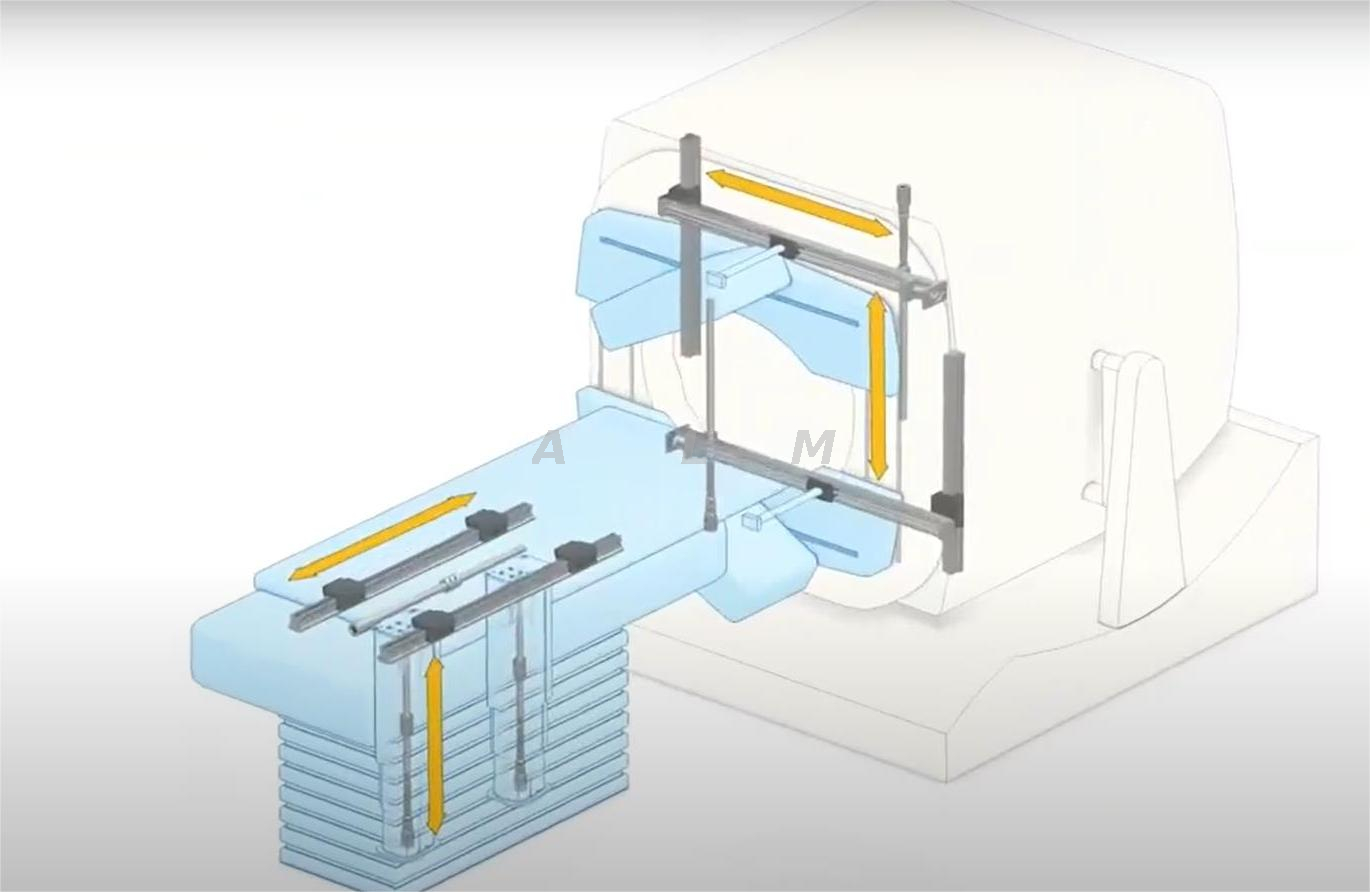

ALM ball screws are used in various applications where precise linear motion,high speed,and high accuracy are required.Our ball screws provide a reliable and efficient solution for many industrial and commercial applications.The following pictures show the common application of our ball screw.

Medical device

Solar pannel

Packging and injection mold

Woodworking machine

Machine centre

| Ball Screw Shipping and Payment |

●Shipping

Sample order:We have DHL,FedEx,UPS VIP account with discount.So you can get favorable shipping freight.

Bulk order:We have freight forwarder to ship by air,by train or by sea.You can also arrange shipping through your own agent.

●Payment

LC,T/T,D/P,PayPal,Western Union,Money Gram

| Bi-directional Ball Screw Catalog Download |

Other bi-directional ball screws are available,kindly please refer to the catalog below.If you don't find the ball screw you need,please email us.We can manufacture the ball screw according to your drawing.

