- Home

- Products

- Video

- Blog

- Projects

- Quality Control

- About ALM

- News

- Support

- Contact Us

| Availability: | |

|---|---|

| Quantity: | |

Tr9x4

ALM

8483900090

Trapezoidal Tr9x4 Lead Screw with Anti-backlash Nut.In the anti-backlash nut,a small torsion spring is located in the sleeve and provides a preload force that forces the two nuts partially apart to compensate for the clearance.The lead screw can operate in very challenging environments,including some conditions that the ball screw cannot withstand.

| Screw Material | ASTM1045,SUS303,SUS304,SS316,SS316L |

| Nut material | Brass,Tin bronze,Phosphor bronze,Aluminum bronze,POM,PEK, nylon,POK,Stainless steel,1045,Zinc alloy,Brass+Plastic,Aluminum alloy+Plastic,Brass+Steel,Self lubricating(No oil type) |

| Quality standard | ISO2901-4,DIN103 |

| Clearance | 7e,higher precision is available upon request |

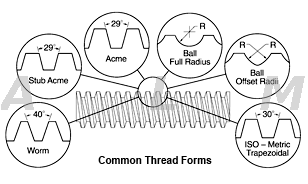

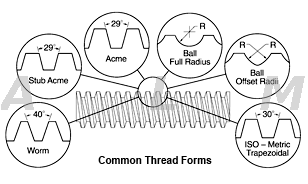

| Transmission Screw Thread Types |

Thread Types | Features |

| Trapezoidal thread | T ISO Trapezoldal Thread:For transmission and posltion adjustment,wldely used In the mechanical Industry. |

| Metric thread | M ISO Metric Thread (60°):The most common form of thread used for fastening and precislon transmission. |

| ACME thread | English threads can also be used for fastening connectlons,but not for high accuracy |

| Round thread | Wlth the same arc thread as ball screw,the transmission is smoother. |

| Goethe thread | Gothic double arc thread,drawing the advantages of ball screw,is the new products. |

| Reclprocating thread | X Reclprocating thread:A screw that makes the slldle block reclprocate without changing the rotation direction of the spindle. |

| Product Parameter |

A broad range of lead nuts are available,other nut type or size can be made upon drawing

When selecting the right nut for an application,there are a few things to keep in mind.Bronze nuts provide superior service at high working loads.They should be well lubricated with a good quality,Extreme Pressure(EP)grease compatible with the operating environment.Plastic nuts can be used without lubrication and are popular for low load applications.

