- Home

- Products

- Video

- Blog

- Projects

- Quality Control

- About ALM

- News

- Support

- Contact Us

| Availability: | |

|---|---|

| Quantity: | |

0502

ALM

8483900090

Ground Miniature 0502 High Precision Ball Screw with Flange Nut.Unlike lead screws,which have gaps between nuts and screws,ball screws can and often are preload to eliminate the gaps.This is usually done by using a ball whose diameter is slightly larger than the space between the screw and nut raceway.Some lead screws offer nut designs that eliminate clearance,but these often increase friction and reduce efficiency.

| Material | Gcr15 or 9cr18 |

| Accuracy grade | C3,C5 |

| MOQ | 1 piece available for test |

| Delivery time | Samples 10~15 days, small order 20 days,bulk order 20~30 days. |

| Packing | Plastic bag + wooden box or according to customers' demands |

| Other models | 0401, 0501, 0502, 0601, 0602, 0801, 0802, 0803, 0804, 0805 1001, 1002, 1003, 1004, 1201, 1202, 1203, 1204, 1205, 1210, 1402, 1403, 1404, 1405, 1602, 1603, 1604, 1605, 1608, 1610, 2002, 2003, 2004, 2005, 2006, 2010, 2020, 2502, 2503, 2504, 2505, 2510, 2512, 2525, 3205, 3206, 3208, 3210, 3212, 3216, 4005, 4008, 4010, 4012, 4016, 5005, 5010, 5012, 5016, 5020, 6310, 6312, 6316, 6320, 8010, 8016, 8020, etc |

| Mating parts | Nut housing,ball screw support BK,BF,EK,EF,FK,FF,end maching service is available |

Notes:Above is part of standard models,other model or nut type is available upon drawing.For more information,pls contact the salesman.

