- Home

- Products

- Video

- Blog

- Projects

- Quality Control

- About ALM

- News

- Support

- Contact Us

| Availability: | |

|---|---|

| Quantity: | |

ALM606A

ALM

8479909090

This linear actuator has 7000N(700kg)maximum load capacity and 900mm(0.9 meter)maximum stroke length.The actuator is waterproof and is powered by a 12V/24V/36V/48V DC electric motor,which ensures stable and durable performance under temperature from -40 to 65°C.Electric linear actuators are versatile devices that provide reliable and efficient linear motion solutions in a wide range of applications.

●ALM Linear Actuators Technical Parameters

●ALM Linear Actuators Details Show

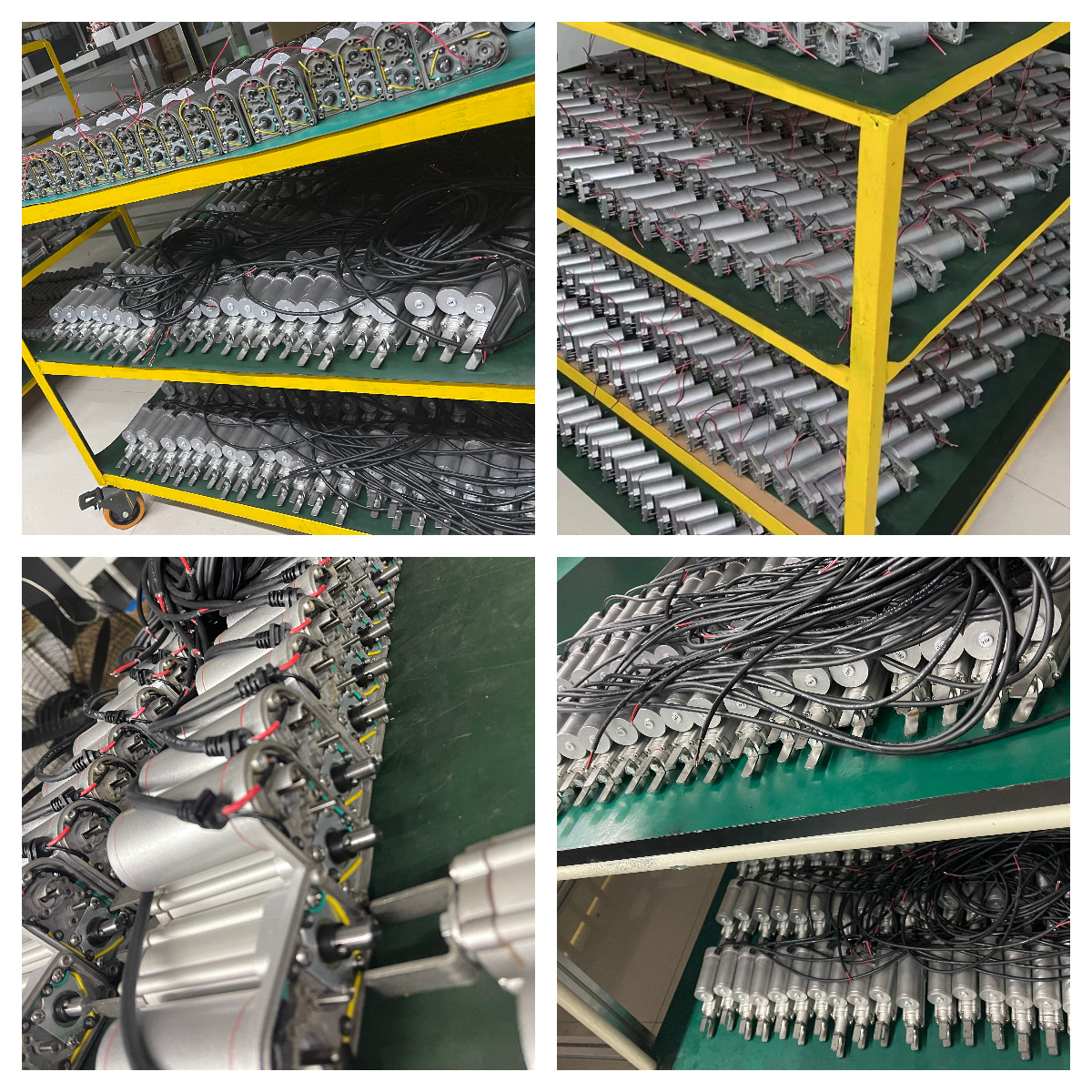

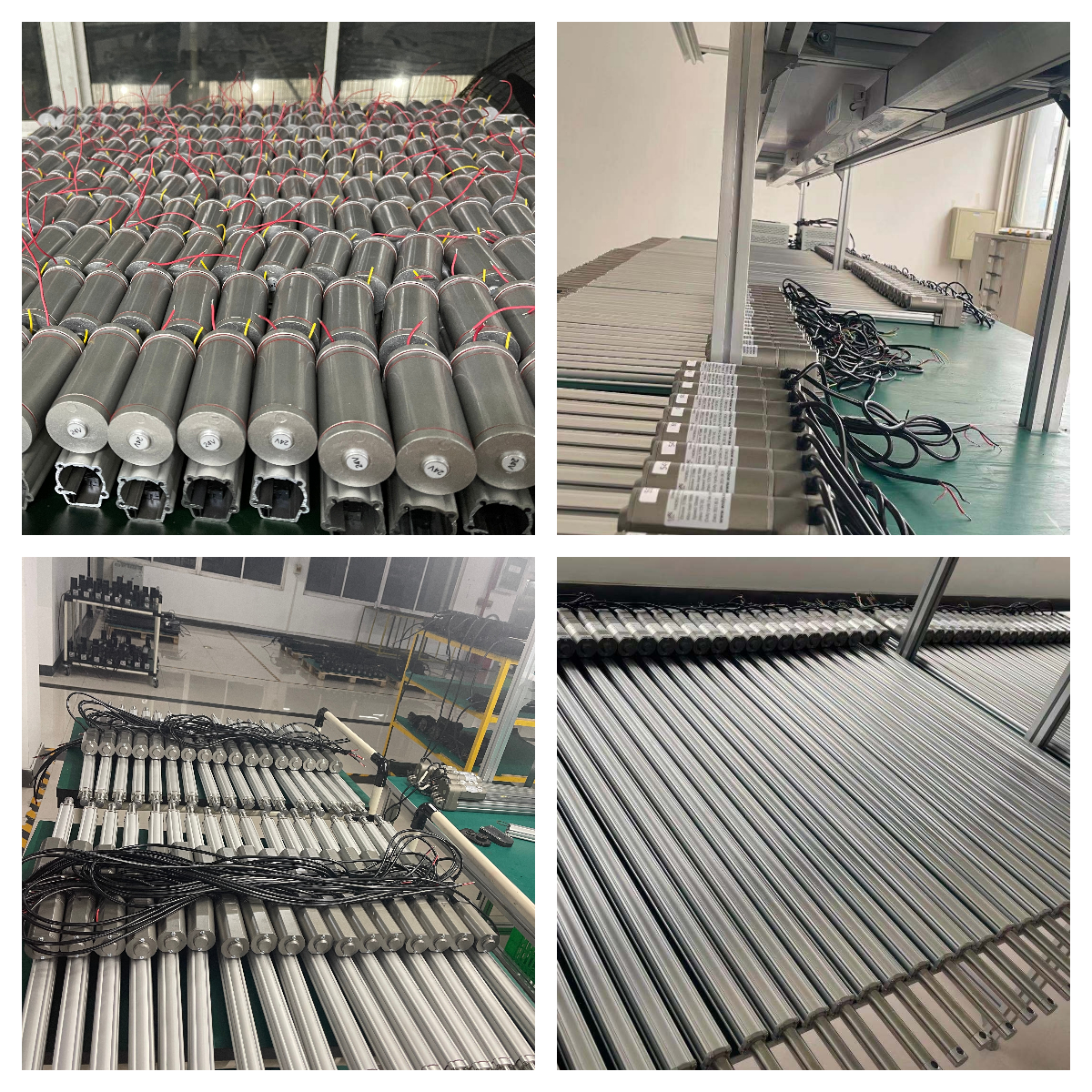

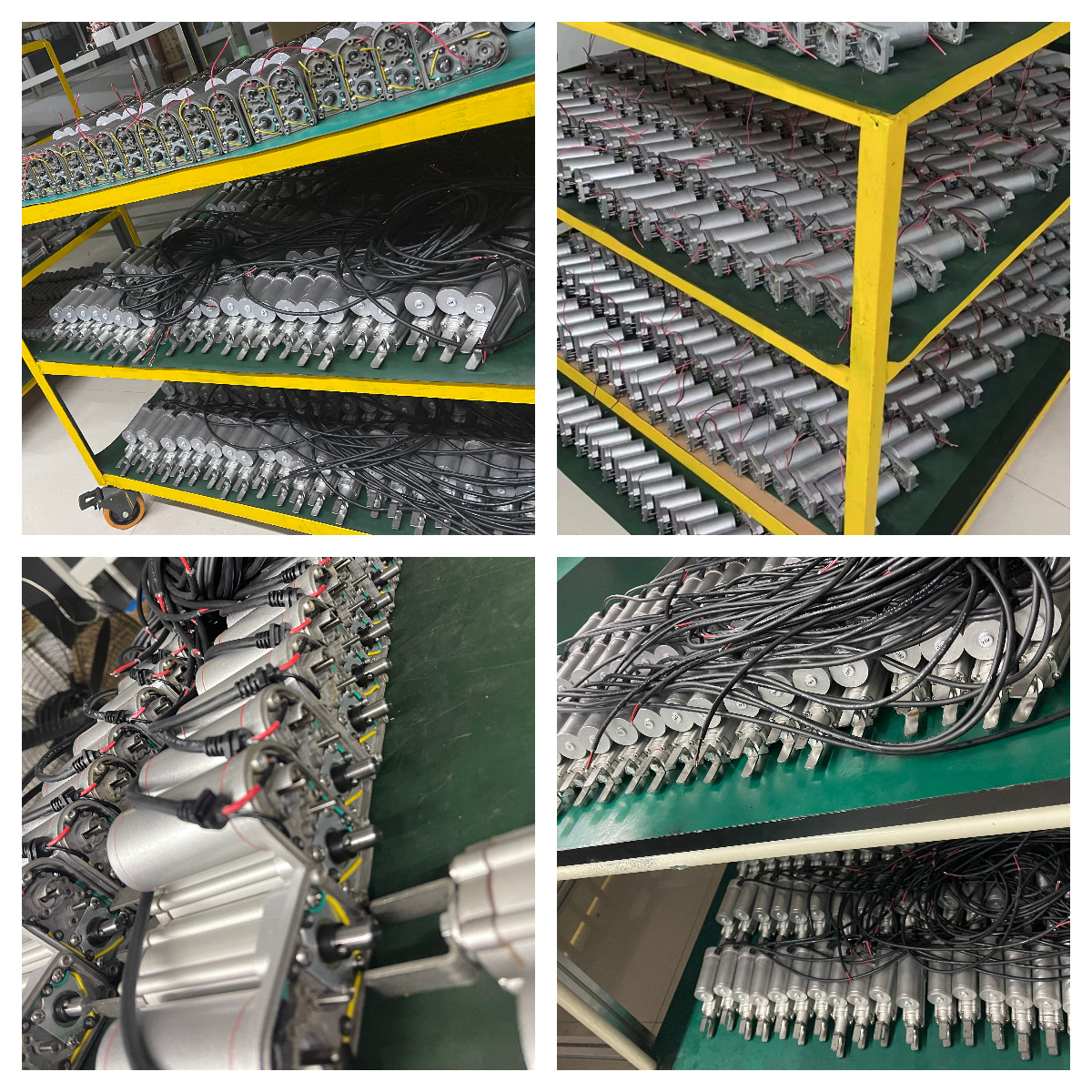

