- Home

- Products

- Video

- Blog

- Projects

- Quality Control

- About ALM

- News

- Support

- Contact Us

| Availability: | |

|---|---|

| Quantity: | |

8x1

ALM

8483900090

The miniature ball screw diameter is 8mm,the lead and pitch of the ball screw is 1mm.8x1 ball screw with square ballnut,no need ballnut seat.Ball screw can be mounted on the workbench directly to save system space.0801 ball screw has features of cost-effective,high efficiency.

| Product name | Long Service Life Square Ballnut 8x1 Miniature Ball Screw for 3D Printer |

| Material | Gcr15 or 9cr18 |

| Accuracy grade | C3,C5,C7 |

| MOQ | 1 piece available for test |

| Delivery time | Samples 10~15 days, small order 20 days,bulk order 20~30 days. |

| Packing | Plastic bag + wooden box or according to customers' demands |

| Other models | 0401, 0501, 0502, 0601, 0602, 0801, 0802, 0803, 0804, 0805 1001, 1002, 1003, 1004, 1201, 1202, 1203, 1204, 1205, 1210, 1402, 1403, 1404, 1405, 1602, 1603, 1604, 1605, 1608, 1610, 2002, 2003, 2004, 2005, 2006, 2010, 2020, 2502, 2503, 2504, 2505, 2510, 2512, 2525, 3205, 3206, 3208, 3210, 3212, 3216, 4005, 4008, 4010, 4012, 4016, 5005, 5010, 5012, 5016, 5020, 6310, 6312, 6316, 6320, 8010, 8016, 8020, etc |

| Mating parts | Nut housing,ball screw support BK,BF,EK,EF,FK,FF,end maching service is available |

Notes:Above is part of standard models,other model or nut type is available upon drawing.For more information,pls contact the salesman.