| AGF Series Ball Screw Specification |

| Our Advantages |

| Free service | Performance testing |

| Technical solution | |

| Please contact the salesman for details | |

| Custom service | Gcr15,9cr18 and other customized materials |

| Surface treatment | |

| Custom ballnut and shaft end machining | |

| Maintenance and assembly | |

| Please contact the salesman for details | |

| Ball Screw Application |

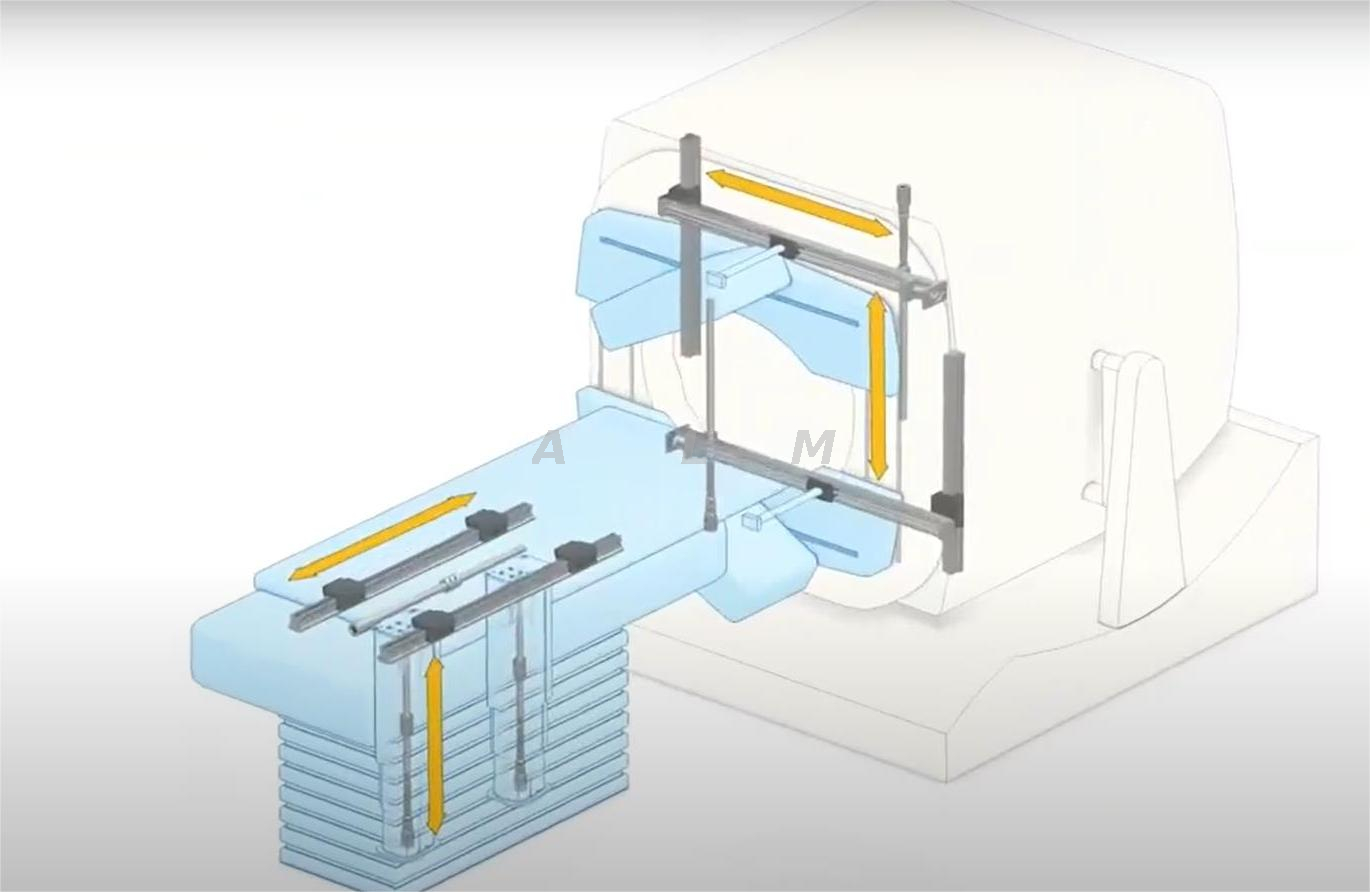

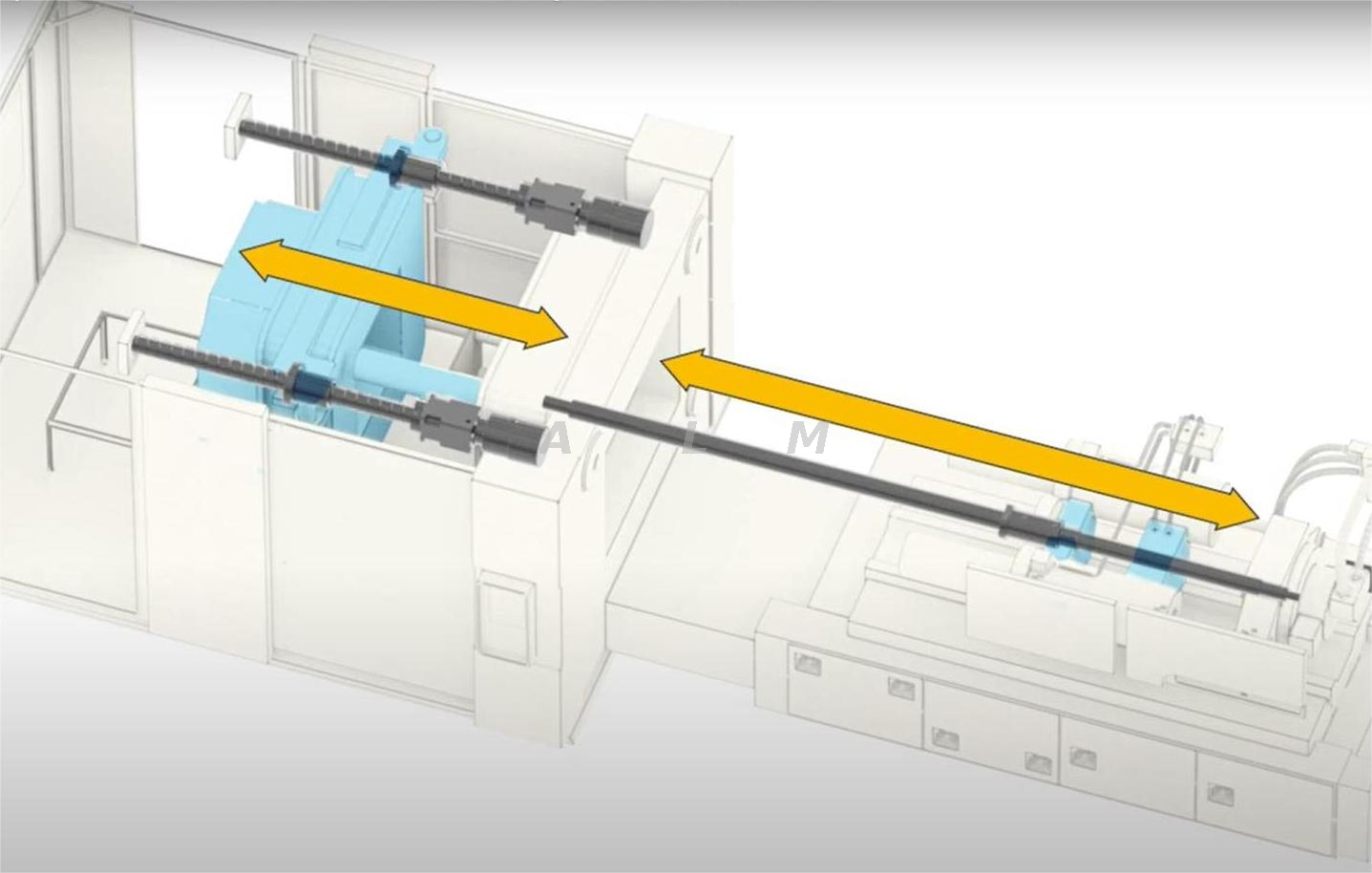

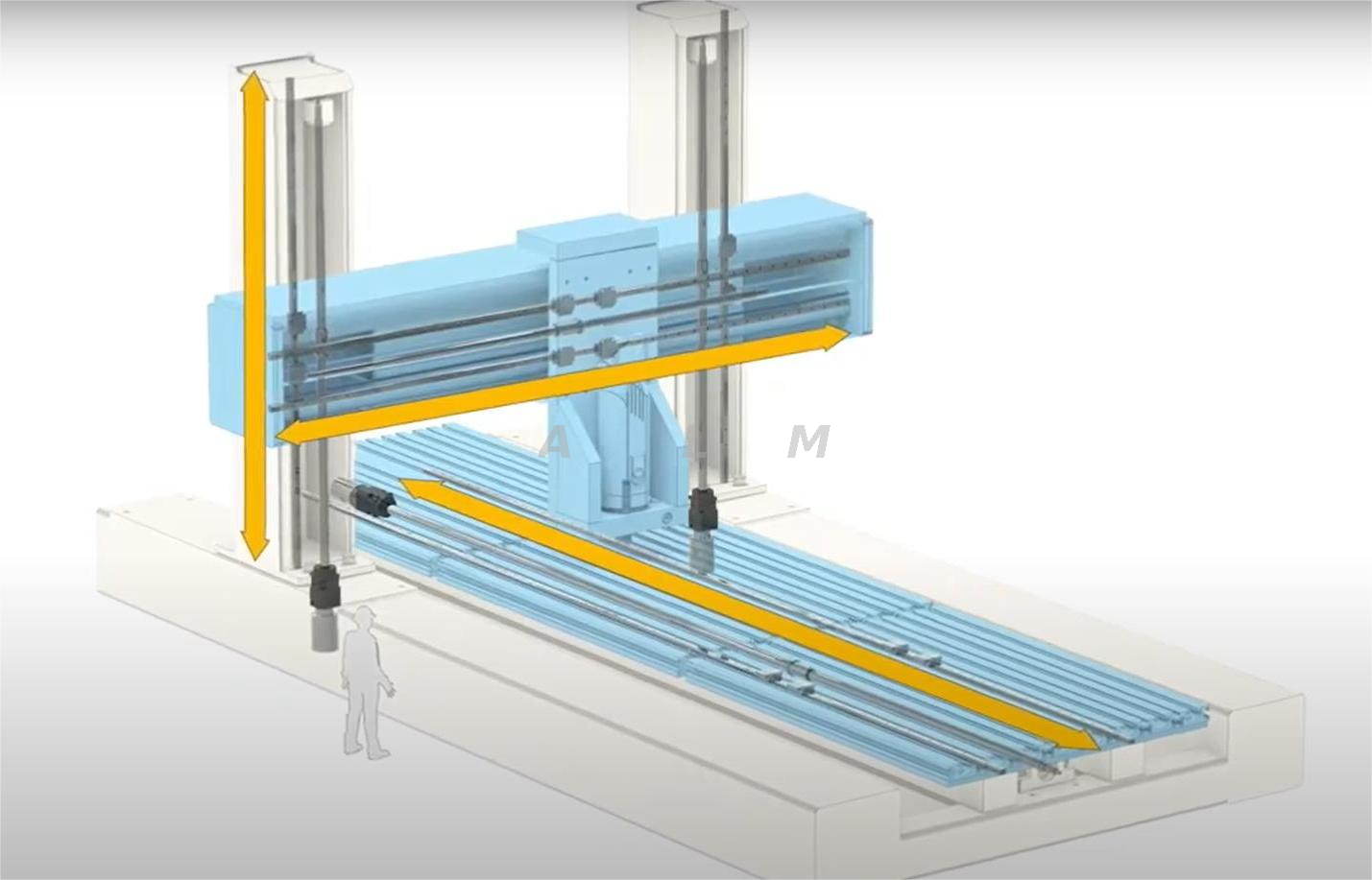

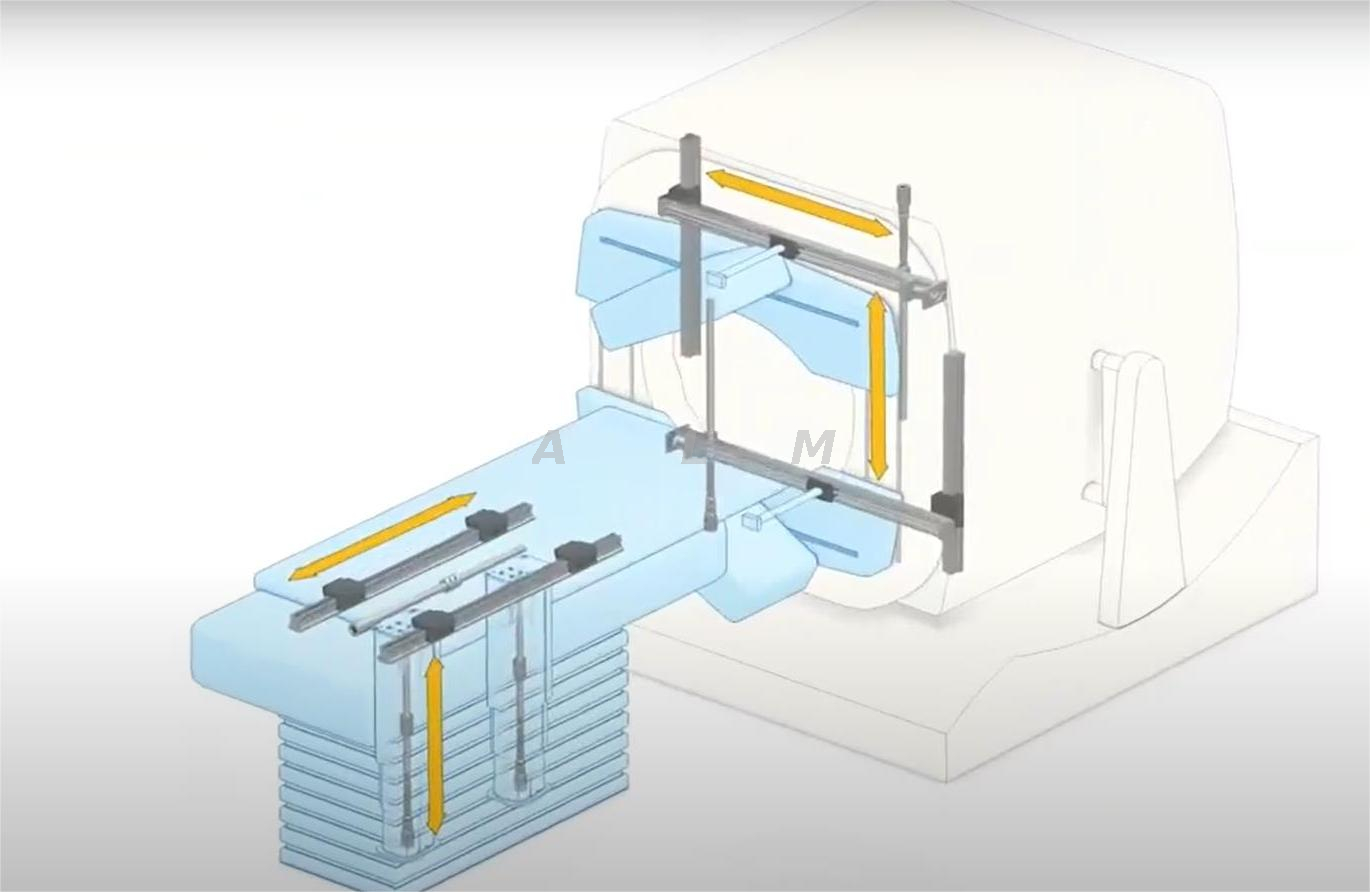