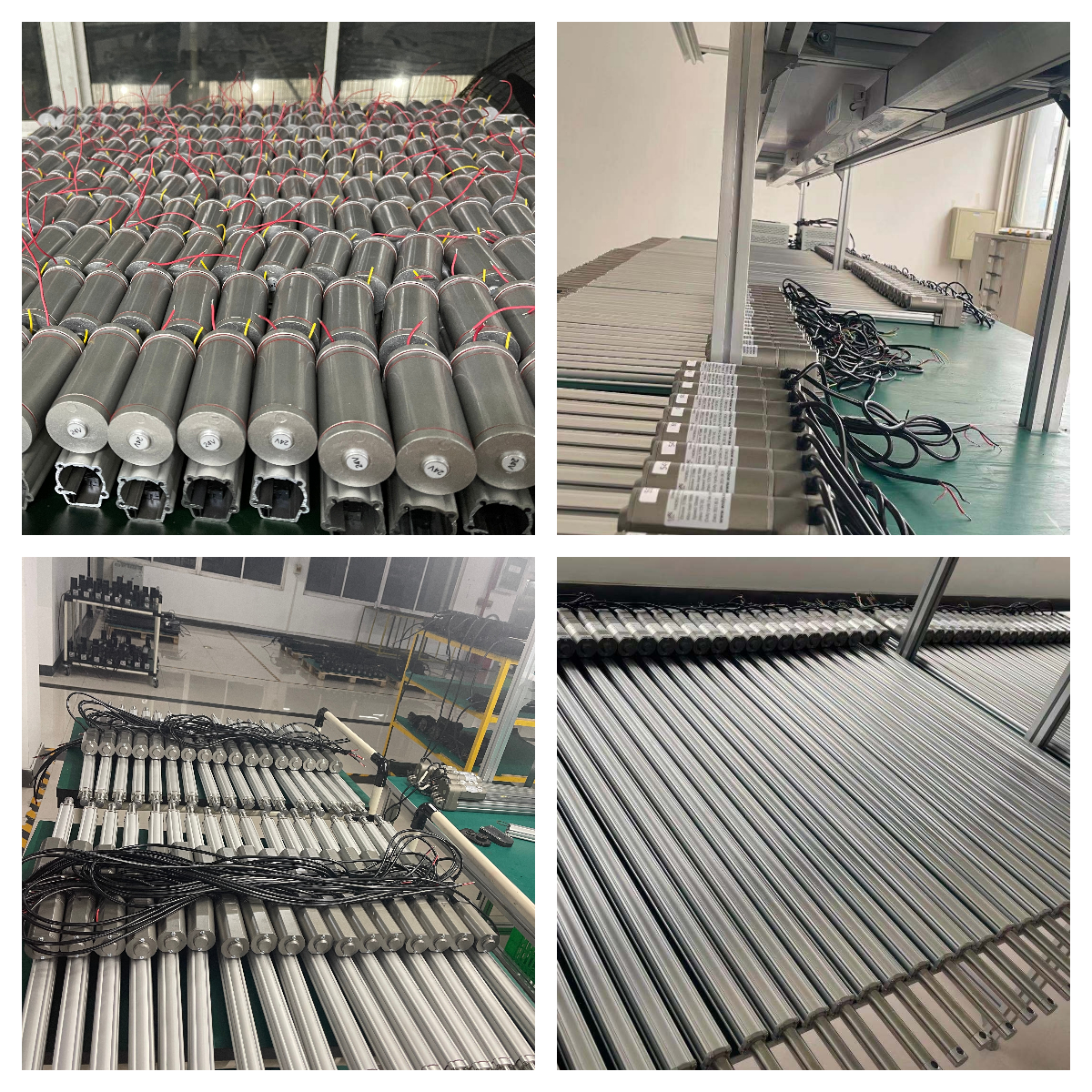

●Various Linear Actuators Are Ready In Stock

●Electric Linear Actuator Action Test Steps

Electric linear actuator is a device that realizes linear motion through motor drive,which is often used in industrial automation system.Motion test is an important step to evaluate the performance and verify the function of the device.The following are the general steps for device action testing:

1.Preparation:Confirm whether the power supply of the device is normal,check whether the connection of the control system and the power supply are stable.

2.running direction test: the running direction test is carried out first,and the device is moved forward and backward respectively.By operating the direction switch or button in the control system,observe whether the motion direction of the device meets the expectation.

3.running speed test: the running speed of the test device can usually be adjusted by the speed adjustment device or governor in the control system. Set the device to different speeds and observe whether the motion speed of the device meets the expected requirements.

4.stroke test:test the stroke range of the electric push rod,through the control system in the stroke switch or position sensor to achieve.Set the device at different travel positions and observe whether the device can be stopped within the predetermined travel range.

5.load test:load test can also be carried out in the action test,that is,add the corresponding load to the device,and observe the operation of the device under load.Load testing can evaluate the load carrying capacity and stability of the device.

6.repeated testing and recording data:repeated testing of the above test steps to ensure the stability of the device.During the test,key data such as run time,speed,stroke position,etc.are recorded for subsequent analysis and evaluation.

7.Troubleshooting:If an anomaly or fault is found during the action test,it needs to be investigated and repaired.Check the power supply,control system,transmission device and other parts of the device to ensure their normal operation.

Through the above action test,the performance of the electric push rod can be evaluated to verify whether it meets the design requirements and expected goals.At the same time,the action test can also find potential problems and faults,and take timely repair measures to ensure the normal operation of the device.