Other ready models are available

| What’s the difference between lead screw designs? |

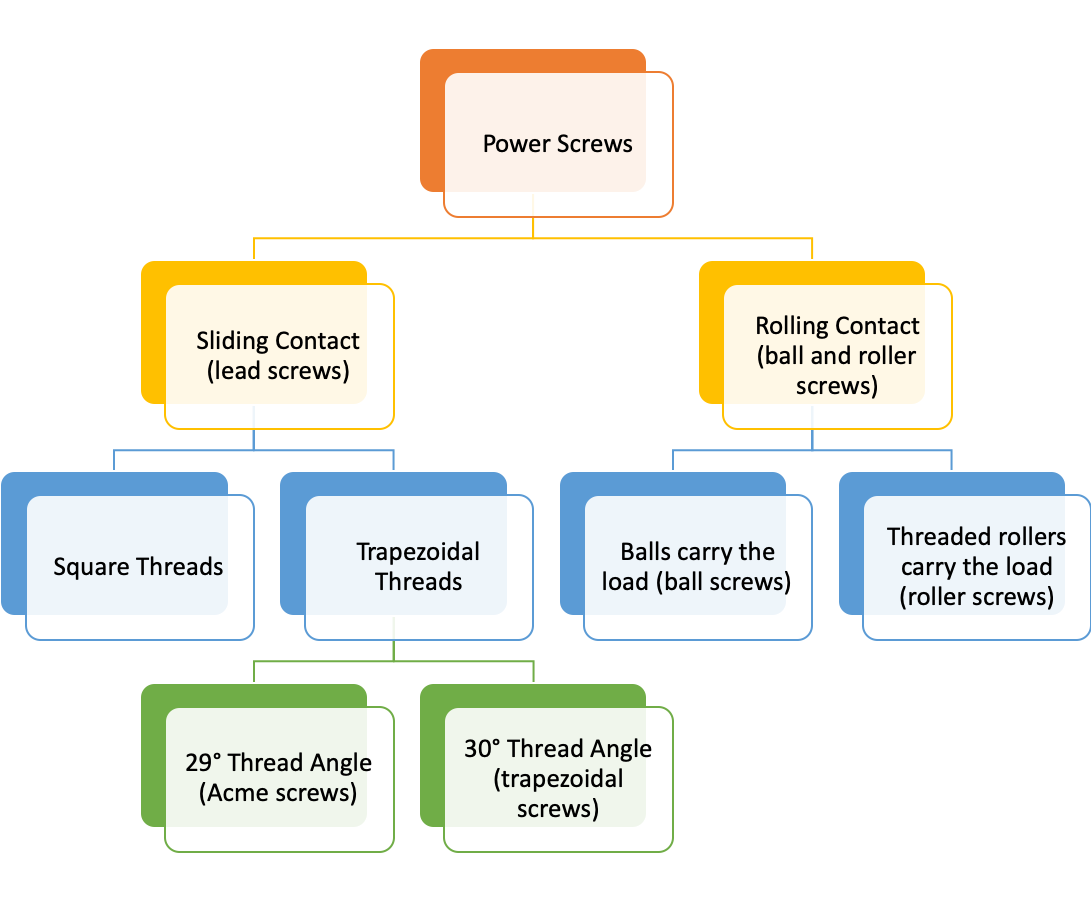

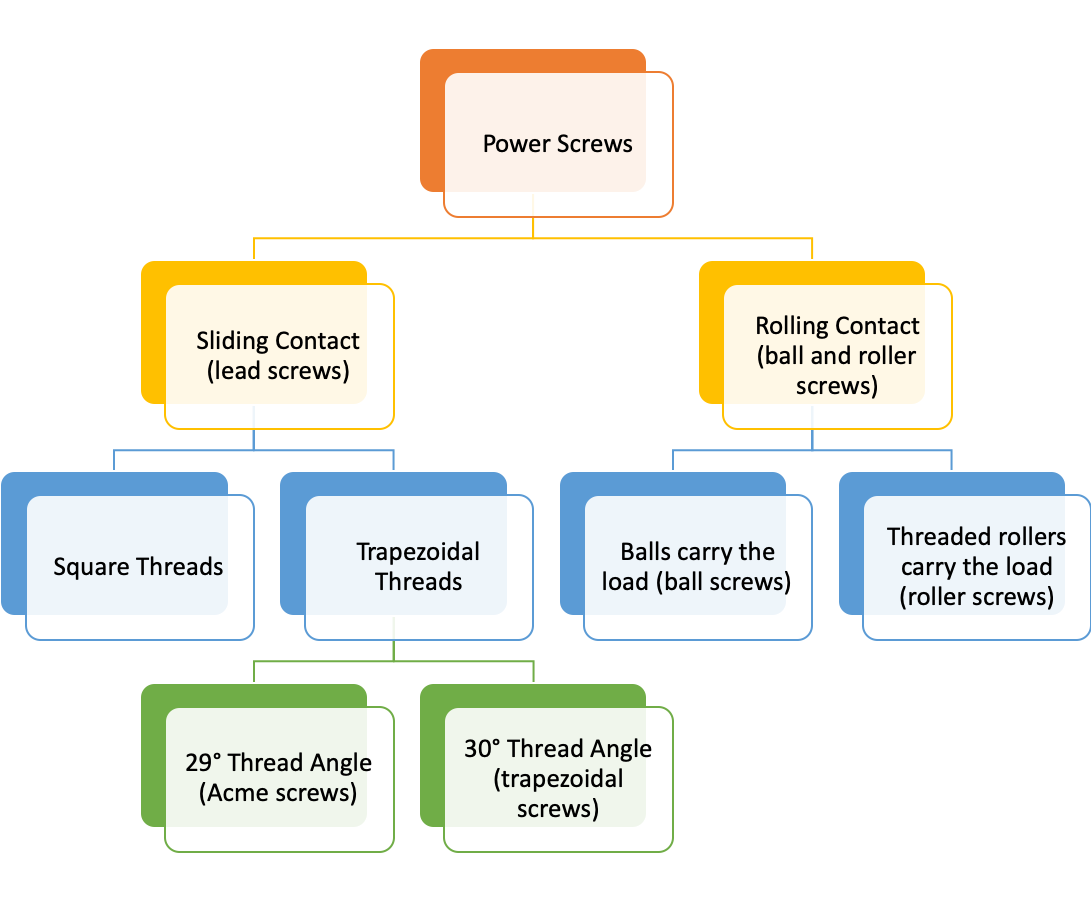

In power transmission applications,there are two main types of screw drives:screw drives that use a recirculating ball or roller for applications requiring high rigidity,excellent positioning accuracy,and high duty cycle ratio,and screw drives that rely on sliding contact for applications requiring corrosion resistance,self-locking operation,and customizable nut designs.