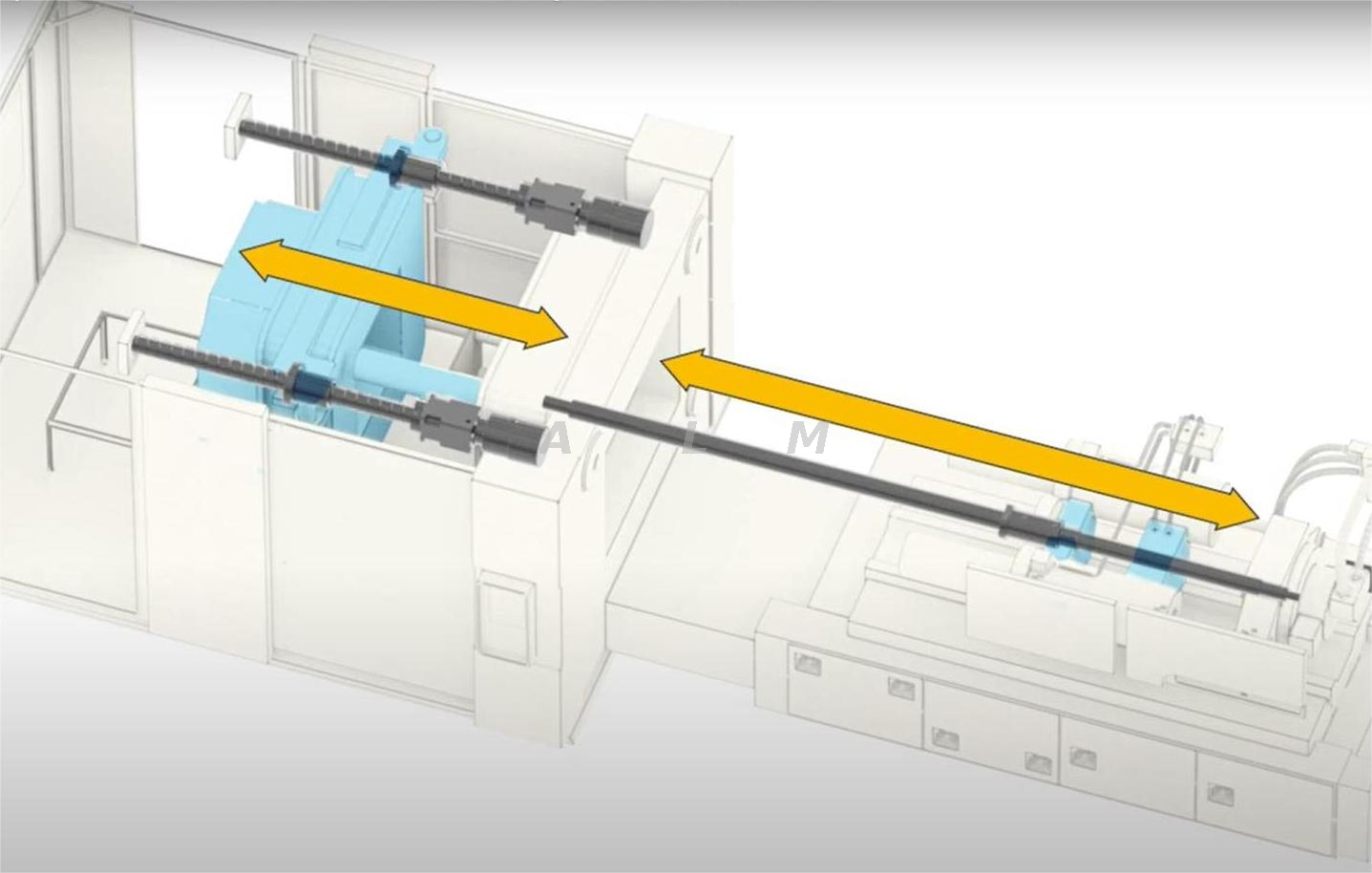

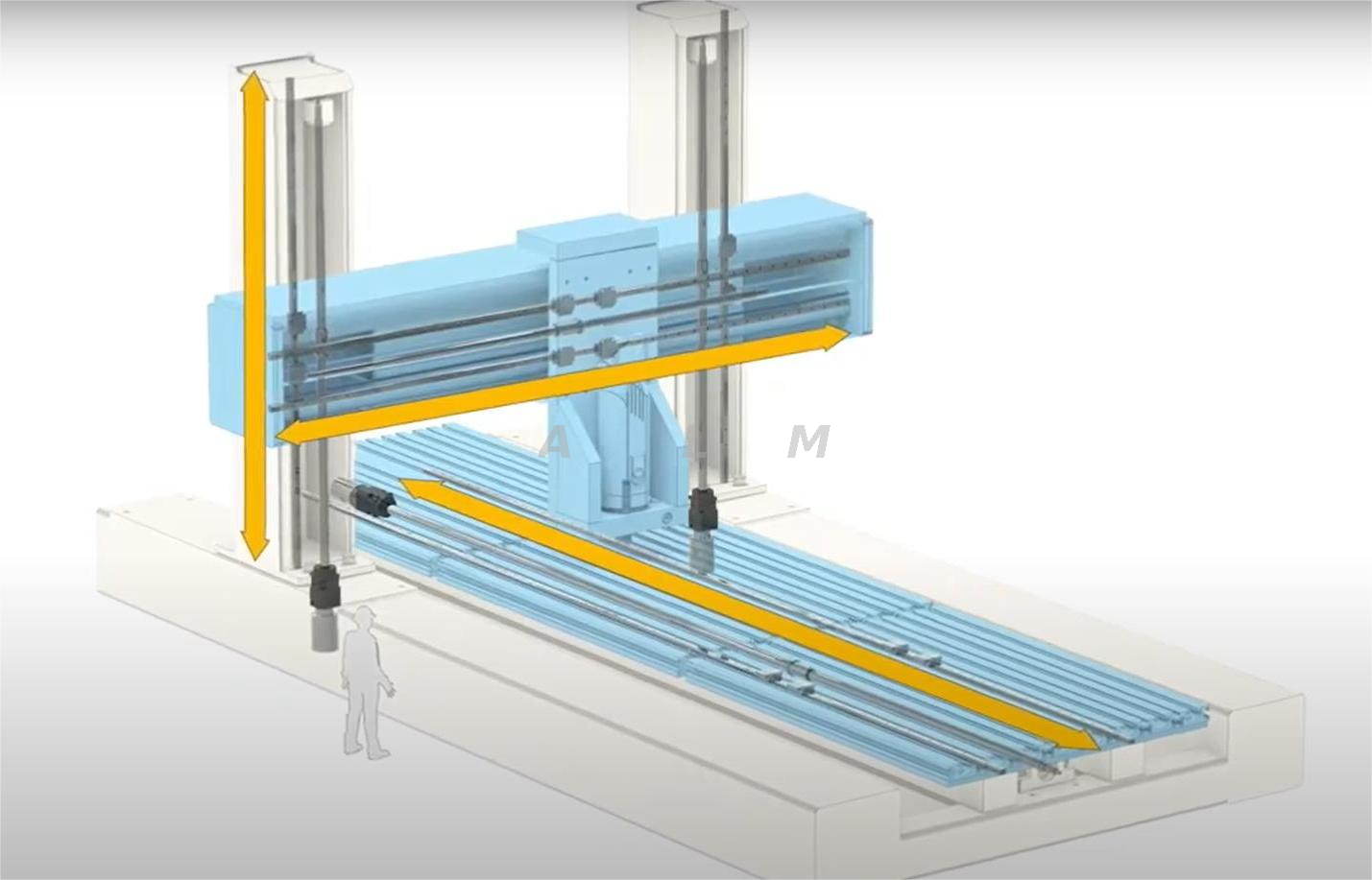

Ball screws are more suitable for applications requiring smooth motion,efficiency,precision,precision and long continuous or high speed motion.The following figure shows the common application of ball screw.

Medical device

Solar pannel

Packging and injection mold

Woodworking machine

Machine centre

| Common Ball Screw Terms Explained |

1.Lead and Pitch

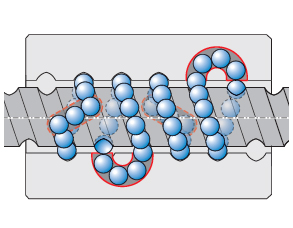

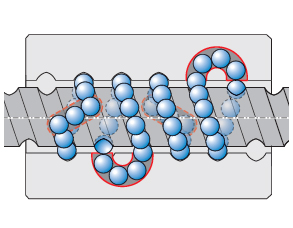