| Our Advantages |

| Free service | Performance testing |

| Selection of auxiliary | |

| Technical solution | |

| Please contact the salesman for details | |

| Custom service | Stainless steel and other customized materials |

| Surface treatment | |

| Custom ballnut and shaft end machining | |

| Assembly | |

| Please contact the salesman for details | |

| Ball Screw Application |

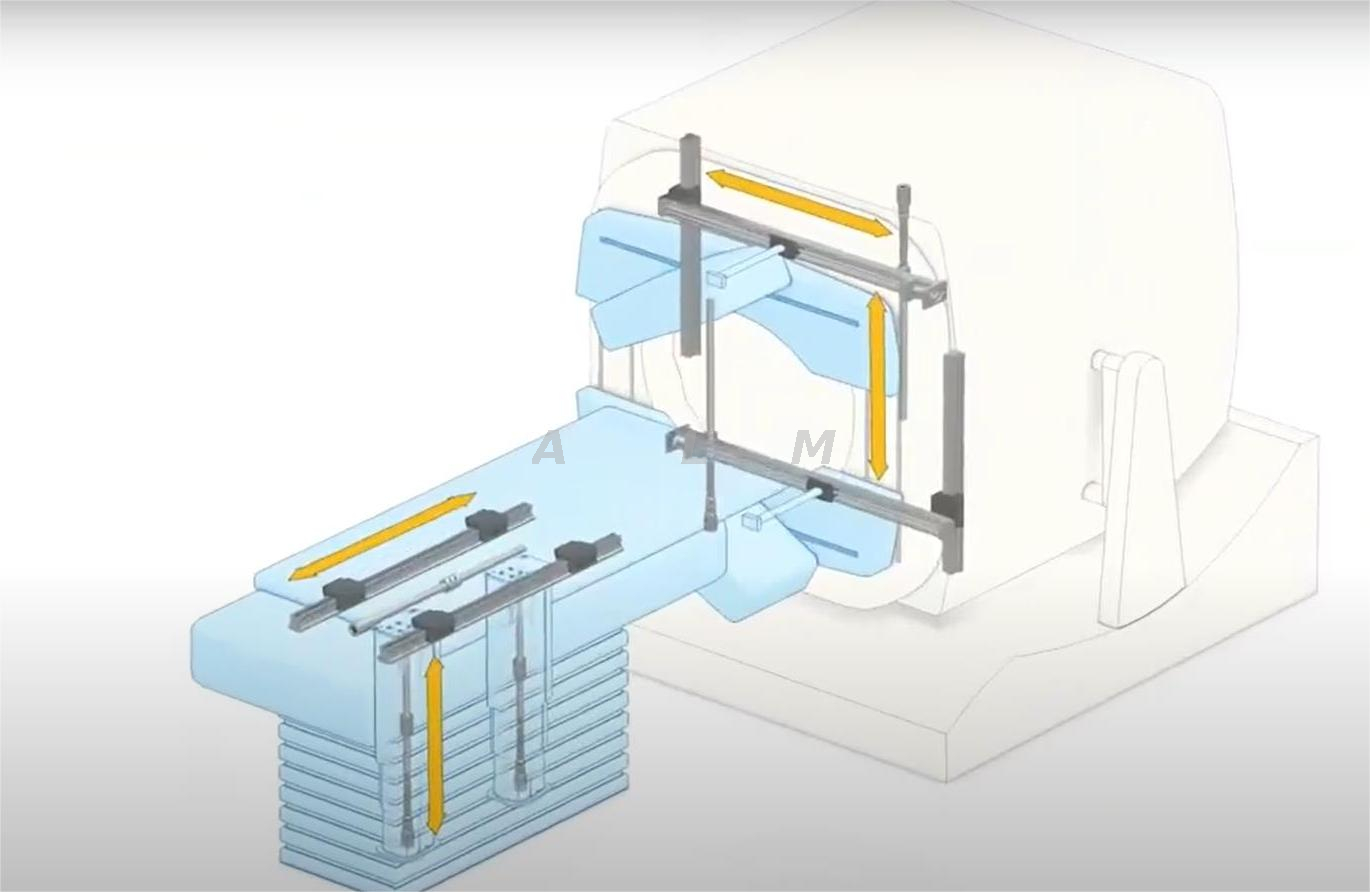

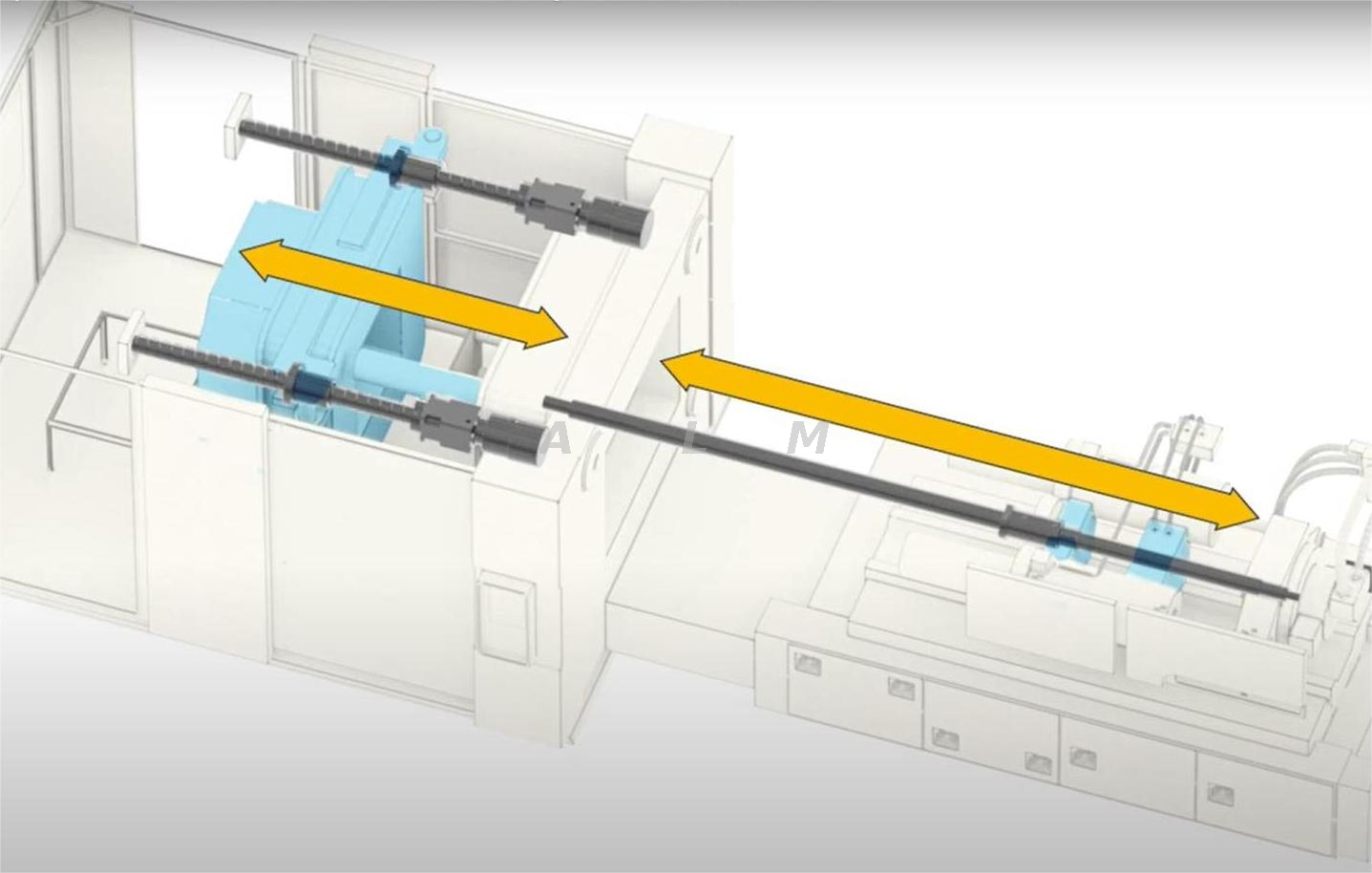

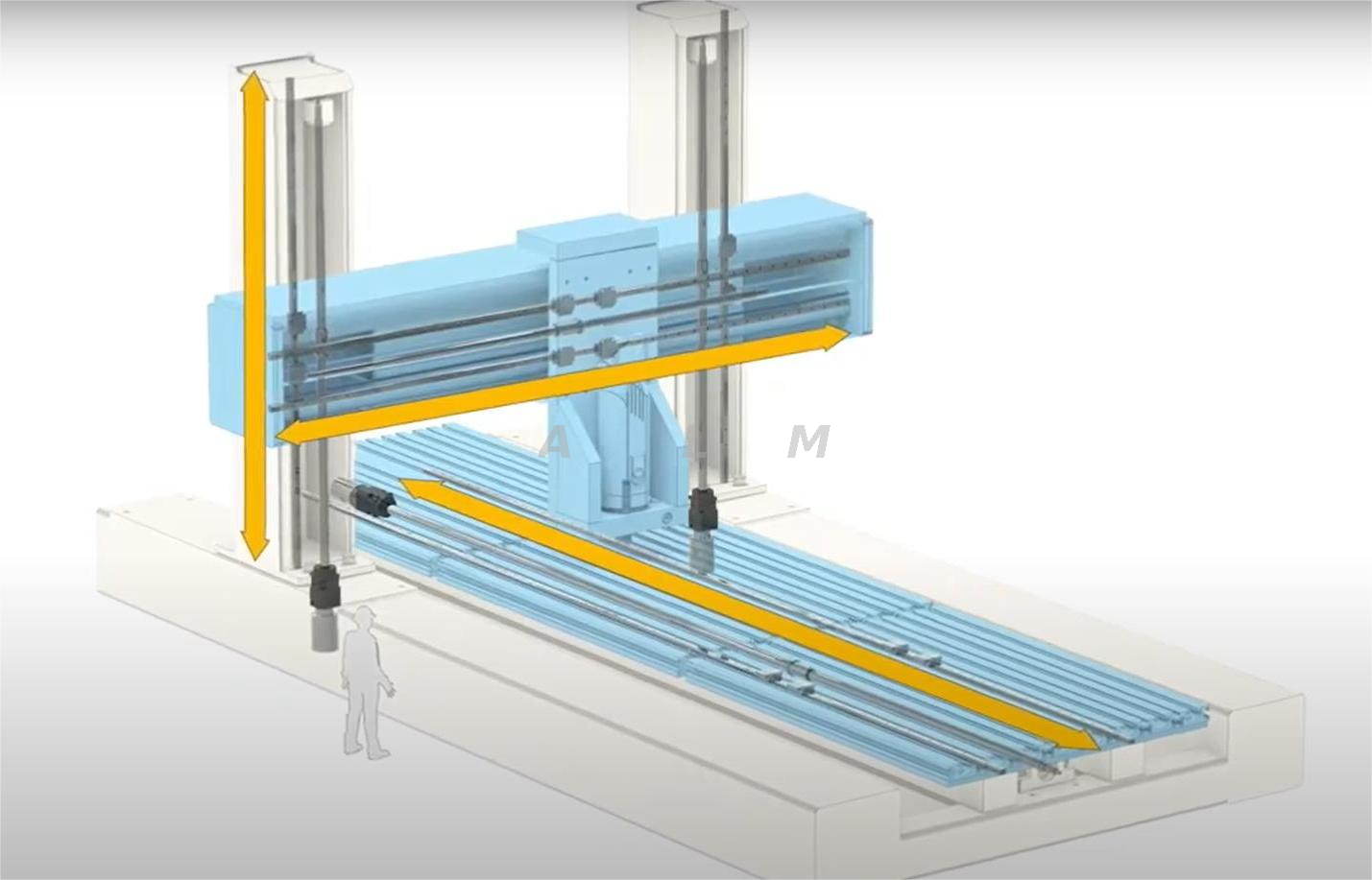

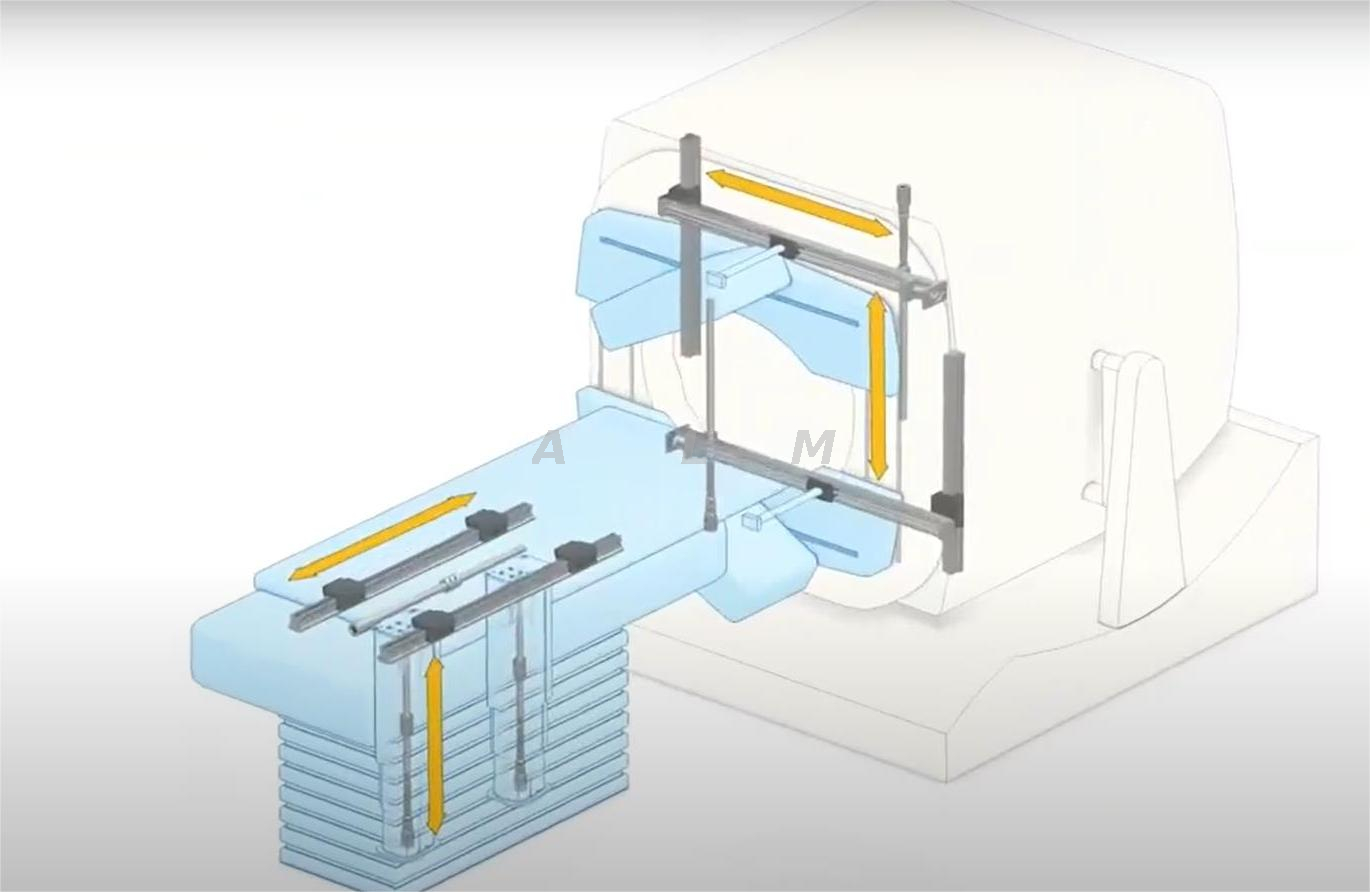

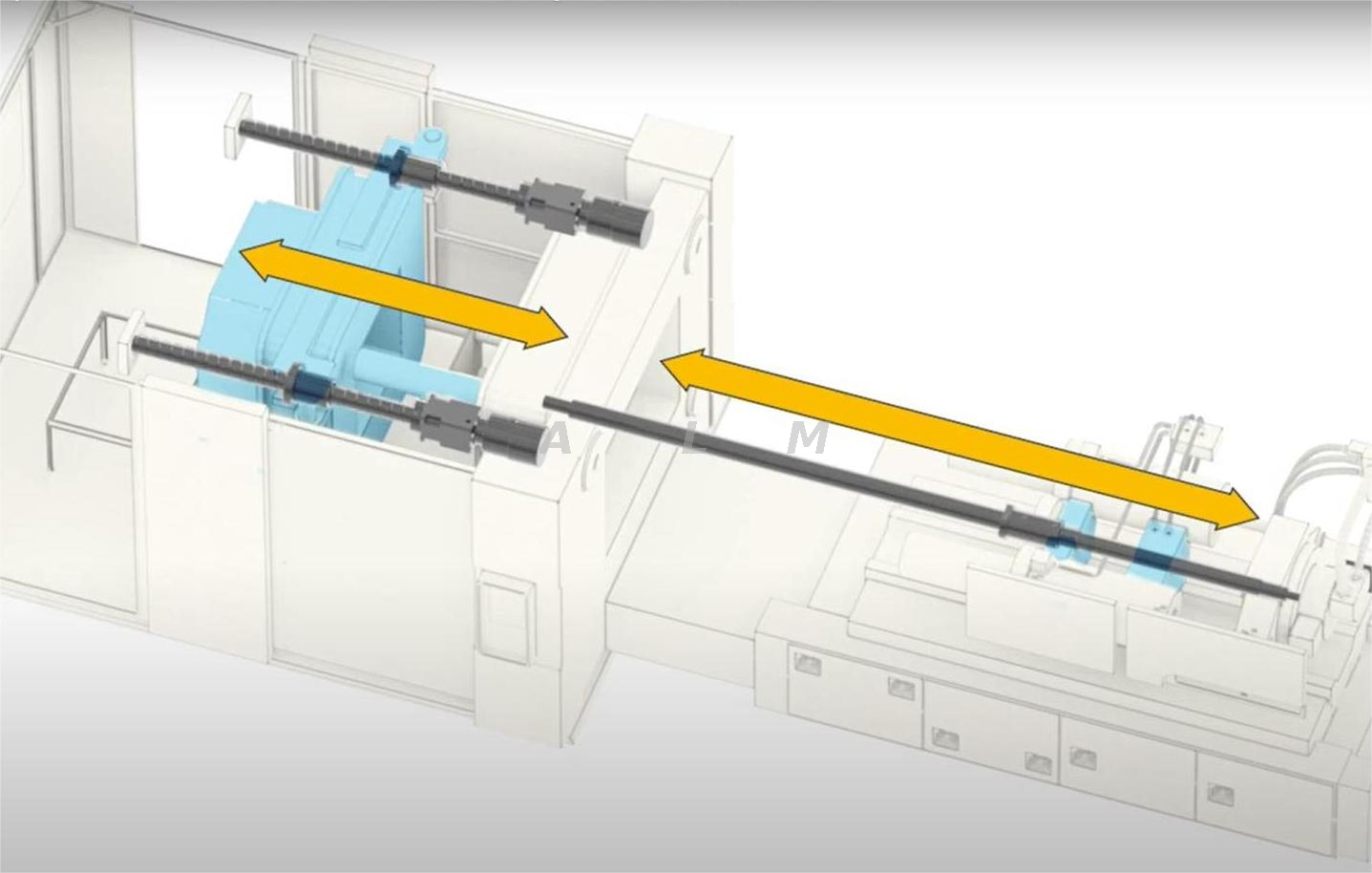

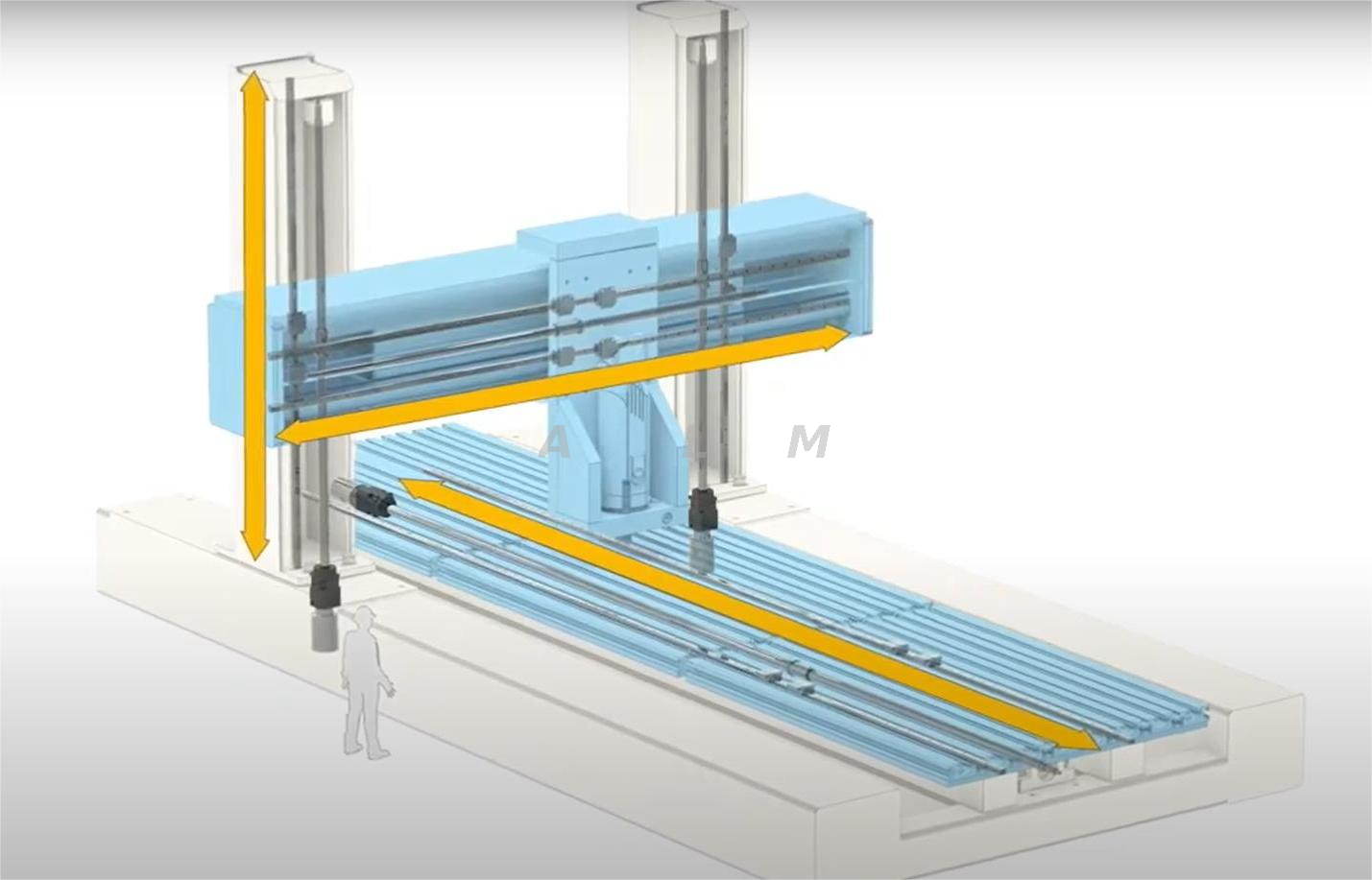

Ball screws are more suitable for applications requiring smooth motion,efficiency,precision,precision and long continuous or high speed motion.The following figure shows the common application of ball screw.

Medical device

Solar pannel

Packging and injection mold

Woodworking machine

Machine centre

| Steel Ball Circulation Mode |

Floating

Floating

Cover plate type

The end cover type

Intubation type

Cutting type

1.Floating

Floating reversing device is the most basic and widely used,with the help of reversing device on the role of the bead groove,forcing the ball rolling along the raceway,over the screw thread raceway after the tooth tip,back to the initial raceway,formed a circular ball chain,suitable for all kinds of diameter and nut style.In all circulation systems,the nut diameter of the floating reversing device can be minimized,suitable for all kinds of precision micro equipment.

2.Cover plate type

Nut with cover plate,suitable for large lead ball screw,large load,high cost performance.