The second type - screw drivers with sliding contact between the nut and the screw shaft - is called lead screw,Acme screw or trapezoidal screw.Although these names are often used interchangeably,they actually refer to different screw geometrics and sizes.Here is a breakdown of the different types of sliding contact screws and what the terms "lead screw," "Acme screw," and "trapezoidal screw" really mean.

Lead Screws

The most commonly used of the three terms "lead screw" refers only to a powered screw that relies on the sliding motion between the nut and the screw shaft.There are two variations of the lead screw:the screw with square thread and trapezoidal thread.

Lead screw designs for power transmission use almost exclusively trapezoidal threads,which are easier to manufacture and have higher load capacity than screws with square threads.However,trapezoidal threads do have higher friction and are therefore less efficient than the square thread form.

The lead screw can have square or trapezoidal threads.

A power screw is a screw that transmits power by converting rotating motion into linear motion.The lead screw and ball screw are the types of power screws.

ACME Screws

As mentioned above,the lead screw for power transmission uses the trapezoidal thread form.But the trapezoidal screw design can be threaded at 29° or 30° angles,which means that the trapezoidal screw comes in two versions.

The first version(called the Acme screw)has a thread angle of 29° and is manufactured in inch size.Acme screw size is usually specified by the screw shaft diameter and the number of threads per inch or TPI.

Trapezoidal screw form with thread angle of 29°is called Acme screw,while trapezoidal screw form with thread angle of 30°is called trapezoidal screw.

Trapezoidal Screws

Trapezoidal screws also use the trapezoidal screw form of lead screw,but the trapezoidal screw thread angle is 30° and manufactured in metric size.The size of the trapezoidal screw is specified by the shaft diameter of the screw and the pitch of the screw thread.Trapezoidal screws are sometimes called "metric screw" or "metric Acme screw".

Acme screws and trapezoidal screws both use a trapezoidal thread form,but they have different thread angles.

Trapezoidal Tr9x4 Lead Screw with Anti-backlash Nut.In the anti-backlash nut,a small torsion spring is located in the sleeve and provides a preload force that forces the two nuts partially apart to compensate for the clearance.The lead screw can operate in very challenging environments,including some conditions that the ball screw cannot withstand.

| Screw Material | ASTM1045,SUS303,SUS304,SS316,SS316L |

| Nut material | Brass,Tin bronze,Phosphor bronze,Aluminum bronze,POM,PEK, nylon,POK,Stainless steel,1045,Zinc alloy,Brass+Plastic,Aluminum alloy+Plastic,Brass+Steel,Self lubricating(No oil type) |

| Quality standard | ISO2901-4,DIN103 |

| Clearance | 7e,higher precision is available upon request |

| Transmission Screw Thread Types |

Thread Types | Features |

| Trapezoidal thread | T ISO Trapezoldal Thread:For transmission and posltion adjustment,wldely used In the mechanical Industry. |

| Metric thread | M ISO Metric Thread (60°):The most common form of thread used for fastening and precislon transmission. |

| ACME thread | English threads can also be used for fastening connectlons,but not for high accuracy |

| Round thread | Wlth the same arc thread as ball screw,the transmission is smoother. |

| Goethe thread | Gothic double arc thread,drawing the advantages of ball screw,is the new products. |

| Reclprocating thread | X Reclprocating thread:A screw that makes the slldle block reclprocate without changing the rotation direction of the spindle. |

| Product Parameter |

A broad range of lead nuts are available,other nut type or size can be made upon drawing

When selecting the right nut for an application,there are a few things to keep in mind.Bronze nuts provide superior service at high working loads.They should be well lubricated with a good quality,Extreme Pressure(EP)grease compatible with the operating environment.Plastic nuts can be used without lubrication and are popular for low load applications.

Other ready models are available

| What’s the difference between lead screw designs? |

In power transmission applications,there are two main types of screw drives:screw drives that use a recirculating ball or roller for applications requiring high rigidity,excellent positioning accuracy,and high duty cycle ratio,and screw drives that rely on sliding contact for applications requiring corrosion resistance,self-locking operation,and customizable nut designs.

The second type - screw drivers with sliding contact between the nut and the screw shaft - is called lead screw,Acme screw or trapezoidal screw.Although these names are often used interchangeably,they actually refer to different screw geometrics and sizes.Here is a breakdown of the different types of sliding contact screws and what the terms "lead screw," "Acme screw," and "trapezoidal screw" really mean.

Lead Screws

The most commonly used of the three terms "lead screw" refers only to a powered screw that relies on the sliding motion between the nut and the screw shaft.There are two variations of the lead screw:the screw with square thread and trapezoidal thread.

Lead screw designs for power transmission use almost exclusively trapezoidal threads,which are easier to manufacture and have higher load capacity than screws with square threads.However,trapezoidal threads do have higher friction and are therefore less efficient than the square thread form.