Lead and spacing are a good example of related but different specifications.The Lead refers to the linear distance traveled for each complete turn of the screw,while the pitch is the distance between the screw threads.These terms are often used interchangeably,and for single-start screws(as defined below),lead and pitch are equivalent.However,for screws with multiple starts,the lead and pitch are not equal.

2.Circuits and Turns

Also related is the concept of ball circuits and turns.A ball circuit is a closed path of recirculating balls."Turns"refers to the number of trips the ball can make around the screw shaft before recirculating.The relationship between the Circuits and the turns is affected by the recirculation method.The return cue uses either a deflector or a threaded to threaded(also known as a cross)method to recirculate each turn of the ball individually.So the number of turns is equal to the number of circuits.

Internal Deflector Recirculation

Recirculating balls can pass through multiple threads as the ball returns through an internal channel or an external tube,so a Circuit can have multiple ball turns.In other words,the ball bearings go several times around the screw shaft before recirculating.Multi-start ball screw assemblies usually use the inner channel recirculation method.The nut body can be designed to have multiple Circuits by incorporating multiple internal recirculation channels into it.

Internal End Cap Recirculation

External Tube Recirculation

3.Starts(and Lead revisited)

Return to the lead for a minute.This is not only an important specification for linear travel and speed,but also because the lead of the ball screw determines how many balls are in the load zone(in contact with the screw shaft and ball nut)and therefore has a direct impact on the load capacity.