3.The end cover type

Refers to the way in which the steel ball rolls along the groove between the screw shaft and the nut,passes through the through hole on the nut through the path installed on the end cover backer at both ends of the nut,and returns to the original position.It has stronger scraping effect,and the strengthening of the circulating backflow structure increases the function of high rigidity and high speed.It is suitable for the design of high speed light load and low noise.

4.Intubation type

The intubation is an evolution from the floating deflector.To guide the balls into and out of the elbow tube by means of a tongue bevel at the end of the elbow tube inserted into the hole or other form of bead stopper.

5.Cutting type

Cutting type at the same time grasp the small space with two large load characteristics,processing difficulty is higher,is suitable for some special requirements.

| Cautions About Use of Ball Screw |

Ball screw assemblies are delicate components.Therefore,extra care must be taken to prevent the ball track from damages that caused by edged component or tools.Meanwhile,the steel ball is very easily fall out of the nut or over stroke.Don't disassemble it.Cautions About Use of Ball Screws:

To prevent steel ball fall out of the nut through the disassembly of screw and nut or over stroke,please be careful while operating.If the steel ball falls out,please contact with ALM Linear Motion for further instruction.Do not attempt to reassemble,which might cause permanent damage to the ball screw.If disassemble is required,please use a transfer pipe which has minor diameter than the screwdiameter to transfer the nut to prevent falling out of the steel balls.

| ALM Micro Ball Screw Catalog Download |

Other micro ball screw models are available,kindly pls refer to the catalog below.

The miniature ball screw diameter is 8mm,the lead and pitch of the ball screw is 1mm.8x1 ball screw with square ballnut,no need ballnut seat.Ball screw can be mounted on the workbench directly to save system space.0801 ball screw has features of cost-effective,high efficiency.

| Product name | Long Service Life Square Ballnut 8x1 Miniature Ball Screw for 3D Printer |

| Material | Gcr15 or 9cr18 |

| Accuracy grade | C3,C5,C7 |

| MOQ | 1 piece available for test |

| Delivery time | Samples 10~15 days, small order 20 days,bulk order 20~30 days. |

| Packing | Plastic bag + wooden box or according to customers' demands |

| Other models | 0401, 0501, 0502, 0601, 0602, 0801, 0802, 0803, 0804, 0805 1001, 1002, 1003, 1004, 1201, 1202, 1203, 1204, 1205, 1210, 1402, 1403, 1404, 1405, 1602, 1603, 1604, 1605, 1608, 1610, 2002, 2003, 2004, 2005, 2006, 2010, 2020, 2502, 2503, 2504, 2505, 2510, 2512, 2525, 3205, 3206, 3208, 3210, 3212, 3216, 4005, 4008, 4010, 4012, 4016, 5005, 5010, 5012, 5016, 5020, 6310, 6312, 6316, 6320, 8010, 8016, 8020, etc |

| Mating parts | Nut housing,ball screw support BK,BF,EK,EF,FK,FF,end maching service is available |

Notes:Above is part of standard models,other model or nut type is available upon drawing.For more information,pls contact the salesman.

| Our Advantages |

| Free service | Performance testing |

| Selection of auxiliary | |

| Technical solution | |

| Please contact the salesman for details | |

| Custom service | Stainless steel and other customized materials |

| Surface treatment | |

| Custom ballnut and shaft end machining | |

| Assembly | |

| Please contact the salesman for details | |

| Ball Screw Application |

Ball screws are more suitable for applications requiring smooth motion,efficiency,precision,precision and long continuous or high speed motion.The following figure shows the common application of ball screw.

Medical device

Solar pannel

Packging and injection mold

Woodworking machine

Machine centre

| Steel Ball Circulation Mode |

Floating

Floating

Cover plate type

The end cover type

Intubation type

Cutting type

1.Floating

Floating reversing device is the most basic and widely used,with the help of reversing device on the role of the bead groove,forcing the ball rolling along the raceway,over the screw thread raceway after the tooth tip,back to the initial raceway,formed a circular ball chain,suitable for all kinds of diameter and nut style.In all circulation systems,the nut diameter of the floating reversing device can be minimized,suitable for all kinds of precision micro equipment.

2.Cover plate type

Nut with cover plate,suitable for large lead ball screw,large load,high cost performance.

3.The end cover type

Refers to the way in which the steel ball rolls along the groove between the screw shaft and the nut,passes through the through hole on the nut through the path installed on the end cover backer at both ends of the nut,and returns to the original position.It has stronger scraping effect,and the strengthening of the circulating backflow structure increases the function of high rigidity and high speed.It is suitable for the design of high speed light load and low noise.