The lead screw can have square or trapezoidal threads.

A power screw is a screw that transmits power by converting rotating motion into linear motion.The lead screw and ball screw are the types of power screws.

ACME Screws

As mentioned above,the lead screw for power transmission uses the trapezoidal thread form.But the trapezoidal screw design can be threaded at 29° or 30° angles,which means that the trapezoidal screw comes in two versions.

The first version(called the Acme screw)has a thread angle of 29° and is manufactured in inch size.Acme screw size is usually specified by the screw shaft diameter and the number of threads per inch or TPI.

Trapezoidal screw form with thread angle of 29°is called Acme screw,while trapezoidal screw form with thread angle of 30°is called trapezoidal screw.

Trapezoidal Screws

Trapezoidal screws also use the trapezoidal screw form of lead screw,but the trapezoidal screw thread angle is 30° and manufactured in metric size.The size of the trapezoidal screw is specified by the shaft diameter of the screw and the pitch of the screw thread.Trapezoidal screws are sometimes called "metric screw" or "metric Acme screw".

Acme screws and trapezoidal screws both use a trapezoidal thread form,but they have different thread angles.

Why can ALM be your better option for lead screws?

Why can ALM be your better option for lead screws?

ALM originally established in year of 2005.From a small factory,ALM nowadays own factory 7000 square meters,109 employees.Above 8 technical engineers are with over 20 years' experience in linear motion filed.

With the products covering more than 72 countries in Europe,North America,South Asia,Middle East,Africa,Latin America and Australia,New Zealand etc.With super quality and service,ALM has been widely recognized and highly valued by its high-end and picky customers,and thus remains at the top of their vendor lists.In year of 2016,our Dr team carryied out new innovation linear motor testing.

ALM key production machines are imported,like high precision CNC grinding machine,3 axis,4 axis machining centre,internal and external grinding centre,CNC lathe.With advanced production management enables ALM obtain the quality certificate ISO9001:2008 and IATF16949.The R&D achievements over many years bring ALM more than 26 national patents.

ALM's office

ALM's workshop

ALM lead screw processing

ALM's warehouse

ALM product show

Customer Visit

ALM originally established in year of 2005.From a small factory,ALM nowadays own factory 7000 square meters,109 employees.Above 8 technical engineers are with over 20 years' experience in linear motion filed.

With the products covering more than 72 countries in Europe,North America,South Asia,Middle East,Africa,Latin America and Australia,New Zealand etc.With super quality and service,ALM has been widely recognized and highly valued by its high-end and picky customers,and thus remains at the top of their vendor lists.In year of 2016,our Dr team carryied out new innovation linear motor testing.

ALM key production machines are imported,like high precision CNC grinding machine,3 axis,4 axis machining centre,internal and external grinding centre,CNC lathe.With advanced production management enables ALM obtain the quality certificate ISO9001:2008 and IATF16949.The R&D achievements over many years bring ALM more than 26 national patents.

ALM's office

ALM's workshop

ALM lead screw processing

ALM's warehouse

ALM product show

Customer Visit

Patent Certificate for invention and utility model

ISO certificate

Patent Certificate for invention and utility model

ISO certificate

1.Why can ALM be your better option for linear motion components?

With more than 16 years of industry experience,quality assurance,factory directly price.

2.What is your main products ?

Our Main products are consist of ball screw,linear guide,lead screw,linear module and linear motor.

3.How to Custom-made?

Step1:Send us your drawing for checking.We will check the production feasibility.Our specially trained engineers will help you find out the best solution based on rich projects experience.

Step2:We make our production drawing for your checking to avoid misunderstanding.And to ensure each dimensions comply with your requirements.

Step3:Prepare for sample

Step4:After samples approved on your prototype.Move to mass production

4.When can I get the quotation?

We usually quote within 24 hours after we get your inquiry.If you are very urgent to get the price,please call us or tell us in your email so that we will regard your inquiry priority.

1.Why can ALM be your better option for linear motion components?

With more than 16 years of industry experience,quality assurance,factory directly price.

2.What is your main products ?

Our Main products are consist of ball screw,linear guide,lead screw,linear module and linear motor.

3.How to Custom-made?

Step1:Send us your drawing for checking.We will check the production feasibility.Our specially trained engineers will help you find out the best solution based on rich projects experience.

Step2:We make our production drawing for your checking to avoid misunderstanding.And to ensure each dimensions comply with your requirements.

Step3:Prepare for sample

Step4:After samples approved on your prototype.Move to mass production

4.When can I get the quotation?

We usually quote within 24 hours after we get your inquiry.If you are very urgent to get the price,please call us or tell us in your email so that we will regard your inquiry priority.