Given the geometry of the screw assembly,it makes sense that as the screw lead gets larger,the number of rails inside the ball nut gets smaller,and so there are fewer balls to carry the load. Although larger lead screws provide longer travel per turn and higher speeds,their ability to deliver high load capacity is compromised.In theory,it is possible to increase the number of ball tracks by extending the ball nuts,but manufacturing constraints and limitations on the length of the ball nuts make this an impractical solution.

To solve the problem of fewer turns in long lead assemblies,ball screws and nuts can be manufactured with multiple "starter" or ball tracks.This puts more ball bearings into the load bearing area and increases the load capacity.

Single and Double start screw

Multiple ball screw has safety advantages over single starting screw.If one ball track is damaged or tired,balls in other tracks can help prevent catastrophic failure.Furthermore,when a single-starting ball nut is used with a multi-starting screw shaft,the assembly can be refurbished by replacing only the ball nut and not the screw shaft.The new ball nuts are mounted on existing screws in unused rails,saving cost and avoiding the need to completely remove the screw system.

While this may seem like a semantic exercise,understanding these terms and the differences between them can help designers and engineers avoid incorrect assumptions about ball screw operation and performance.

Ground Miniature 0502 High Precision Ball Screw with Flange Nut.Unlike lead screws,which have gaps between nuts and screws,ball screws can and often are preload to eliminate the gaps.This is usually done by using a ball whose diameter is slightly larger than the space between the screw and nut raceway.Some lead screws offer nut designs that eliminate clearance,but these often increase friction and reduce efficiency.

| Material | Gcr15 or 9cr18 |

| Accuracy grade | C3,C5 |

| MOQ | 1 piece available for test |

| Delivery time | Samples 10~15 days, small order 20 days,bulk order 20~30 days. |

| Packing | Plastic bag + wooden box or according to customers' demands |

| Other models | 0401, 0501, 0502, 0601, 0602, 0801, 0802, 0803, 0804, 0805 1001, 1002, 1003, 1004, 1201, 1202, 1203, 1204, 1205, 1210, 1402, 1403, 1404, 1405, 1602, 1603, 1604, 1605, 1608, 1610, 2002, 2003, 2004, 2005, 2006, 2010, 2020, 2502, 2503, 2504, 2505, 2510, 2512, 2525, 3205, 3206, 3208, 3210, 3212, 3216, 4005, 4008, 4010, 4012, 4016, 5005, 5010, 5012, 5016, 5020, 6310, 6312, 6316, 6320, 8010, 8016, 8020, etc |

| Mating parts | Nut housing,ball screw support BK,BF,EK,EF,FK,FF,end maching service is available |

Notes:Above is part of standard models,other model or nut type is available upon drawing.For more information,pls contact the salesman.

| AGF Series Ball Screw Specification |

| Our Advantages |

| Free service | Performance testing |

| Technical solution | |

| Please contact the salesman for details | |

| Custom service | Gcr15,9cr18 and other customized materials |

| Surface treatment | |

| Custom ballnut and shaft end machining | |

| Maintenance and assembly | |

| Please contact the salesman for details | |

| Ball Screw Application |

Ball screws are more suitable for applications requiring smooth motion,efficiency,precision,precision and long continuous or high speed motion.The following figure shows the common application of ball screw.

Medical device

Solar pannel

Packging and injection mold

Woodworking machine

Machine centre

| Common Ball Screw Terms Explained |

1.Lead and Pitch

Lead and spacing are a good example of related but different specifications.The Lead refers to the linear distance traveled for each complete turn of the screw,while the pitch is the distance between the screw threads.These terms are often used interchangeably,and for single-start screws(as defined below),lead and pitch are equivalent.However,for screws with multiple starts,the lead and pitch are not equal.

2.Circuits and Turns

Also related is the concept of ball circuits and turns.A ball circuit is a closed path of recirculating balls."Turns"refers to the number of trips the ball can make around the screw shaft before recirculating.The relationship between the Circuits and the turns is affected by the recirculation method.The return cue uses either a deflector or a threaded to threaded(also known as a cross)method to recirculate each turn of the ball individually.So the number of turns is equal to the number of circuits.

Internal Deflector Recirculation

Recirculating balls can pass through multiple threads as the ball returns through an internal channel or an external tube,so a Circuit can have multiple ball turns.In other words,the ball bearings go several times around the screw shaft before recirculating.Multi-start ball screw assemblies usually use the inner channel recirculation method.The nut body can be designed to have multiple Circuits by incorporating multiple internal recirculation channels into it.