This linear actuator has 7000N(700kg)maximum load capacity and 900mm(0.9 meter)maximum stroke length.The actuator is waterproof and is powered by a 12V/24V/36V/48V DC electric motor,which ensures stable and durable performance under temperature from -40 to 65°C.Electric linear actuators are versatile devices that provide reliable and efficient linear motion solutions in a wide range of applications.

●ALM Linear Actuators Technical Parameters

●ALM Linear Actuators Details Show

●Various Linear Actuators Are Ready In Stock

●Electric Linear Actuator Action Test Steps

Electric linear actuator is a device that realizes linear motion through motor drive,which is often used in industrial automation system.Motion test is an important step to evaluate the performance and verify the function of the device.The following are the general steps for device action testing:

1.Preparation:Confirm whether the power supply of the device is normal,check whether the connection of the control system and the power supply are stable.

2.running direction test: the running direction test is carried out first,and the device is moved forward and backward respectively.By operating the direction switch or button in the control system,observe whether the motion direction of the device meets the expectation.

3.running speed test: the running speed of the test device can usually be adjusted by the speed adjustment device or governor in the control system. Set the device to different speeds and observe whether the motion speed of the device meets the expected requirements.

4.stroke test:test the stroke range of the electric push rod,through the control system in the stroke switch or position sensor to achieve.Set the device at different travel positions and observe whether the device can be stopped within the predetermined travel range.

5.load test:load test can also be carried out in the action test,that is,add the corresponding load to the device,and observe the operation of the device under load.Load testing can evaluate the load carrying capacity and stability of the device.

6.repeated testing and recording data:repeated testing of the above test steps to ensure the stability of the device.During the test,key data such as run time,speed,stroke position,etc.are recorded for subsequent analysis and evaluation.

7.Troubleshooting:If an anomaly or fault is found during the action test,it needs to be investigated and repaired.Check the power supply,control system,transmission device and other parts of the device to ensure their normal operation.

Through the above action test,the performance of the electric push rod can be evaluated to verify whether it meets the design requirements and expected goals.At the same time,the action test can also find potential problems and faults,and take timely repair measures to ensure the normal operation of the device.

Founded in year of 2005,from a small workshop KUNSHAN TIANHE BALL SCREW FACTORY,ALM group has grown fast and has four production workshops now for ball screw,lead screw,linear motor,linear actuator,linear guideways and related CNC machining.Factory area is over 15000 square meters,129 employees.Our factory is equipped with 15 automated production line.Products are 100% inspected before shipping.ALM has obtained ISO9001,IATF16949,CE,RoHS certificate. Over 25 distributors all over the world.

ALM manufactures and supplies high quality linear motion components for customers in fields of aircraft,satellite,medical, Instrumentation,Robotics,Automobile,Electrical & Electronics,Textile,Medical,Food & Beverages,General Industry and so on.With super quality and service,ALM has been widely recognized and highly valued by its high-end and picky customers,and thus remains at the top of their vendor lists.

ALM R&D Team

ALM's office

ALM's workshop

ALM product processing

ALM inspection equipment

ALM's warehouse

Linear Actuator Shipping

ALM Exhibition

Customer Visit

Founded in year of 2005,from a small workshop KUNSHAN TIANHE BALL SCREW FACTORY,ALM group has grown fast and has four production workshops now for ball screw,lead screw,linear motor,linear actuator,linear guideways and related CNC machining.Factory area is over 15000 square meters,129 employees.Our factory is equipped with 15 automated production line.Products are 100% inspected before shipping.ALM has obtained ISO9001,IATF16949,CE,RoHS certificate. Over 25 distributors all over the world.

ALM manufactures and supplies high quality linear motion components for customers in fields of aircraft,satellite,medical, Instrumentation,Robotics,Automobile,Electrical & Electronics,Textile,Medical,Food & Beverages,General Industry and so on.With super quality and service,ALM has been widely recognized and highly valued by its high-end and picky customers,and thus remains at the top of their vendor lists.

ALM R&D Team

ALM's office

ALM's workshop

ALM product processing

ALM inspection equipment

ALM's warehouse

Linear Actuator Shipping

ALM Exhibition

Customer Visit

Patent Certificate for invention and utility model

ISO Certificate

CE Certificate

Excellent HighTech Enterprise

Leading Talents Certificate

Patent Certificate for invention and utility model

ISO Certificate

CE Certificate

Excellent HighTech Enterprise

Leading Talents Certificate