The 1001 bi-directional ball screw consists of a ball screw shaft with a left and right thread and two ballnuts.This is a good choice when you need to move two ballnuts in opposite directions through a motor.Our commonly used material of ball screw is bearing steel,the ball screw axial play can be zero and can achieve 90% efficiency.The accuracy grade of our bi-directional ball screw can be C1,C3,C5.

| Material | Gcr15(HRC60~62),9Cr18(HRC55~58) |

| Axial play | 0~0.005mm(Can be zero) |

| Preload | P0,P1,P2,P3,P4 |

| Efficiency | >90% |

| Accuracy grade | C1,C3,C5 |

| Features | Clean and smooth,excellent surface finsh |

| Certificates | ISO9001:2015,CE certificate,RoHS and reach compliance |

| MOQ | 1 piece |

| Lead time | 10~30 days. |

| Packing | Carton+Plastic bag + Wooden box or according to customers' demands |

| Mating parts | Nut housing,ball screw support BK,BF,EK,EF,FK,FF,end maching service is available |

Notes:Other model or ballnut types are available upon your requirement.

| ALM Ball Screw Video Show |

| Our Advantages |

| Free service | Performance testing |

| Technical solution | |

| Please contact the salesman for details | |

| Custom service | Gcr15,9Cr18 and other customized materials |

| Surface treatment | |

| Custom ballnut and shaft end machining | |

| Assembly | |

| Please contact the salesman for details | |

| Ball Screw Dimension |

| Ball Screw Application |

ALM ball screws are used in various applications where precise linear motion,high speed,and high accuracy are required.Our ball screws provide a reliable and efficient solution for many industrial and commercial applications.The following pictures show the common application of our ball screw.

Medical device

Solar pannel

Packging and injection mold

Woodworking machine

Machine centre

| Ball Screw Shipping and Payment |

●Shipping

Sample order:We have DHL,FedEx,UPS VIP account with discount.So you can get favorable shipping freight.

Bulk order:We have freight forwarder to ship by air,by train or by sea.You can also arrange shipping through your own agent.

●Payment

LC,T/T,D/P,PayPal,Western Union,Money Gram

| Bi-directional Ball Screw Catalog Download |

Other bi-directional ball screws are available,kindly please refer to the catalog below.If you don't find the ball screw you need,please email us.We can manufacture the ball screw according to your drawing.

ALM originally established in year of 2005.From a small factory,ALM nowadays has four production workshops for ball screw,lead screw,linear motor,linear actuator,linear guideways and related CNC machining parts for automation industry.Total areas over 7000 square meters,109 employees.Above 8 technical engineers are with over 20 years’ experience in linear motion filed.

ALM manufactures and supplies high quality linear motion components for customers in fields of aircraft, satellite,medical,Instrumentation,Robotics,Automobile,Electrical & Electronics,Textile,Medical,Food & Beverages,General Industry and so on.Customers cover more than 65 countries in Europe,North America,South Asia,Middle East,Africa,Latin America etc.With super quality and service,ALM has been widely recognized and highly valued by its high-end and picky customers, and thus remains at the top of their vendor lists.

ALM key production machines are imported,like high precision CNC grinding machine,3 axis,4 axis machining centre,internal and external grinding centre,CNC lathe.In addition,with advanced production management,ALM obtained the quality certificate ISO9001:2008 and IATF16949.And through our R&D department dedication over 16 years,we possess more than 26 national patents.

ALM's office

ALM's workshop

ALM product processing

ALM's warehouse

ALM product show

Customer Visit

ALM originally established in year of 2005.From a small factory,ALM nowadays has four production workshops for ball screw,lead screw,linear motor,linear actuator,linear guideways and related CNC machining parts for automation industry.Total areas over 7000 square meters,109 employees.Above 8 technical engineers are with over 20 years’ experience in linear motion filed.

ALM manufactures and supplies high quality linear motion components for customers in fields of aircraft, satellite,medical,Instrumentation,Robotics,Automobile,Electrical & Electronics,Textile,Medical,Food & Beverages,General Industry and so on.Customers cover more than 65 countries in Europe,North America,South Asia,Middle East,Africa,Latin America etc.With super quality and service,ALM has been widely recognized and highly valued by its high-end and picky customers, and thus remains at the top of their vendor lists.

ALM key production machines are imported,like high precision CNC grinding machine,3 axis,4 axis machining centre,internal and external grinding centre,CNC lathe.In addition,with advanced production management,ALM obtained the quality certificate ISO9001:2008 and IATF16949.And through our R&D department dedication over 16 years,we possess more than 26 national patents.

ALM's office

ALM's workshop

ALM product processing

ALM's warehouse

ALM product show

Customer Visit

Patent Certificate for invention and utility model

ISO Certificate

CE Certificate

Excellent HighTech Enterprise

Leading Talents Certificate

Patent Certificate for invention and utility model

ISO Certificate

CE Certificate

Excellent HighTech Enterprise

Leading Talents Certificate

1.Why can ALM be your better option for linear motion components?

With more than 16 years of industry experience,quality assurance,factory directly price.

2.What are your ways of payment?

LC,T/T, D/P,PayPal,Western Union,Money Gram

3.When can I get the quotation?

We usually quote within 24 hours after we get your inquiry.If you are very urgent to get the price,please call us or tell us in your email so that we will regard your inquiry priority.

4.How to Custom-made?

1.Why can ALM be your better option for linear motion components?

With more than 16 years of industry experience,quality assurance,factory directly price.

2.What are your ways of payment?

LC,T/T, D/P,PayPal,Western Union,Money Gram

3.When can I get the quotation?

We usually quote within 24 hours after we get your inquiry.If you are very urgent to get the price,please call us or tell us in your email so that we will regard your inquiry priority.

4.How to Custom-made?