Internal End Cap Recirculation

External Tube Recirculation

3.Starts(and Lead revisited)

Return to the lead for a minute.This is not only an important specification for linear travel and speed,but also because the lead of the ball screw determines how many balls are in the load zone(in contact with the screw shaft and ball nut)and therefore has a direct impact on the load capacity.

Given the geometry of the screw assembly,it makes sense that as the screw lead gets larger,the number of rails inside the ball nut gets smaller,and so there are fewer balls to carry the load. Although larger lead screws provide longer travel per turn and higher speeds,their ability to deliver high load capacity is compromised.In theory,it is possible to increase the number of ball tracks by extending the ball nuts,but manufacturing constraints and limitations on the length of the ball nuts make this an impractical solution.

To solve the problem of fewer turns in long lead assemblies,ball screws and nuts can be manufactured with multiple "starter" or ball tracks.This puts more ball bearings into the load bearing area and increases the load capacity.

Single and Double start screw

Multiple ball screw has safety advantages over single starting screw.If one ball track is damaged or tired,balls in other tracks can help prevent catastrophic failure.Furthermore,when a single-starting ball nut is used with a multi-starting screw shaft,the assembly can be refurbished by replacing only the ball nut and not the screw shaft.The new ball nuts are mounted on existing screws in unused rails,saving cost and avoiding the need to completely remove the screw system.

While this may seem like a semantic exercise,understanding these terms and the differences between them can help designers and engineers avoid incorrect assumptions about ball screw operation and performance.

ALM originally established in year of 2005.From a small factory,ALM nowadays has four production workshops for ball screw,lead screw,linear motor,linear actuator,linear guideways and related CNC machining parts for automation industry.Total areas over 7000 square meters,109 employees.Above 8 technical engineers are with over 20 years’ experience in linear motion filed.

ALM manufactures and supplies high quality linear motion components for customers in fields of aircraft, satellite,medical,Instrumentation,Robotics,Automobile,Electrical & Electronics,Textile,Medical,Food & Beverages,General Industry and so on.Customers cover more than 65 countries in Europe,North America,South Asia,Middle East,Africa,Latin America etc.With super quality and service,ALM has been widely recognized and highly valued by its high-end and picky customers, and thus remains at the top of their vendor lists.

ALM key production machines are imported,like high precision CNC grinding machine,3 axis,4 axis machining centre,internal and external grinding centre,CNC lathe.In addition,with advanced production management,ALM obtained the quality certificate ISO9001:2008 and IATF16949.And through our R&D department dedication over 16 years,we possess more than 26 national patents.

ALM's office

ALM's workshop

ALM product processing

ALM's warehouse

Customer Visit

ALM originally established in year of 2005.From a small factory,ALM nowadays has four production workshops for ball screw,lead screw,linear motor,linear actuator,linear guideways and related CNC machining parts for automation industry.Total areas over 7000 square meters,109 employees.Above 8 technical engineers are with over 20 years’ experience in linear motion filed.

ALM manufactures and supplies high quality linear motion components for customers in fields of aircraft, satellite,medical,Instrumentation,Robotics,Automobile,Electrical & Electronics,Textile,Medical,Food & Beverages,General Industry and so on.Customers cover more than 65 countries in Europe,North America,South Asia,Middle East,Africa,Latin America etc.With super quality and service,ALM has been widely recognized and highly valued by its high-end and picky customers, and thus remains at the top of their vendor lists.

ALM key production machines are imported,like high precision CNC grinding machine,3 axis,4 axis machining centre,internal and external grinding centre,CNC lathe.In addition,with advanced production management,ALM obtained the quality certificate ISO9001:2008 and IATF16949.And through our R&D department dedication over 16 years,we possess more than 26 national patents.

ALM's office

ALM's workshop

ALM product processing

ALM's warehouse

Customer Visit

Patent Certificate for invention and utility model

Patent Certificate for invention and utility model

1.Why can ALM be your better option for linear motion components?

With more than 16 years of industry experience,quality assurance,factory directly price.

2.What is your main products ?

Our Main products are consist of ball screw,linear guide,lead screw,linear module and linear motor.

3.When can I get the quotation?

We usually quote within 24 hours after we get your inquiry.If you are very urgent to get the price,please call us or tell us in your email so that we will regard your inquiry priority.

4.How to Custom-made?

1.Why can ALM be your better option for linear motion components?

With more than 16 years of industry experience,quality assurance,factory directly price.

2.What is your main products ?

Our Main products are consist of ball screw,linear guide,lead screw,linear module and linear motor.

3.When can I get the quotation?

We usually quote within 24 hours after we get your inquiry.If you are very urgent to get the price,please call us or tell us in your email so that we will regard your inquiry priority.

4.How to Custom-made?