4.Intubation type

The intubation is an evolution from the floating deflector.To guide the balls into and out of the elbow tube by means of a tongue bevel at the end of the elbow tube inserted into the hole or other form of bead stopper.

5.Cutting type

Cutting type at the same time grasp the small space with two large load characteristics,processing difficulty is higher,is suitable for some special requirements.

| Cautions About Use of Ball Screw |

Ball screw assemblies are delicate components.Therefore,extra care must be taken to prevent the ball track from damages that caused by edged component or tools.Meanwhile,the steel ball is very easily fall out of the nut or over stroke.Don't disassemble it.Cautions About Use of Ball Screws:

To prevent steel ball fall out of the nut through the disassembly of screw and nut or over stroke,please be careful while operating.If the steel ball falls out,please contact with ALM Linear Motion for further instruction.Do not attempt to reassemble,which might cause permanent damage to the ball screw.If disassemble is required,please use a transfer pipe which has minor diameter than the screwdiameter to transfer the nut to prevent falling out of the steel balls.

| ALM Micro Ball Screw Catalog Download |

Other micro ball screw models are available,kindly pls refer to the catalog below.

ALM originally established in year of 2005.From a small factory,ALM nowadays has four production workshops for ball screw,lead screw,linear motor,linear actuator,linear guideways and related CNC machining parts for automation industry.Total areas over 7000 square meters,109 employees.Above 8 technical engineers are with over 20 years’ experience in linear motion filed.

ALM manufactures and supplies high quality linear motion components for customers in fields of aircraft, satellite,medical,Instrumentation,Robotics,Automobile,Electrical & Electronics,Textile,Medical,Food & Beverages,General Industry and so on.Customers cover more than 65 countries in Europe,North America,South Asia,Middle East,Africa,Latin America etc.With super quality and service,ALM has been widely recognized and highly valued by its high-end and picky customers, and thus remains at the top of their vendor lists.

ALM key production machines are imported,like high precision CNC grinding machine,3 axis,4 axis machining centre,internal and external grinding centre,CNC lathe.In addition,with advanced production management,ALM obtained the quality certificate ISO9001:2008 and IATF16949.And through our R&D department dedication over 16 years,we possess more than 26 national patents.

ALM's office

ALM's workshop

ALM product processing

ALM's warehouse

Customer Visit

ALM originally established in year of 2005.From a small factory,ALM nowadays has four production workshops for ball screw,lead screw,linear motor,linear actuator,linear guideways and related CNC machining parts for automation industry.Total areas over 7000 square meters,109 employees.Above 8 technical engineers are with over 20 years’ experience in linear motion filed.

ALM manufactures and supplies high quality linear motion components for customers in fields of aircraft, satellite,medical,Instrumentation,Robotics,Automobile,Electrical & Electronics,Textile,Medical,Food & Beverages,General Industry and so on.Customers cover more than 65 countries in Europe,North America,South Asia,Middle East,Africa,Latin America etc.With super quality and service,ALM has been widely recognized and highly valued by its high-end and picky customers, and thus remains at the top of their vendor lists.

ALM key production machines are imported,like high precision CNC grinding machine,3 axis,4 axis machining centre,internal and external grinding centre,CNC lathe.In addition,with advanced production management,ALM obtained the quality certificate ISO9001:2008 and IATF16949.And through our R&D department dedication over 16 years,we possess more than 26 national patents.

ALM's office

ALM's workshop

ALM product processing

ALM's warehouse

Customer Visit

Patent Certificate for invention and utility model

Patent Certificate for invention and utility model

1.Why can ALM be your better option for linear motion components?

With more than 16 years of industry experience,quality assurance,factory directly price.

2.What is your main products ?

Our Main products are consist of ball screw,linear guide,lead screw,linear module and linear motor.

3.When can I get the quotation?

We usually quote within 24 hours after we get your inquiry.If you are very urgent to get the price,please call us or tell us in your email so that we will regard your inquiry priority.

4.How to Custom-made?

1.Why can ALM be your better option for linear motion components?

With more than 16 years of industry experience,quality assurance,factory directly price.

2.What is your main products ?

Our Main products are consist of ball screw,linear guide,lead screw,linear module and linear motor.

3.When can I get the quotation?

We usually quote within 24 hours after we get your inquiry.If you are very urgent to get the price,please call us or tell us in your email so that we will regard your inquiry priority.

4.How to Custom-made?